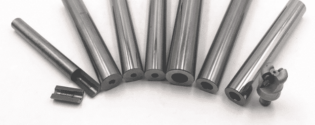

超硬ソリッドシャンク

ねじ付き円筒形超硬エクステンションシャンク固体超硬エクステンションシャンクはねじ込み式モジュールエンドミルに広く使用されており、その振動防止特性によりねじ式モジュール式エンドミルの寿命を効果的に改善し、より正確なフライス加工能力を提供できます。焼結HIP。高度なコンピューター制御のHIP炉は、より高密度の構造を得るために、焼結プロセス中により多くの圧力を提供するために適用されます。パウダーエクセレント。ドイツのHCStarckとの深い協力のおかげで、私たちはカーバイドロッド製造用のすべての標準グレードに対して、カーバイドロッドに世界最高の粉末を使用しています。 ThreadConectionカーバイドエクステンションシャンクは、交換可能なモジュラーエンドミルにねじ込むことができ、その防振特性により、より長い時間を提供できます...

続きを読む→

クーラント穴付き超硬ロッド

クーラント オイルダクト付きタングステンカーバイドロッド ストレートクーラント穴付きの超硬ロッドとヘリカルクーラント穴付きの両方の超硬ロッドが付属しています。グレード違いの在庫もございます。内部の冷却穴により、はるかに効率的な切りくず排出とより深い穴あけ能力が得られます。深穴ドリルやスレッドエンドミルに広く使用されています。中央クーラントホール付き超硬ロッド タイプD(mm)d(mm)穴位置の偏差≦(mm)L(mm)DTol.dTol.LTol.OD4.0×ID1.0×3304.0+0.2/+0.61.0±0.150 .23300/+5OD5.0×ID1.0×3305.0+0.2/+0.61.0±0.150.23300/+5OD5.0×ID1.5×3305.0+0.2/+0.61.5±0.150.23300/+5OD6. 0×ID1.0×3306.0+0.2/+0.61.0±0.150.23300/+5OD6.0×ID1.5×3306.0+0.2/+0.61.5±0.150.23300/+5OD8.0×ID1.0× 3308.0+0.2/+0.61.0±0.150.253300/+5OD8.0×ID1.5×3308.0+0.2/+0.61.5±0.150.253300/+5OD9.0×ID1.0×3309.0+0.3/+0.71 .0±0.150.253300/+5OD10.0×ID1.0×33010.0+0.3/+0.71.0±0.150.253300/+5OD10.0×ID2.0×33010.0+0.3/+0.72.0±0.20.253300 /+5OD11.0×ID1.0×33011.0+0.3/+0.71.0±0.150.253300/+5OD12.0×ID1.0×33012.0+0.3/+0.71.0±0.150.253300/+5OD12.0× ID2.0×33012.0+0.3/+0.72.0±0.20.253300/+5OD14.0×ID2.0×33014.0+0.3/+0.72.0±0.20.253300/+5OD16.0×ID2.0×33016.0+ 0.4/+0.82.0±0.20.253300/+5OD16.0×ID3.0×33016.0+0.4/+0.83.0±0.250.253300/+5OD18.0×ID3.0×33018.0+0.4/+0.83.0 ±0.250.33300/+5OD20.0×ID3.0×33020.0+0.4/+0.83.0±0.250.33300/+520.0≤Dia≤40.0はリクエストに応じて利用可能ストレートクーラント穴2個タイプD(mm)TK(mm)d(mm)穴位置偏差≦(mm)L(mm)DTol.(mm)TKTol.dTol.(mm)LTol.(mm)OD4.3×2ID0 .8×1.8×3304.30/+0.61.8-0.4/00.8±0.100.153300/+10OD5.3×2ID0.8×2.0×3305.30/+0.62.0-0.4/00.8±0.100.203300/+10OD6.3 ×2ID1.0×3.0×3306.30/+0.63.0-0.5/01.0±0.150.203300/+10OD7.3×2ID1.0×3.5×3307.30/+0.63.5-0.5/01.0±0.150.203300/+10OD8 .3×2ID1.0×4.0×3308.30/+0.64.0-0.6/01.0±0.150.203300/+10OD9.3×2ID1.4×4.0×3309.30/+0.64.0-0.6/01.4±0.150.203300/ +10OD10.3×2ID1.4×5.0×33010.30/+0.65.0-0.6/01.4±0.150.203300/+10OD11.3×2ID1.4×5.0×33011.30/+0.65.0-0.6/01.4±0.150. 283300/+10OD12.3×2ID1.75×6.0×33012.30/+0.66.0-0.6/01.75±0.150.303300/+10OD13.3×2ID1.75×6.0×33013.30/+0.66.0-0.6/01.75± 0.150.343300/+10OD14.3×2ID1.75×7.0×33014.30/+0.67.0-0.6/01.75±0.150.373300/+10OD15.3×2ID2.0×7.0×33015.30/+0.67.0-0.6/ 02.0±0.200.373300/+10OD16.3×2ID2.0×8.0×33016.30/+0.68.0-0.6/02.0±0.200.403300/+10OD17.3×2ID2.0×8.0×33017.30/+0.88.0- 0.6/02.0±0.200.473300/+10OD18.3×2ID2.0×9.0×33018.30/+0.89.0-0.6/02.0±0.200 .503300/+10OD19.3×2ID2.0×9.0×33019.30/+0.89.0-0.6/02.0±0.200.503300/+10OD20.3×2ID2.5×10.0×33020.30/+0.810.0-0.8/02.5 ±0.250.503300/+1020.0≦Dia≦40.0はお問い合わせください/-0.3≦0.0815.8916.3216.77±0.23OD4.3×2ID0.6×2.2×3304.32.330.6±0.152.20/-0.3≦0.1021.1921.7722.36±0.31OD5.3×2ID0.7×2.6×3305.32 .670.7±0.152.60/-0.4≦0.1326.4927.2127.95±0.38OD6.3×2ID0.7×2.6×3306.32.50.7±0.152.60/-0.4≦0.1531.7932.6533.54±0.46OD6.3×2ID1 .0×2.6×3306.32.51.0±0.152.60/-0.4≦0.1531.7932.6533.54±0.46OD7.3×2ID1.0×3.7×3307.32.51.0±0.153.70/-0.4≦0.1537.0938.0939.13± 0.54OD8.3×2ID1.0×4.0×3308.32.51.0±0.154.00/-0.4≦0.1542.3843.5344.73±0.62OD8.3×2ID1.0×3.5×3308.32.51.0±0.153.50/-0.4≦ 0.1542.3843.5344.73±0.62OD8.3×2ID0.6×2.8×3308.32.50.6±0.152.80/-0.4≦0.1542.3843.5344.73±0.62OD9.3×2ID1.4×4.8×3309.32.51.4±0.154 .80/-0.6≦0.2047.6848.9750.32±0.69OD10.3×2ID1.4×4.8×33010 .32.751.4±0.154.80/-0.6≦0.2052.9854.4155.91±0.77OD10.3×2ID0.7×2.6×33010.32.750.7±0.152.60/-0.4≦0.2052.9854.4155.91±0.77OD10.3 ×2ID1.0×3.0×33010.32.751.0±0.153.00/-0.4≦0.2052.9854.4155.91±0.77OD10.3×2ID1.4×5.0×33010.32.751.4±0.155.00/-0.6≦0.2052.9854.4155. 91±0.77OD11.3×2ID1.4×5.3×33011.32.751.4±0.155.30/-0.8≦0.2858.2859.8661.5±0.85OD12.3×2ID1.4×6.25×33012.32.751.4±0.156.250/- 0.8≦0.3063.5865.367.09±0.92OD12.3×2ID1.75×6.0×33012.32.751.75±0.206.00/-0.8≦0.3063.5865.367.09±0.92OD13.3×2ID1.75×6.5×33013.35.01.01. ±0.206.50/-0.8≦0.3468.8770.7472.68±1.00OD14.3×2ID1.75×7.1×33014.33.51.75±0.207.10/-0.8≦0.3774.1776.1878.27±1.08OD14.3×2ID0.8 ×3.5×33014.33.50.8±0.153.50/-0.4≦0.3774.1776.1878.27±1.08OD14.3×2ID1.4×4.5×33014.33.51.4±0.154.50/-0.6≦0.3774.1776.1878.27±1.081OD5 .3×2ID1.75×7.7×33015.33.51.75±0.207.70/-0.8≦0.4079.4781.6283.86±1.15OD16.3×2ID1.75×8.3×33016.33.51.75±0.208.30/-0.8≦0.4084. 7787.0689.45±1.23OD16.3×2ID2.0×8.0×33016.33.52.0±0.208.00/-0.6≦0.4084.7787.0689.45±1.23OD17.3×2ID1.75×8.9×33017.33 .51.75±0.208.90/-0.8≦0.4790.0792.595.04±1.31OD18.3×2ID2.0×9.55×33018.33.52.0±0.259.550/-0.8≦0.5095.3697.95100.63±1.38OD18.3×2ID1 .75×9.15×33018.33.51.75±0.209.150/-0.8≦0.5095.3697.95100.63±1.38OD19.3×2ID2.0×10×33019.33.52.0±0.2510.00/-0.8≦0.50100.66103.2±910 1.46OD20.3×2ID2.0×10.4×33020.33.52.0±0.2510.40/-1≦0.50105.96108.83111.81±1.54注: D<18.3, L>100, L公差0~+7; L<100、L Tolerance0~+5。 D≧18.3、L公差+3~+10。 2 つのヘリカル クーラントを備えた超硬ロッド

続きを読む→

超硬ロッドブランク

固体の粉砕されていない炭化タングステンロッドブランクの焼結HIP。高度なコンピューター制御のHIP炉は、より高密度の構造を得るために、焼結プロセス中により多くの圧力を提供するために適用されます。パウダーエクセレント。ドイツのHCStarckとの深い協力のおかげで、私たちはカーバイドロッド製造用のすべての標準グレードに対して、カーバイドロッドに世界最高の粉末を使用しています。リードタイムファースト。押出、自動プレス、冷間静水圧プレスを含む3つの異なる圧縮方法が、超硬ロッド製造の最大効率のために使用されます。標準330mm長さ、メートル法、単位ミリメートル直径の許容差長さの許容差直径の許容差長さの許容差直径の許容差長さの許容差0.5 + 0.20 / + 0.45 ‐0.0 / + 10.0 9.5 + 0.20 / + 0.45 ‐0.0 / + 10.0 ...

続きを読む→

切削工具ブランク

カットツーレングス(CTL)炭化タングステンロッド、研磨済み、研磨済み、片面取り工具ブランクを切削するための研磨済みCTLカーバイドロッドの最大かつ最も完全なラインの1つがあります。 Meetyou Carbideは、工具ブランク用のこの種のロッドに対して最高の費用対効果を達成したことを誇らしげに発表します。ドイツのHCStarckの最高品質のパウダーと組み合わせた独自のプレス技術を使用しているためです。 h6ポリッシュ。直径の標準許容差は、h6研磨です。また、お客様の要件に応じて、h5研磨またはその他の許容差を提供することもできます。長さカット高度なワイヤー切断とダイヤモンドホイール切断の両方を適用して、カーバイドロッドを...

続きを読む→