Rookie on the operation of CNC machine often make CNC bump. It is a very wrong and harmful understanding to often hear others say that you can’t learn machine tool operation without hitting the machine.

CNC bump has great damage to the accuracy of machine tools, and the impact on different types of machine tools is also different. Generally speaking, the machine tool with weak rigidity has a greater impact, and the machine tool with gantry structure with strong rigidity has a smaller impact under the same impact force. If the machine tool is a cantilever structure, and the spindle is a machine tool structure installed on a rotating shaft, once the machine tool collides, the impact on the accuracy of the machine tool is fatal. Therefore, for high-precision CNC machine tools, collision must be absolutely eliminated. As long as the operator carefully controls certain anti-collision methods, the collision can be completely prevented and prevented.

From the perspective of processing operation process, NC machine tool processing can be divided into three modules: programming, tool setting and automatic processing. Among them, programming and tool setting are preparatory work for machining operations. Whether the programming is correct, whether the selected cutting parameters are reasonable, and whether the input of tool setting parameters is accurate will be shown in practical machining. Therefore, in order to ensure the accuracy of the processing operation of the NC machine tool, it is usually necessary to stop the trial processing, so as to test whether there are problems in the automatic processing of the NC machine tool. In the trial processing, strictly following the processing principle of “three looks, two needs, and one stop” can greatly reduce the collision problem in the operation of the machine tool.

Three looks about CNC bump

First, look at the program

All operations of CNC machine tools are controlled by program instructions. After checking program statements and program names, find out the existing problems and correct them in time. When checking the program, in order to prevent repeated inspection or missed inspection, we should follow a certain inspection order: first, from the perspective of the program name, because the completion of the basic NC operation requires a large number of program instructions to stop control, a large number of program files will also be stored in the system of the single chip microcomputer, and the program name will be lowered in the automatic way, especially pay attention to the suffix of the program name and the program format; Secondly, check the program fragment. Computer software simulation is applied to detect whether there are errors in the detailed program statements. If there is a problem in the upper and lower logic of the statement writing, the simulation software will automatically point out the existing problems, so that programmers can stop the program correction in time until there is no problem in the operating program.

Second, look at the workpiece coordinates

Detailed information such as the machine coordinate and workpiece coordinate of the current tool will be displayed on the screen. When stopping the inspection, pay attention to comparing the screen value with the actual tool tip position to ensure that the coordinate values between the two can correspond one by one. Due to the influence of machine tool fixtures, tool wear and other factors, workpiece coordinates often have certain errors. If the error exceeds the specification range, it will affect the machine tool processing progress and cause collision problems. Therefore, through the comparison of workpiece coordinates, this problem can be effectively prevented.

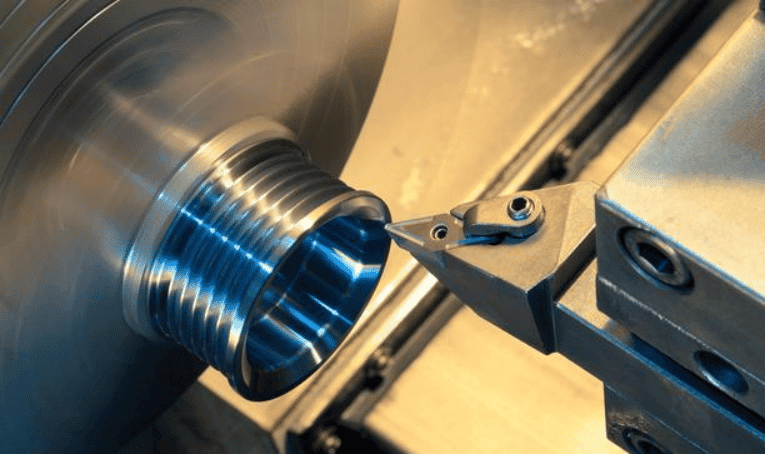

Third, look at the position of the knife tip

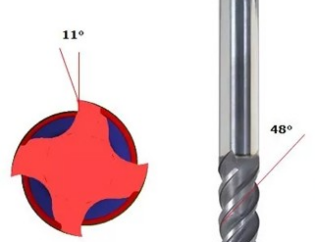

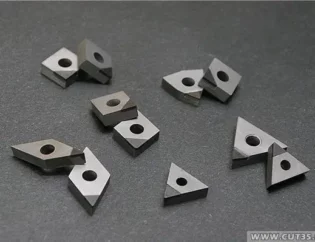

The machining and cutting operations of the NC machine tool are completed by the tool, so when stopping the machine tool inspection, we should focus on checking the position of the tool tip. The tool tip will show wear after being used for a period of time. On the premise of not affecting the machining quality of the machine tool, the machine tool operator should regularly adjust the tool position to avoid the tool colliding with the workpiece or chuck. In addition, it is also necessary to compare the practical position of the tool tip with the data displayed on the screen. If there is a large error between the two values, the processing operation should also be stopped, and the tool should be exited after shutdown, and then re installed and adjusted.

Two points about cnc bump

First, single stage execution

CNC machine tools have the function of single-stage SBL execution. After starting this function, each time the single-chip microcomputer completes a control program, it will automatically terminate the processing operation. It is required that the operator of CNC machine tools manually start the next program to start the processing operation. The advantage of single-stage execution is that it gives operators sufficient inspection time, including tool inspection, coordinate inspection and program inspection, so as to prevent the occurrence of collision accidents to a great extent. Although single-stage execution reduces the processing efficiency of CNC machine tools, it can significantly improve the processing quality and prevent collision problems. In contrast, its overall processing effect is better.

Second, low magnification

By adjusting the speed adjustment knob of the NC machine tool and reducing the feed speed of the tool, you can check whether the tool tip position and the coordinate display value are different before the tool stops machining the workpiece. If the two values are different, you can shut down the equipment in time to prevent collision problems. Especially in the machining of the inner hole of the workpiece, it is easy to present the error of feeding or withdrawing the tool, which not only affects the machining quality of the inner hole, but also leads to the serious deviation of the inner hole size of the workpiece, and also presents the problems of knife pricking and knife collision. Therefore, the selection of low magnification processing speed can effectively prevent the above processing problems.

One stop

To be precise, it should be suspended repeatedly in the process of automatic processing. After a pause, the operator can observe the display of the position of the tool tip and the screen coordinates, especially when the chip is wrapped on the workpiece or tool, he can press the cycle stop key, and use this period of time to deal with the problems in the processing of the NC machine tool, so as to avoid mistakes due to panic in the operation.

In addition, before operation, the operator should receive safety training for machine tool operation. Each type of machine tool should have safety operation procedures. The operator should receive systematic operation and safety training, and can work on the machine tool only after holding a qualified work license. Before work, you should know the location of the fire extinguisher and control the application method of the fire extinguisher. The position of the air pressure switch of the machine tool, the position of the switch of the input power of the machine tool, and the position of the hydraulic workstation should all control the emergency shutdown method. For the grinder using cooling oil, the fire extinguisher should be placed within three meters of the machine tool.