The correct lubrication method can improve the performance of the equipment and prolong its working life. Any equipment can not do without lubrication. But in actual production, there will be a misunderstanding of lubrication due to various reasons, such as thinking that oil can be lubricated, the viscosity of oil is greater, the effect is better and so on. In order to avoid damage to the machine caused by wrong operation, this paper introduces nine common mistakes for your reference.

01. The purpose of lubrication is to make the machine run faster

The contact surface of the relative moving parts in the machine will produce friction and wear. According to statistics, more than 1 / 3 of the world’s energy consumption is in friction loss. When the wear exceeds the allowable limit, it directly affects the normal operation and service life of the machine. Therefore, lubricant is added between the relative moving parts to form a lubricating oil film to reduce friction and reduce wear. At the same time, it can also play the role of cooling, buffering, vibration absorption and sealing.

The purpose of lubrication is not only to make the machine run faster, but also to ensure the normal operation and prolong the service life of the machine.

02. Mistakenly think that oil can lubricate

There are different kinds of lubricating oils and their working properties. In order to improve some properties of lubricating oils, the corresponding additives should be added.

In order to make the machine get reasonable lubrication, different types of lubricating oil and additives should be selected for different types, different working conditions and different oil supply methods.

Therefore, it can not be considered that any oil can be lubricated. What’s more, improper selection of lubricating oil will also cause lubrication accidents, which accounts for a large proportion of equipment failures.

03.The more lubricating oil, the better the lubrication effect

In case of grease lubrication, excessive resistance will increase, causing bearing heating, leading to grease leakage, especially for high-speed and heavy-duty machines.

Generally, oil level indicator can be used to show the height of oil level. For example, the immersion depth of the high-speed gear in the gearbox is 1-2 teeth high, so as to avoid poor lubrication of the high-speed gear, and reduce the movement resistance and oil temperature rise of the gear. Generally, the filling amount of grease for rolling bearing does not exceed 1 / 3-1 / 2 of bearing clearance.

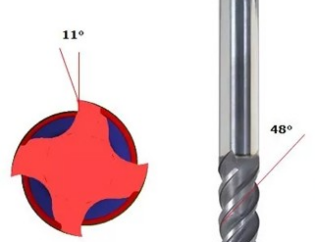

04. The higher the viscosity of lubricating oil, the better the lubrication effect

Viscosity is the main index of lubricating oil, and its standard is usually determined at the temperature of 100 ℃. The higher the brand, the thicker the lubricating oil film formed. Although the friction force of friction surface is reduced, the resistance is increased, the power loss is increased, and the waste of energy is increased.

When the machine is just started, the temperature is low, and part of the lubricating oil on the friction surface will be lost due to the increase of temperature after working for a period of time. The lubrication can not form an effective lubricating oil film and the oil can not be quickly replenished to the friction surface of the machine. Due to the high viscosity and slow flow of the oil, the wear of the parts is large.

Some data show that 15% fuel can be saved by reducing the viscosity of lubricating oil by 1 mm 2 / s. The selection of viscosity should consider the working speed, working temperature and other factors. Low viscosity of lubricating oil is one of the measures to save oil.

05. Unchanged oil selection according to the oil grade specified in the equipment manual

Most of the equipment managers believe that the oil specified by the equipment manufacturer is the law. In fact, the oil specified in the manual refers to the general working conditions, which may not be suitable for the actual working conditions, so it should be selected flexibly according to the actual conditions.

06. If the lubricating oil turns black, it means that the lubricating oil has deteriorated

If the lubricating oil turns black, it means that the lubricating oil has deteriorated and should be changed. This understanding is one-sided. For example, it is normal for machinery oil with detergent dispersant to turn black soon after use. It is not easy to think that the oil has deteriorated. The lubricating oil added with additives often produces a dark protective oil film on the bearing surface. It is normal to blacken the bearing surface in the process of use. It is not necessary to remove the blackened lubricant. Therefore, to determine whether the lubricating oil is deteriorated, comprehensive analysis should be carried out to change the oil according to its quality.

07. Used lubricating oil cannot be used and must be discarded

In fact, in addition to the rotten oil, there are more lubricating oil can be used.

The replaced oil, if only mixed with impurities, can be reused after precipitation and filtration;

After simple treatment, the oil with heavy pollution can be used as lubricant for rough processing equipment, antirust for outdoor equipment, or the waste oil can be collected and turned over for waste oil recycling

The oil that is difficult to be recycled can be burned as fuel oil after simple treatment.

08. All lubricating oils can be used interchangeably

The selection of lubricating oil depends on the working conditions, working environment, specific characteristics of friction surface and lubrication mode of the machine, and the type and brand of lubricating oil selected are also different, which cannot be replaced in general.

09. Do not replace or replenish lubricating oil for a long time

After using for a period of time, the performance of lubricating oil decreases or changes. With the decline of oil quality, if the lubricating oil is not replaced or supplemented in time, the lubricity is poor and high temperature is easy to occur.

In addition, many people lengthen the oil change cycle of air compressor in order to save money, but in fact, poor lubrication will cause large current, serious waste of power, and increase the operation cost, which is not worth the loss.