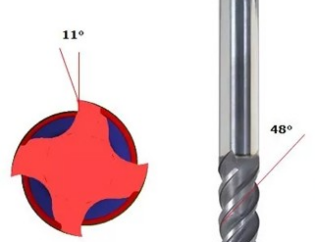

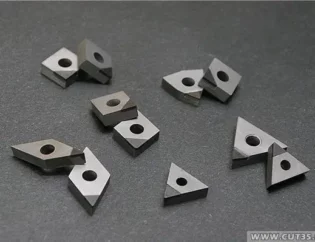

Starting in the 1920s, metal products, toys, and small hardware industries used punches, presses, and other simple mechanical equipment and corresponding molds to process product blanks or certain components, including “knifehead molds” for blanking and punching. "Docking mold" for metal stretching. At that time, the stamping equipment used by the factories was not very powerful, and most of them were still wrenched. In addition to the use of a small amount of simple general-purpose equipment, the mold processing is mainly manual, so the accuracy of the mold is not high, and the damage rate is large. It was not until the early 40s that hydraulic press cold punches appeared. With the production of a large number of stamping machine tools, from 1960 to 1970, cold stamping dies have been developed from single blank blanking and single punching dies to blanking and punching composite dies. Because of the appearance of the standard parts of the cold die frame, a variety of mold design structures are available, and the precision is also improved. At the same time, with the advancement of heat treatment technology and the improvement of detection methods, the service life of cold punching die is increased by 5 to 7 times. During this period, due to the successive use of machine tools such as forming grinding, electric pulse and wire cutting machines, and hard alloys as mold materials, the manufacturing process of cold punching molds has seen new development. The service life of cemented carbide cold punches has jumped from 35,000 to more than 1.5 million. As the designers improved the molding process, a large number of compound molds with automatic feeding, automatic sheeting and picking devices were introduced. After the introduction of the mold milling machine, the plaster core, the wood mold or the real object can be used to make the core of the same shape, which provides convenience for the production of the compound drawing mold and ensures the accuracy. After the 1970s, the cold die was machined using a slant line cutting machine. The punches and dies could be quenched and then cut and assembled to replace the original cold die making process: heat processing – assembly – deformation correction of the cumbersome process . The mold finish is also increased by one level and the accuracy can reach 0.01 mm. Later, the professional mold factory, mold workshop team has been widely used wire cutting machine processing cold stamping die.1、Introduction of powder compacted carbide diePowder pressed cemented carbide molds, also known as metal powder pressing molds, powder metallurgy molds and hard alloy molds, have high hardness (minimum 85.0HRA, up to 92.0HRA), high strength, good wear resistance, good toughness, impact resistance , Electrical processing performance, full system density, high internal cavity finish for a wide range of applications, non-stick red features, it is made of hard alloy material by precision grinding press mold, can greatly improve the surface quality of the product, its The service life is 5-10 times that of ordinary steel press dies. It is suitable for the most ideal hard alloy molds for magnetic powder, ceramic powder, refractory metal powder, iron-copper-based powder, copper, iron, aluminum, zinc, stainless steel and other metal powder materials. Has been widely used in electronics, automobiles, motorcycles, machinery, household appliances, aviation, aerospace, shipbuilding and other fields.The materials used to make stamping dies include steel, carbide, steel cemented carbide, zinc-based alloys, low-melting-point alloys, aluminum bronzes, and polymer materials. At present, most of the materials used to make stamping dies are steel. The types of common mold working parts include: carbon tool steels, low alloy tool steels, high carbon high chromium or medium chromium tool steels, medium carbon alloy steels, and high speeds. Steel, base steel, carbide, hard alloy steel and so on.The application of more carbon tool steels in the mold is T8A, T10A, etc. The advantages are good processing performance and low price. However, the harden ability and red hardness are poor, heat treatment deformation is large, and the bearing capacity is low.2. Low alloy tool steel Low-alloy tool steels are based on carbon tool steels with appropriate amounts of alloying elements. Compared with the carbon tool steel, the quenching deformation and cracking tendency are reduced, the hardenability of the steel is improved, and the wear resistance is also better. Low-alloy steels used to make molds include CrWMn, 9Mn2V, 7CrSiMnMoV (code CH-1), and 6CrNiSiMnMoV (code GD).3. High carbon and high chromium tool steel Commonly used high-carbon high-chromium tool steels are Cr12 and Cr12MoV, Cr12Mo1V1 (code D2), they have good hardenability, hardenability and wear resistance, heat treatment deformation is very small, high wear resistance micro-deformation die steel, bearing The ability is second only to high speed steel. However, segregation of carbides is severe, and repeated forging (axial boring, radial plucking) must be performed for forging to reduce the non-uniformity of carbides and improve the service performance.4. High carbon medium chromium tool steel The high-carbon medium-chromium tool steels used in the molds include Cr4W2MoV, Cr6WV, Cr5MoV, etc. They have lower chromium content, less eutectic carbides, uniform carbide distribution, small heat treatment distortion, good hardenability and dimensional stability. Sex. The performance is improved compared to high carbon high chromium steels where carbide segregation is relatively severe.5. High speed steelHigh-speed steel has the highest hardness, wear resistance and compressive strength in die steels, and it has a high load carrying capacity. Commonly used in the mold are W18Cr4V (code 8-4-1) and W6Mo5 Cr4V2 (code 6-5-4-2, U.S. brand M2) containing less tungsten, and vanadium-reduced high-speed steel developed to improve toughness. 6W6Mo5 Cr4V (code 6W6 or low carbon M2). High-speed steel also needs to be forged to improve its carbide distribution.6. Base steel Add a small amount of other elements to the basic ingredients of high-speed steel, and increase or decrease the carbon content to improve the performance of the steel. Such steels are collectively referred to as base steels. They not only have the characteristics of high-speed steel, have a certain degree of wear resistance and hardness, and fatigue strength and toughness are better than high-speed steel, high-strength cold working tool steel, the material cost is lower than high-speed steel. The matrix steels commonly used in molds include 6Cr4W3Mo2VNb (code 65Nb), 7Cr7Mo2V2Si (code LD), and 5Cr4Mo3SiMnVAL (code 012AL).7. Cemented Carbide and Steel Cemented CarbideHard alloys have higher hardness and wear resistance than any other type of die steel, but have poor bending strength and toughness. The cemented carbide used as a mold is a tungsten-cobalt type, and a mold having a small impact resistance and a high wear resistance is required, and a hard alloy containing a relatively low amount of cobalt may be used. For high impact molds, carbides with high cobalt content can be used.Steel cemented carbide is made by adding a small amount of alloying element powder (such as chromium, molybdenum, tungsten, vanadium, etc.) as binder to iron powder, and using titanium carbide or tungsten carbide as the hard phase, which is sintered by powder metallurgy. The steel cemented carbide substrate is steel, which overcomes the disadvantages of poor toughness and processing difficulties of the cemented carbide, and can be cut, welded, forged and heat-treated. Steel-bonded carbides contain a large amount of carbides. Although the hardness and wear resistance are lower than those of cemented carbides, they are still higher than those of other steels. After quenching and tempering, the hardness can reach 68 to 73HRC. Carbide die is more than ten times or even several times as long as the life time of the steel die. The hard alloy die only has high hardness, high strength, corrosion resistance, high temperature resistance and small expansion coefficient. Generally tungsten carbide is used as the hard alloy.Such as the market standard materials YG3, YG6, YG6X.YG8.YG15, YG20, YG20C, YG25 and HU20, HU222, HWN1 (non-magnetic alloy mold), etc., using the original carbide material, low pressure sintering and other special processes, the toughness will be more than the conventional production Better, the service life will increase 3-5 times.classificationCemented carbide molds can be divided into four categories depending on their use:The first category is carbide drawing dies, which account for most of the carbide die. China’s current wire drawing die’s major grades YG8, YG6, YG3, followed by YG15, YG6X, YG3X, developed some new grades, such as the new grade YL for high-speed wire drawing, and the drawing die number CS05 imported from abroad (YLO.5 ), CG20 (YL20), CG40 (YL30); K10, ZK20/ZK30.The second type of mold is cold heading cold die and plastic die, and the main brands are YC20C, YG20, YG15, CT35 and YJT30 and MO15.The third type of mold is a non-magnetic alloy mold for the production of magnetic materials, such as YSN series YSN (including 20, 25, 30, 35, 40) and steel joint non-magnetic die TMF.The fourth type is the hot die. There is no standard grade for such alloys and the market needs to increase.Applicable to cold heading cold punching of copper, aluminum, steel, alloy steel material standard parts, screws, rivets, etc., flat head cold heading die, countersunk head cold heading die, a sequence of punching die, shrink rod die and other commonly used models.1. Adopt 99.95% high purity raw material tungsten carbide powder and cobalt.2. The hardness of the cold heading mold reaches HRA88 or more, and the bending strength reaches 2400 or more.3. Has a high wear resistance with impact resistanceIngredients (select tungsten carbide powder + cobalt powder according to applicable requirements) → fully mix → pulverize → dry → add molding agent after sifting → re-dry → sieving to obtain mix → mix granulation, pressing → forming → (Germany Imported Vacuum Low-pressure Sintering Furnace) Sintering → Sintered Roughcast → Inspection (Nondestructive Ultrasonic Testing) → Drawing Design → Mold Set and Die Set Inlaying or Welding → Electromachining (Electrode-Welding or Wire Cutting) Machining → Grinding and Polishing → Pliers Repair → trial mode → packing.Third, powder pressed carbide die technical parameters1, WC and other alloy components%: 88.0.2. Co content %: 12.0.3, density g/cm3: 13.4 to 14.8.4, hardness HRA: 85.0 ~ 91.5.5, grain size um: 1.0 ~ 1.8.6, bending strength MPa: 2800 ~ 4000.7. Elastic modulus GPa: 390-525.8. Thermal expansion coefficient 10-6/0C: Impact toughness J/cm2: 4.9-6.8.Resources:Our Tungsten Carbide Wear PartsOur Tungsten Carbide Cold Heading DieOur Tungsten Carbide Wire Drawing Die

Fonte: Meeyou Carbide

Fonte: Meeyou Carbide