Cemented carbide has a history of more than 80 years since it came out as an important tool material and structural material in 1923. Over the past 50 years, especially since China’s reform and opening up, China’s cemented carbide industry has become a real large cemented carbide producer. However, when we are immersed in the achievements we have made, we should also clearly see the hidden worries in the development, seriously think with a high sense of responsibility, and strive to explore the way to eliminate the worries, so as to ensure the sustainable development of China’s cemented carbide industry.

Développement rapide de l'industrie du carbure cémenté en Chine

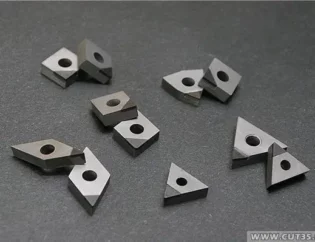

China’s cemented carbide industry basically started from the establishment of Zhuzhou Cemented Carbide plant in the 1950s by introducing a full set of technology and equipment from the former Soviet Union. In the long planned economy era, after many years, a series of advanced equipment and technologies in the cemented carbide production process, such as high-efficiency ball milling, spray drying granulation, high-precision automatic press, vacuum sintering equipment, pressure sintering equipment, grinding coating equipment and high-precision mold manufacturing, can be basically solved in domestic manufacturers. Foreign advanced equipment and domestic advanced equipment have been applied in different cemented carbide manufacturers to varying degrees. The technology and equipment level of tungsten smelting and milling production in China has reached the international advanced level. In the 21st century, the CNC carbide blade production line of Zhuzhou Diamond Cutting Tools Co., Ltd., which is controlled by Zhuzhou Cemented Carbide Group Co., Ltd., is designed and built according to the advanced level of contemporary carbide production in terms of environment, equipment, process technology and quality standards, laying a good foundation for the development of high value-added CNC carbide blades and tools in China.

In addition, the deep-processing technology of China’s cemented carbide industry has also developed to a certain extent. The production proportion of three series of deep-processing products of cemented carbide cutting tools, geological and mineral tools and wear-resistant parts in cemented carbide production enterprises has gradually increased. In 2005, the proportion of deep-processing products of cemented carbide enterprises has reached more than 10% of the total production of cemented carbide. More and more cemented carbide manufacturers have introduced advanced deep-processing technology and equipment from abroad, or developed deep-processing technology and equipment by themselves and established professional deep-processing production lines. The former, such as cemented carbide micro drilling and integral tool processing, and the latter, such as top hammer and roll processing lines, have played a good role in technological progress and economic benefit improvement of enterprises.

Trois problèmes dignes d'attention dans l'industrie du carbure cémenté

1. Développement aléatoire de produits de qualité moyenne et inférieure et concurrence désordonnée

Since 2004, China’s annual output of medium and low-grade cemented carbide has reached about 16000 tons, accounting for about 40% of the world’s annual output of cemented carbide. However, it is unimaginable that China’s cemented carbide production capacity has exceeded the annual output of 28000 tons, and the production capacity is less than 60%. What is more frightening is that new factories producing medium and low-grade cemented carbide are still emerging, and the production capacity continues to increase. This phenomenon leads to vicious competition among enterprises, which can not be avoided. In addition to a big price war, all kinds of non-standard competition behaviors such as kickbacks, fake and shoddy products, and local policies can be found everywhere. The bad result is that the enterprise has low efficiency and can not increase the investment in science and technology, which seriously affects the technological progress of the industry. Even the enterprises with strong technical strength also suffer from the difficulties caused by history. They do not control resources, do not regulate their competitiveness, and are forced to stay on the survival line, which has seriously damaged the development ability of high-grade and high value-added cemented carbide products.

2 Développement lent des produits haut de gamme

The development level of such products in a country or an enterprise reflects the development level of cemented carbide in that country or enterprise to a certain extent. For example, Israel is a small country. Israel’s iska factory only produces more than 300 tons of cemented carbide annually. However, their proud high-performance CNC cemented carbide blades and cutters sell well all over the world, with an annual sales of more than 1billion US dollars, which is two to three times that of Zhuzhou factory with an annual output of more than 4000 tons of cemented carbide, fully demonstrating the status of a powerful cemented carbide producer and a strong enterprise.

As far as domestic manufacturers are concerned, Zhuzhou Cemented Carbide Group Co., Ltd. is undoubtedly the most important manufacturer of such products. Its “diamond” brand was rated as the only domestic brand among the top ten “most popular domestic tool brands” and “the most competitive tool brands in the Chinese market”. However, compared with foreign advanced manufacturers, the competitiveness of Zhuzhou Diamond Industrial Park is not strong.

Prenant l'exemple des lames CNC de haute précision et de haute performance, les lames de tour de l'usine de Zhuzhou sont fondamentalement complètes, mais elles préfèrent les produits d'usinage grossier et d'usinage de semi-précision, alors qu'il existe un grand écart entre l'usinage de précision et les produits d'usinage d'ultra précision. . Lors du fraisage des lames, la différence entre les lames d'usinage conventionnelles est très faible, mais il existe des différences entre le fraisage de précision et les lames d'usinage de grandes pièces. Il existe un certain jeu entre les autres lames, telles que les lames d'usinage de filetage, les lames d'usinage d'engrenages, les lames de brochage, les lames de coupe, etc. Outre le jeu des lames NC, le plus gros problème est que l'appariement des outils vient de commencer.

De cette façon, nous ne pouvons remplacer les lames importées que dans une certaine partie ou lien de traitement, il est donc difficile d'entrer dans la chaîne de production automobile avancée, ce qui limite considérablement la promotion et l'application des produits. Grâce à une technologie de pointe et à des installations de support complètes, les fabricants avancés étrangers peuvent répondre aux exigences d'un ensemble complet de lames et de couteaux pour la chaîne de traitement. Il leur est ainsi plus facile de prendre en charge de grosses commandes de lames et de fraises pour des lignes d'usinage de haut niveau dans l'industrie manufacturière.

The gap between China’s Cemented Carbide numerical control blades and cutting tools and foreign advanced level is finally reflected in product production and product promotion and application, but the reasons for these gaps are various:

(1) la ligne de production des couteaux doit être mise à jour

the production of cutters is out of line. For decades, the production of cutters in China has been separated, and the problem of mutual matching has not been considered. This situation continues. The production of cutters and cutters by foreign advanced manufacturers is integrated. They often take the cutter design as the source, closely linked to study the tool matching, and constantly introduced new supporting tools when they continuously introduced new cutters. At present, some tool factories in China are introducing foreign cutting tool production technology and products, but they do not consider the problem of matching with domestic cutters. As a result, it is still equipped with other people’s cutters instead of domestic cutters. The production and development of domestic cutters and cutters are restricted.

(2)pas de marque célèbre

the national standard for cutters is not sound. At present, China’s national standards for cutting tools are not perfect, and the imported cutting tools are open. Therefore, there are various kinds of imported cutting tools, and the cutting tools used are often restrained by which standard. On the contrary, the export of cutters and cutters in China is restricted by foreign standards. If this problem is not solved, it is not conducive to the export of China’s cutters and cutting tools, nor to the popularization and promotion of China’s advanced CNC cutters and cutting tools.

(3)fourniture d'outils de coupe avancés à main courte

une attention insuffisante est accordée à la promotion des outils de coupe avancés. De nombreuses entreprises de fabrication en Chine sont loin d'être suffisamment conscientes de la promotion et de l'application des fraises NC avancées. S'ils ne réalisent pas l'application d'outils de coupe avancés, ils disposeront d'une technologie de traitement avancée. Dans les pays manufacturiers développés au niveau international (comme les États-Unis, le Japon et l'Allemagne), la consommation annuelle moyenne de machines-outils est d'environ $4milliards de dollars, tandis que la consommation d'outils de coupe est d'environ $2milliards de dollars. En 2005, la consommation de machines-outils en Chine était proche de 10 milliards de dollars américains, tandis que la consommation d'outils de coupe n'était que d'environ 1,3 milliard de dollars américains, ce qui est loin derrière la proportion de consommation de machines-outils dans les pays développés. De nombreuses entreprises sont disposées à acheter des machines-outils à commande numérique avancées, mais elles ne sont pas disposées à dépenser de l'argent pour résoudre les problèmes d'application des outils de coupe avancés. Ils achètent des équipements de traitement avancés et utilisent partout des outils de coupe à l'envers, ce qui affecte également le processus de développement des outils de coupe avancés.

(4) application de l'outil par semaine

China’s CNC cutter and cutter manufacturers still lack the concept that cutters and cutters must also have high efficiency. They cannot provide the best application technology for their products like foreign advanced manufacturers. Therefore, they cannot give full play to their application functions of advanced cutters and cutters. This has also affected the promotion and application of CNC cutters and cutters in China.

(5) contenu technologique de production insuffisant

The production of high-precision and high-performance CNC cutters and tools involves the research on cemented carbide materials, tool structure and groove, coating technology, equipment automation and intelligence, tool processing technology and tool application technology. Its production technology is much more difficult than ordinary medium and low grade cemented carbide production. In order to catch up with foreign counterparts in talent and talent allocation, China’s production enterprises must strive to achieve this goal through the long-term unremitting efforts of all parties concerned.

3. faibles retombées économiques industrielles

The problems existing in the development of China’s cemented carbide industry will inevitably lead to the low economic benefits of enterprises, which is seriously restricting the sustainable development of the industry. Some of the world’s leading cemented carbide enterprises, such as Sweden’s Sandvik tool company, the United States’ Kenner company, Israel’s iska company, etc. in 2005, the turnover of cemented carbide and cemented carbide tools of the above three companies was about 2.6 billion, 2billion and 1billion dollars respectively.

En 2005, le chiffre d'affaires de l'industrie du carbure cémenté en Chine était d'environ 9 milliards de yuans, soit moins de 50% du chiffre d'affaires des outils Sandvik.

In 2005, Sandvik Tools Co., Ltd. realized a profit of about 560million US dollars, with an operating profit margin of 21%, while the profit of China’s cemented carbide industry was about 540million yuan, with an operating profit margin of about 6%, which was also less than one eighth and one third of Sandvik Tools Co., Ltd.

La raison de la faible efficacité de l'industrie du carbure cémenté en Chine est en fait étroitement liée aux problèmes existant dans le développement ci-dessus.