Classification of cutting fluids

Proportion by processing type and application:

According to morphology, there are liquid cutting fluid and solid lubricant. There are two kinds of liquid cutting fluids commonly used in production: Oil-based cutting fluid (cutting oil) mainly used for lubrication and water-based cutting fluid (cutting fluid) mainly used for cooling.

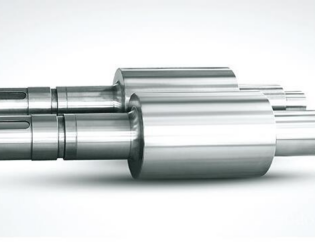

Oil based cutting fluid: oil based cutting fluid, also known as cutting oil, its basic composition is base oil (mineral oil or synthetic oil). When using, it doesn’t need to be diluted, and the stock solution is used directly. Additives include oily agents, extreme pressure agents (such as chlorine, sulfur, phosphorus, etc.), corrosion inhibitors, antioxidants, etc.

Water based cutting fluid is the most widely used cutting fluid at present, and its products account for about 70% of the total market share of cutting fluid. Water based cutting fluid needs to be diluted with water and then used. According to the diluted state, it can be divided into emulsion cutting fluid, microemulsion cutting fluid and synthetic cutting fluid.

Function and composition of liquid cutting fluid

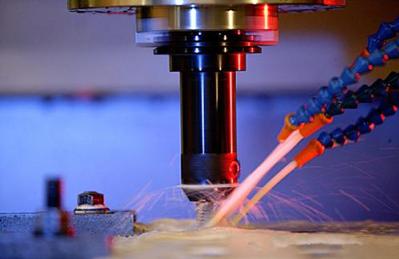

The main functions in machining are cooling, lubrication, cleaning and rust prevention. Because of the convection and vaporization of the liquid, the surface temperature of the cutting tool and the workpiece can be reduced, so as to prevent the surface burn and deformation of the workpiece. In addition, cutting fluid should have foam resistance and mould resistance, so that it can discharge no pollution to the environment, do harm to human body and use economy. For this reason, special additives should be added to the cutting fluid, such as oiliness agents (adsorbed on the surface of the workpiece to form oil film), extreme pressure agents (forming strong chemical membranes at high temperature and high pressure, anti friction and anti caking), rust inhibitor (preventing metal corrosion), defoamer (preventing foaming when cutting fluid is sprayed), and anti oxidant (to prevent cutting oil at high temperature). Reduction oxidation), surfactant, etc.

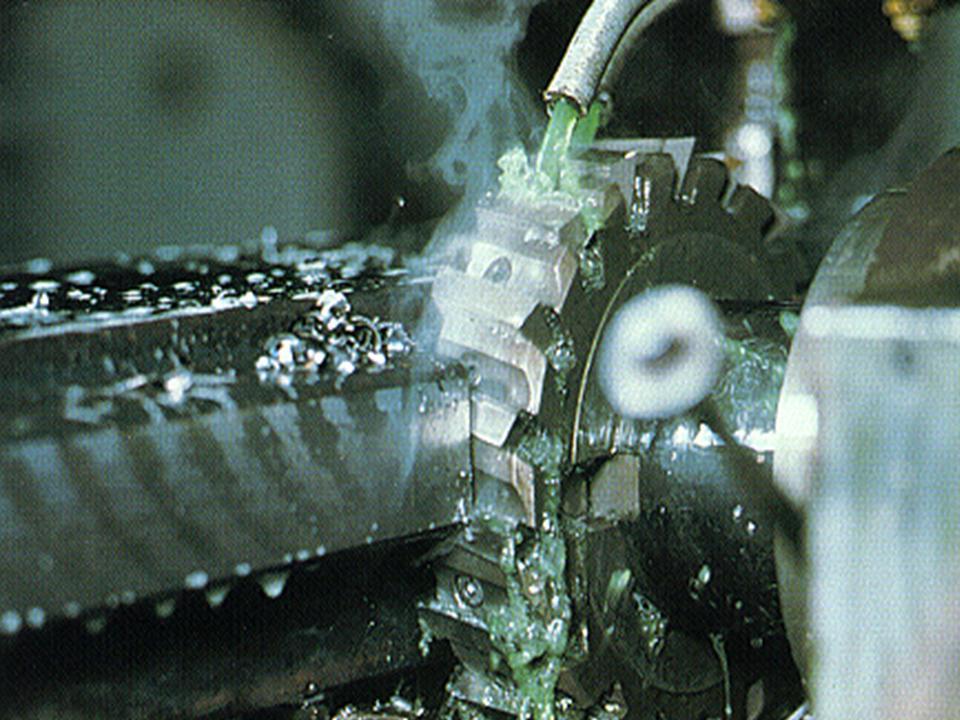

There are three kinds of oil mist in the process of liquid cutting fluid

(1) Clean oil mist produced by jet impact, free of solid dust;

(2) Smoke generated by evaporation or burning due to high temperature of heating or high speed cutting;

(3) Oil mist containing grinding dust produced by metal cutting fluid jet during grinding.

Impact of cutting coolant on health

Many people have a wrong idea about the toxicity of cutting fluid. They think that the greater the odor, the greater the toxicity. In fact, there is no absolute relationship between the two. Does cutting fluid have an impact on human health?

1) Can cause asthma and other respiratory diseases

According to the literature, the composition of metal cutting fluid is complex, and the additives and pollutants may be used as stimulating factors to induce sudden asthma, worsen the original condition of asthma, or cause airway discomfort in patients without asthma. Among the four kinds of metal cutting fluids, soluble oil and pure oil are associated with asthma. Pure oil, soluble oil and synthetic oil have been confirmed to cause airway dysfunction and respiratory diseases due to inhalation. Even if the concentration of the oil mist is only 0.41-0.55mg/m3, long-term exposure to the oil mist will lead to chronic bronchitis, chest discomfort and airway irritation.

However, due to the surge in the number of workers suffering from allergic pneumonia in recent years, the fact that long-term exposure to oil mist can lead to pneumonia has been studied and confirmed. The research data on the effect of metal cutting fluid oil mist on the lung function of workers are still scarce. One of the reasons is that most of the observed decline of lung function is irrecoverable. In addition, the decline of lung function is related to the amount of oil mist, which is the result of long-term accumulation. However, the results of animal experiments showed that dogs exposed to 5-100mg / m3 oil mist for more than 12 months would have fatty alveolar and macrophage granuloma, and the respiratory tissue showed morphological changes.

2) Carcinogenicity

Another harm of metal cutting fluid oil mist is its carcinogenicity. The carcinogenicity of metal cutting fluid mainly depends on the concentration of additives, pollution and service conditions. At present, there is no research on the carcinogenicity of metal cutting fluid for human, but the experimental research on animals shows that the oil mist of cutting fluid can cause skin tumor / skin cancer, stab tumor, lung cancer and pancreatic cancer. There are still many controversies about the carcinogenicity of cutting fluid oil mist: Although many epidemiological studies have reported the carcinogenic tendency of metal cutting fluid and its oil mist, due to the long incubation period of cancer, epidemiological studies can only evaluate the harm caused by a certain substance 20-30 years ago. For this reason, some researchers point out that the composition of metal cutting fluid decades ago can not represent the situation of today’s cutting fluid. In particular, great changes have taken place in the refining process, and PAHs and other undesirable components have been removed to a greater extent. Therefore, it is not appropriate to extend the previously proven carcinogenic tendency to the current cutting fluid. However, due to the complexity of the composition of metal cutting fluid, it is very difficult to simply prove that it is not carcinogenic.

3) Genetic influence

Compared with the research on other health hazards, the research on the influence of cutting fluid oil mist on genetics is the least. According to the results of Fuchs j et al. In 1995, N-nitrosodiethanolamine (ndela) was identified as 2B carcinogen by IARC. Ndela strongly affects DNA strand breaks in monocytes. The number of DNA strand breaks in workers exposed to air with ndela concentration more than 500 mg / m3 was significantly higher than that exposed to air with ndela concentration less than 50 mg / m3. Although EPA (U.S. Environmental Protection Agency) has banned ndela as additive of metal cutting fluid, under the action of nitrosylating agent, triethanolamine (tea) and diethanolamine (DEA) can still react to form ndela in metal cutting fluid.