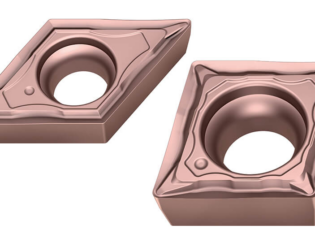

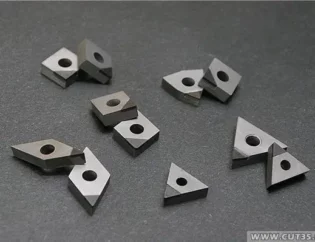

Carbide rods, due to their special properties of wear resistance, high hardness, excellent fracture toughness, and compressive strength, have been widely used in various fields such as metal processing, electronics industry, wood processing, aerospace industry, and medicine. They are ideal preliminary materials for manufacturing printed circuit board micro-drills, milling cutters, reamers, step tools, long rod tools, taps, and dot matrix printer needles. With the development of technology, the demand for carbide rods is increasing, and forming techniques have evolved from traditional processes such as cold isostatic pressing and die pressing to more modern and economical extrusion molding processes, resulting in better quality and a wider variety of products.

Sintering of carbide is a crucial step in the production of carbide. During the pressing process...

There are mainly two types of 3D printing technologies currently applied in tool manufacturing. One...

Aluminum alloy is a general term for alloys with aluminum as the base. The main...

What is carbide? carbide is an alloy material made through powder metallurgy process, consisting of hard...

Carbide heat treatment is a critical process that plays a crucial role in enhancing the...

The knowledge of carbide grade identification will be shared in this article.Carbide is renowned for...

Mining carbide need to be able to drill rapidly under high-power impact conditions while minimizing...

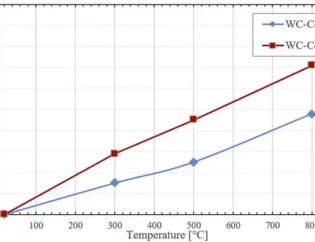

Coarse-grain WC powder possesses special properties and specific uses, especially high-temperature coarse-grain WC, which boasts...

Hyper carbide = hyper alloy + cemented carbide It is well known that there are...

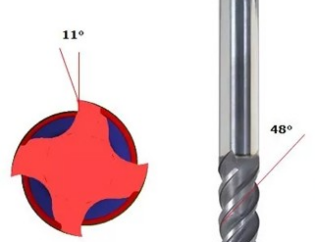

What milling cutter should be used for processing stainless steel? This is a question encountered...

The processed product is a bevel gear with 16 φ17 through-holes, made of sticky metal...

To discuss the problem of fatigue and fracture of cemented carbides, we must first understand...

This is an overview of the most common single-tool wear failures in cutting tools. These...

In machining process, the formation and evacuation of chips are crucial as they ensure the...

Hard turning (turning instead of grinding) refers to the process of using turning methods for...

With its high strength, good mechanical properties, and strong corrosion resistance, titanium alloy is increasingly...

Machining centers are generally divided into two parts: machine tool (mechanical part) and control system...

As we know, traditional turning machining involves a stationary tool and a rotating workpiece, while...

Causes of Milling Cutter Wear Milling cutter wear is primarily attributed to two main categories,...

carbide valves are widely needed in demanding conditions such as powder transport, wear resistance becomes a...

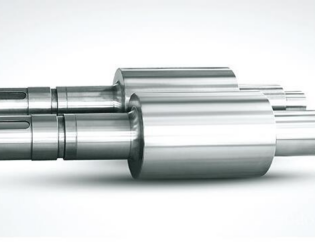

Carbide rolls are widely used in the production of bars, wires, threaded steel, seamless steel...

There are many types of specialized presses for diamond synthesis, and they can be classified...

Toothed wheel drill bit is an important tool widely used in the extraction of mineral...

People believe that screws are directly pressed out of the cold heading die. However, strictly...

Shield tunneling cutter are the key supporting tools for tunneling machines, and their performance and service...

Cutting parameters are not only important parameters that must be determined before adjusting the machine...

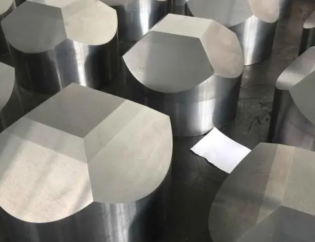

Cemented carbide anvils are essential consumables within synthetic presses, and synthetic presses are the core...

In the manufacturing industry, we often encounter a very small component – the nozzle. Despite...

The cylinder head is one of the crucial components of an engine, and it is...

MEETYOU CARBIDE produces a wide range of excellent tungsten carbide products (especially carbide rods, carbide...

MECÂNICA 2018 MECÂNICA MANUFACTURING EXPERIENCE April 24-27 2018 Booth: G114a Expo Center Norte – SP...

Keep up-to-date

Please enter your name.

Please enter a valid email address.

Something went wrong. Please check your entries and try again.