Maybe you’ve heard people should never ever drill a hole with an end mill if there isn’t already a hole at the center for the chips to clear. Why can’t the end mill clear the chips? If the answer is no. How can you plunge with an end mill to produce a pocket as done by drill bit?

What is the main difference between drill bit and end mill?

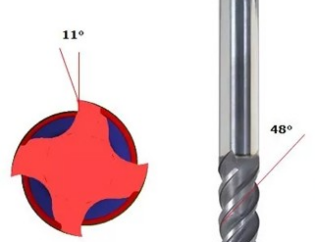

As the subtitle indicates, the two kinds of tools are significantly different. Firstly, they vary in tool geometry. End mill’s cutting part is wrapped around flutes, which are a bunch of helical grooves on side of end mills. Each flute is with a sharp edge at least. While you can’t see this kind of component on drill bits cause they merely use the edges on its top area instead of lateral cutting edge to drill down and evacuate chips. Secondly, End mill is more versatile than drill bit. End mills are devised for not only cutting horizontally on work piece but also primarily making a groove then broaching the whole hole based on the groove afterwards. Whereas drill bits’ can be only applied for boring straight hole down to material. In a word, drill bit can’t be replaced with end mill to accomplish milling operation.

what situation would you better consider applying drill bit on?

If you want to drill a hole less than 1.5mm in diameter, use a drill. End mills less than 1.5 mm become quite vulnerable and therefore cannot operate as vigorously as a drill.

If you need to drill a very deep hole – more than 4 times your hole diameter, choose a drill. Because if the hole diameter exceeds this value, it may be very difficult for the end milling cutter to remove the chips, which will quickly wear your tool and your workpiece.

Do you need to drill many holes in the workpiece at the same time? The drill may be the best. In most cases, the use of end mills for drilling is the fastest.

Do you need to make a very precise hole? Although milling is generally perfectly acceptable, sometimes tolerances require a drill and a reamer to achieve a perfect finish.

When should you use end mill?

Do you need to dig a big hole? Big hole needs big drill and big horsepower, which is the highlight of spiral milling. Use a milling cutter with a diameter of 60-80% of the hole diameter to clean up quickly, while leaving enough space for debris to escape.

Need to level the bottom hole on the workpiece? Ordinary drills can’t do this, so you’d better erase this item from the drill’s work list.

Need to produce a lot of holes of different sizes? Try to use end milling cutter, which can save time and space of tool changing.

Remember to ramp it side to side in or helical interpolation ramp

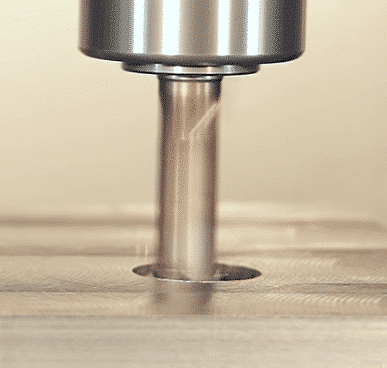

To answer this question have a look at the end of an end mill that is ground for center cutting. The clearance behind the bottom cutting edges is much less than the clearance behind the side cutting edges. There is simply not enough space for a chip to occupy and also there is no way for the chip to get out. If you do very, very short pecks you can drill with and endmill but it is much better to ramp down in a helical path. For doing a pocket it will be best to predrill a hole but if you want to avoid a tool change instead of drilling with the endmill slot down using a little ramp back and forth. Move the tool sideway about 1/2 its diameter while going down about 1/8 the diameter; this creates room for the chips to get out. It is not ideal but it works.

They leave a very nice finish on the inside of the hole. You will have to go slower than a drill, but there’s no problem evacuating the chips. Mostly, it’s done when you want a flat bottom hole such as a counterbore. As far as depth of plunge, about half the tool diameter is standard. Sometimes more or less to end up with the least amount of passes to achieve final depth.

Also, thin materials can easily be drilled with endmill, where a drill bit would grab and tear at the piece, the endmill just sizzles through it and leaves a round hole rather than a triangular one.