Thread formation and construction

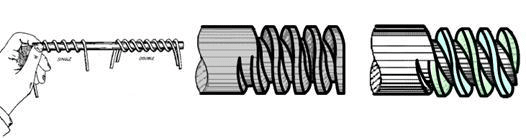

(1) The formation of screw thread: a point on the cylindrical surface makes constant rotation movement around the axis of the cylinder, and at the same time, it also makes constant linear movement along a straight line. The trajectory of this composite movement is the helix.

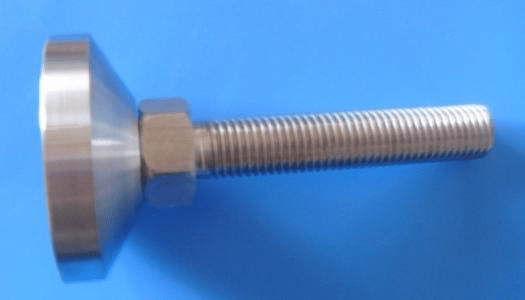

(2) Thread structure: the convex part of the thread is called the top of the tooth, and the groove part is called the bottom of the tooth. In order to prevent the thread from damage at the end during installation, the thread shall be processed into tapered chamfer or spherical rounding at the beginning of the thread. At the end of the thread there is a runout or undercut.

Structural element of thread

(1) profile: made of triangle. Trapezoid, zigzag, square, etc.

(2) Nominal diameter: refers to the diameter representing the specification and size of the thread, generally refers to the major diameter of the thread. D (external thread) or D (internal thread).

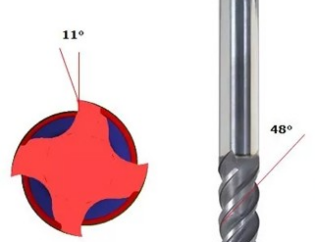

(3) Number of lines: threads are divided into single line and multi line. The thread formed along one helix is called single line thread; the thread formed along two or more helixes is called multi line thread. In n.

(4) Pitch and lead: the axial distance between the two adjacent threads on the pitch diameter line corresponding to the two points, called pitch, expressed as P. The axial distance between two adjacent teeth on the pitch diameter line corresponding to two points on the same helix is called the lead, which is expressed in S. It can also be understood as the distance raised by turning a circle. For single thread, the lead is equal to the pitch, i.e. s = P. Multi thread s = n × P.

(5) Direction of rotation: the direction of rotation of the thread can be divided into left and right. The screw in when rotating clockwise is right-hand thread; the screw in when rotating counterclockwise is left-hand thread. When connecting internal and external threads, the above elements must be the same before they can be screwed together. The three elements of thread: profile, diameter and pitch are the most basic elements to determine the thread. If the three elements meet the national standards, they are called standard threads; if the profile meets the standards, but the diameter or pitch does not meet the standards, they are called special threads; if the profile does not meet the standards, such as square thread, they are called non-standard threads. 3. Type of thread connection thread: common thread with triangular profile.

Transmission thread: trapezoid thread, serrated thread and square thread. 4. The structure classification thread distributed on the outer surface of the parent body is called external thread, and the inner surface of the parent body is called internal thread. The thread formed on the cylindrical body is called cylindrical thread, and the thread formed on the conical body is called conical thread. The connection is mostly single line, and the transmission is double line or multi line; according to the size of the teeth, it can be divided into coarse thread and fine thread. According to the different use occasions and functions, it can be divided into fastening thread, pipe thread, transmission thread, special thread, etc. Among the cylindrical threads, the triangular thread has good self-locking performance. It is divided into two kinds of coarse teeth and fine teeth. Generally, coarse thread is used for connection. The fine teeth have small pitch, small rising angle and better self-locking performance. They are commonly used in thin-walled tubes with small parts, such as vibration or variable load connections and fine adjustment devices.

Pipe thread is used for tight connection of pipe fittings. The rectangular thread has high efficiency, but it is often replaced by trapezoidal thread because it is not easy to grind and it is difficult to screw in and center the internal and external threads. The working edge of the serrated thread is close to the rectangular straight edge, which is mostly used to bear the unidirectional axial force.

The taper thread is triangular in shape, which mainly depends on the deformation of the thread to ensure the tightness of the thread pair. It is mostly used for pipe fittings. According to the tightness, it can be divided into sealing thread and non sealing thread.

Processing method of thread

(1) The method of directly machining thread with mould

(2) The processing method of forming and rolling die to produce plastic deformation of workpiece to obtain thread. The advantages of thread rolling in thread rolling machine are: the surface roughness is less than turning, milling and grinding; the surface of thread after rolling can improve the strength and hardness due to cold work hardening; the material utilization rate is high; the productivity is doubled than that of cutting, and it is easy to realize automation; Rolling die has a long life. However, the hardness of the workpiece material is not more than hrc40, the accuracy of the blank size is required to be high, the accuracy and hardness of the rolling die are also required to be high, so it is difficult to manufacture the die, and it is not suitable for the thread with asymmetric rolling Profile. According to the different rolling die, thread rolling can be divided into two types: thread rolling and thread rolling. The two thread rolling plates with thread profile are staggered by 1 / 2 pitch, and the static plate is fixed, and the moving plate moves in a reciprocating straight line parallel to the static plate. When the workpiece is sent between the two plates, the moving plate moves forward to rub and press the workpiece, making its surface plastic deformation and forming a thread.

There are three kinds of rolling: radial rolling, tangential rolling and rolling head rolling.

Radial thread rolling: two (or three) thread shaped thread rolling wheels are installed on mutually parallel shafts, the workpiece is placed on the support between the two wheels, and the two wheels rotate at the same speed in the same direction, one of which is also used for radial feed movement. The workpiece is driven by the rolling wheel to rotate, and the surface is extruded radially to form a thread. Similar rolling method can also be used for some screws with low precision requirements.

Tangential thread rolling: also known as planetary thread rolling. The rolling tool consists of a rotating central thread rolling wheel and three fixed arc-shaped thread plates. During rolling, the workpiece can be fed continuously, so the productivity is higher than that of thread rubbing and radial rolling.

Thread rolling head: it is carried out on an automatic lathe and is generally used to process the short thread on the workpiece. In the rolling head, there are 3-4 rolling rollers evenly distributed around the workpiece. When rolling, the workpiece rotates, and the rolling head feeds axially to roll the workpiece out of the thread.

Methods of machining the thread on the workpiece with finishing tools.

Thread milling: on the thread milling machine, use the disc milling cutter or comb milling cutter for milling. Disc milling cutter is mainly used for milling trapezoid external thread of screw rod, worm and other workpieces. Comb milling cutter is used for milling internal and external common thread and taper thread. Because the length of its working part is longer than the length of the thread to be processed by multi edge milling cutter, the workpiece can be processed only by rotating 1.25 ~ 1.5 revolutions, with high productivity. The pitch accuracy of thread milling can reach 8-9 grades, and the surface roughness is r5-0.63 μ M. This method is suitable for mass production of general precision thread workpiece or rough machining before grinding.

Today, the machining center with advanced technology has become an irreplaceable tool for all production enterprises. Therefore, more and more thread machining is carried out by milling, with high efficiency, high step simplification and high precision, thus bringing greater benefits to enterprises. In order to meet this demand, many companies are born on demand. For some special needs of the thread to provide professional programs.

Thread grinding: it is mainly used to process the precise thread of the hardened workpiece on the thread grinder. According to the different cross-section shape of the grinding wheel, it can be divided into two kinds: single line grinding wheel and multi line grinding wheel. The pitch accuracy of single line grinding wheel is 5-6 grade, and the surface roughness is r1.25-0.08 μ m, so it is convenient for grinding wheel dressing.

This method is suitable for grinding precision screw, thread gauge, worm, small batch of thread workpiece and precision hob. There are two kinds of grinding methods: longitudinal grinding and cut in grinding. The width of the grinding wheel with longitudinal grinding method is less than the length of the thread to be grinded, and the thread can be grinded to the final size after the grinding wheel moves longitudinally once or several times. The width of the grinding wheel of the cut in grinding method is larger than the length of the thread to be grinded. The grinding wheel cuts into the surface of the workpiece radially, and the workpiece can be grinded after turning about 1.25 revolutions. The productivity is higher, but the precision is slightly lower, and the dressing of the grinding wheel is more complex. The cut in grinding method is suitable for shoveling large quantities of taps and grinding some fastening threads.

Thread grinding: the nut type or screw type thread grinding tool is made of soft materials such as cast iron. The parts on the workpiece where the processed thread has pitch error are grinded by forward and reverse rotation to improve the pitch accuracy. The hardened internal thread is usually eliminated by grinding to improve the accuracy.

Tapping and threading: tapping is to use a certain torque to screw the tap into the pre drilled bottom hole on the workpiece to process the internal thread. Threading is to cut the external thread on the bar (or tube) workpiece with a die. The machining accuracy of tapping or threading depends on the accuracy of tap or die. Although there are many ways to process internal and external threads, small-diameter internal threads can only be processed by taps. Tapping and threading can be done by hand or by lathe, drilling machine, tapping machine and threading machine.

Notes on Turning Thread: considering the expansion of thread processing profile, the large diameter of external thread (nominal diameter d) should be turned 0.2-0.4mm (about 0.13p) smaller than the basic size, to ensure that there is a width of 0.125p (P is pitch) at the top of the thread after turning, and to ensure that the diameter of the bottom hole is – P when boring the bottom hole of internal thread..

Thread seal: any plane can’t be in close contact with each other. It needs leak proof seal. The traditional method is to use rubber, asbestos, metal and other gasket, but it will leak soon due to aging or corrosion. The solid gasket is replaced by anaerobic adhesive, which can realize close contact after curing and make the sealing more durable. Metley super lubricant is a kind of special inert material with many uses. It is used for sealing of threaded pipe joint and plug, sealing of flange mating surface, sealing of mechanical box mating surface and so on. It has good leak proof effect.