Carbide rods, due to their special properties of wear resistance, high hardness, excellent fracture toughness, and compressive strength, have been widely used in various fields such as metal processing, electronics industry, wood processing, aerospace industry, and medicine. They are ideal preliminary materials for manufacturing printed circuit board micro-drills, milling cutters, reamers, step tools, long rod tools, taps, and dot matrix printer needles. With the development of technology, the demand for carbide rods is increasing, and forming techniques have evolved from traditional processes such as cold isostatic pressing and die pressing to more modern and economical extrusion molding processes, resulting in better quality and a wider variety of products.

Sintering of carbide is a crucial step in the production of carbide. During the pressing process...

There are mainly two types of 3D printing technologies currently applied in tool manufacturing. One...

Aluminum alloy is a general term for alloys with aluminum as the base. The main...

What is carbide? carbide is an alloy material made through powder metallurgy process, consisting of hard...

Carbide heat treatment is a critical process that plays a crucial role in enhancing the...

The knowledge of carbide grade identification will be shared in this article.Carbide is renowned for...

Mining carbide need to be able to drill rapidly under high-power impact conditions while minimizing...

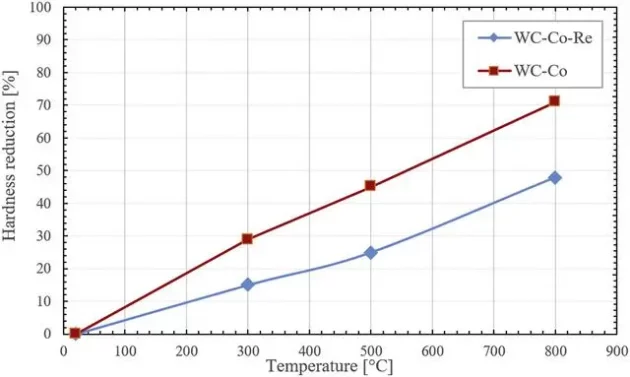

Coarse-grain WC powder possesses special properties and specific uses, especially high-temperature coarse-grain WC, which boasts...

Hyper carbide = hyper alloy + cemented carbide It is well known that there are...