Tool surface coating technology is a surface modification technology developed in response to market demand....

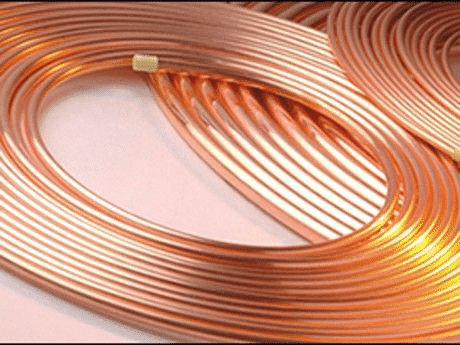

Base knowledge of titanium Titanium is an important structural metal developed in the 1950s. Titanium...

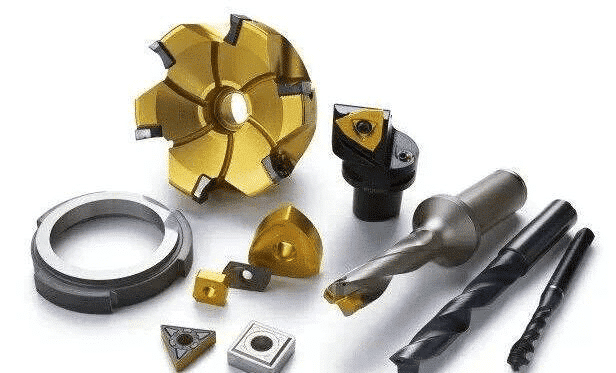

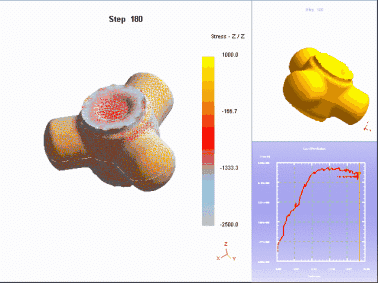

Cause of wear on Cutting tool include the following ones: Cutting tool materials Tool material...

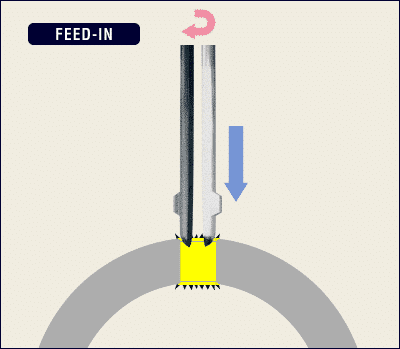

Let ‘s just cut into the case. What is cold extrusion? Cold extrusion of cold...

As we all know, there are many kinds of bearing materials in the market. There...

Burr in metal processing is a common problem, such as drilling, turning, milling, plate cutting....

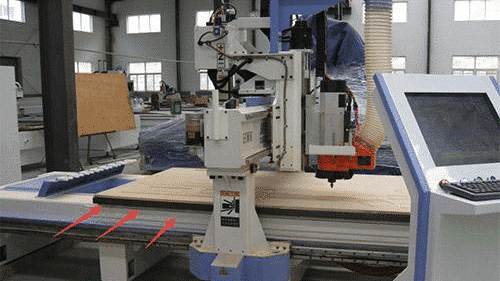

If you ask, “What’s the difference between CNC machining and 3D printing?” The most straightforward...

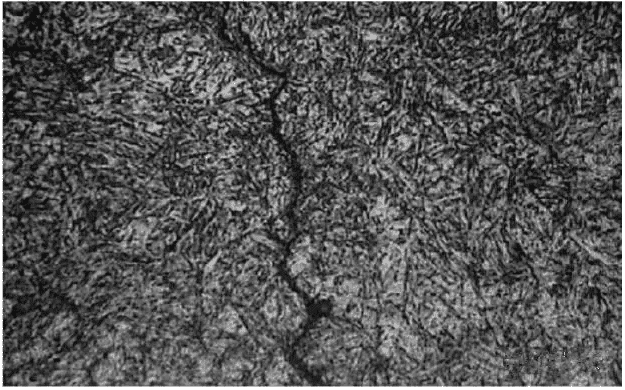

Quenching crack is a common quenching defect, which is caused by many factors. Because the...