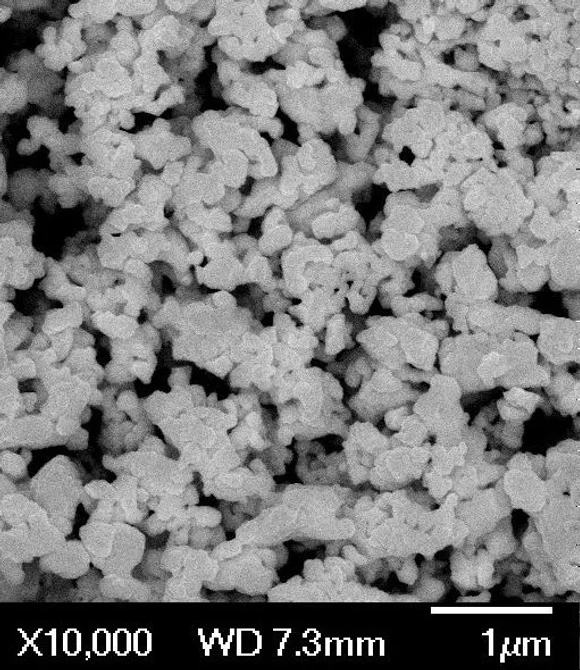

What is ultra-fine grain tungsten carbide ? Ultra-fine grain cemented carbide is a high hardness,...

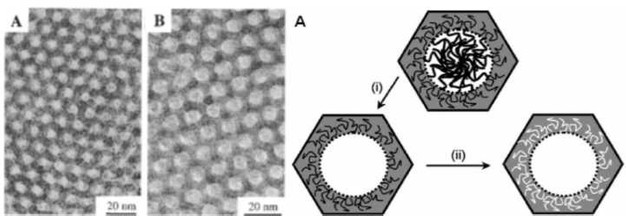

UPAC separates pores into micropores (<2 nm), mesopores or mesopores (2 to 50 nm), macropores...

Continuously plastically deformed main working parts and tools on the rolling mill. The roller consists...

Cemented carbide(hardmetal) is a general term for alloys composed of carbides, nitrides, borides, or silicides...

The progressive die is composed of multiple stations. Each station is connected in sequence to...

1. The contradictory characteristics of traditional uniform carbide Cemented carbide is a typical brittle material....

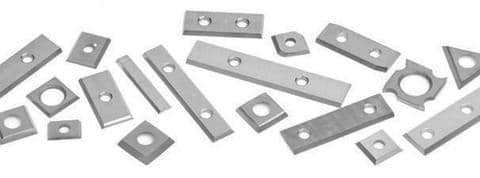

Machining is one of the most basic, widest and most important processes in the wood...

Cemented carbide is a composite material composed of high-hardness refractory metal carbides and cemented metals....

1. CVD Diamond Introduction Chemical Vapor Deposition (CVD) diamond refers to the use of CVD...

CNC lathe machining is a kind of high-precision, high-efficiency machine tool with digital information control...