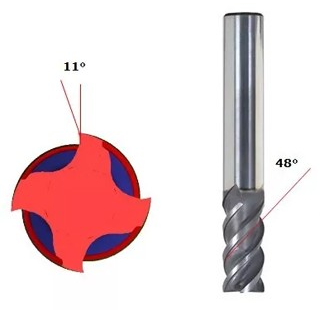

What milling cutter should be used for processing stainless steel? This is a question encountered...

The processed product is a bevel gear with 16 φ17 through-holes, made of sticky metal...

To discuss the problem of fatigue and fracture of cemented carbides, we must first understand...

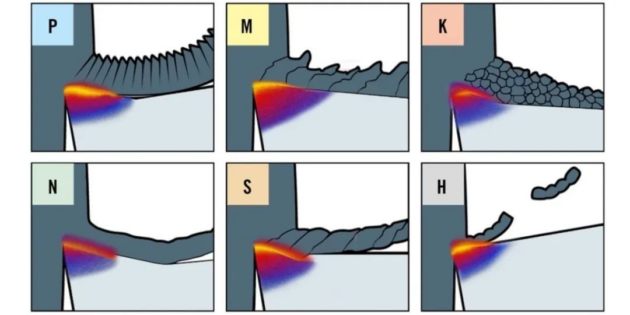

This is an overview of the most common single-tool wear failures in cutting tools. These...

In machining process, the formation and evacuation of chips are crucial as they ensure the...

Hard turning (turning instead of grinding) refers to the process of using turning methods for...

With its high strength, good mechanical properties, and strong corrosion resistance, titanium alloy is increasingly...

Machining centers are generally divided into two parts: machine tool (mechanical part) and control system...

As we know, traditional turning machining involves a stationary tool and a rotating workpiece, while...

Causes of Milling Cutter Wear Milling cutter wear is primarily attributed to two main categories,...