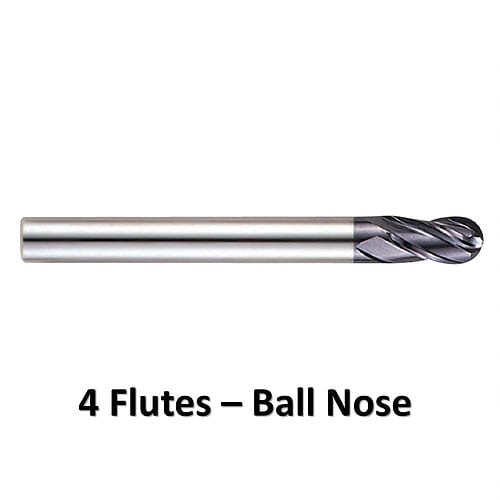

MG Series Solid Carbide End mills for General Use, 4 Flutes, Ball Nose, Metric

Suitable for Steel, Cast Iron and General use

Choosing

The Right Tool

When choosing the right carbide end mills for your applications, there are several factors to consider. These include the critical angles (end cutting edge angle, axial relief angle, radial relief angle, and radial rake angle) and length and finish of the flutes. We offer different series of carbide end mills for your most suitable application.

|

|

|

|

|

|

| MD | General Economy | Below HRC45 | HRC50 | AlTiN-based | grey |

| MG | General Purpose | Below HRC45 | HRC50 | AlTiN-based | grey |

| MP | High hardness | Below HRC55 | HRC60 | AlCrN-based | light grey |

| MH | Extremely High Hardness | Below HRC60 | HRC65 | AlTiN/TiSiXN | bronze |

| MC | Extremely Economy | Below HRC50 | HRC50 | TiSiN | bronze |

| SUS | Stainless Steel | Finishing | Roughing | AlCrN/SiN | blue grey |

| AL | Aluminum | Aluminum | Aluminum | None | None |

Also, we can provide cut-to-length h6 polished carbide rods(cutting tool blanks) for end mills manufacturing.

Whether you know exactly what type of carbide end mill is required or need to discuss the options with an expert, we are here to help.

Our

Advantages

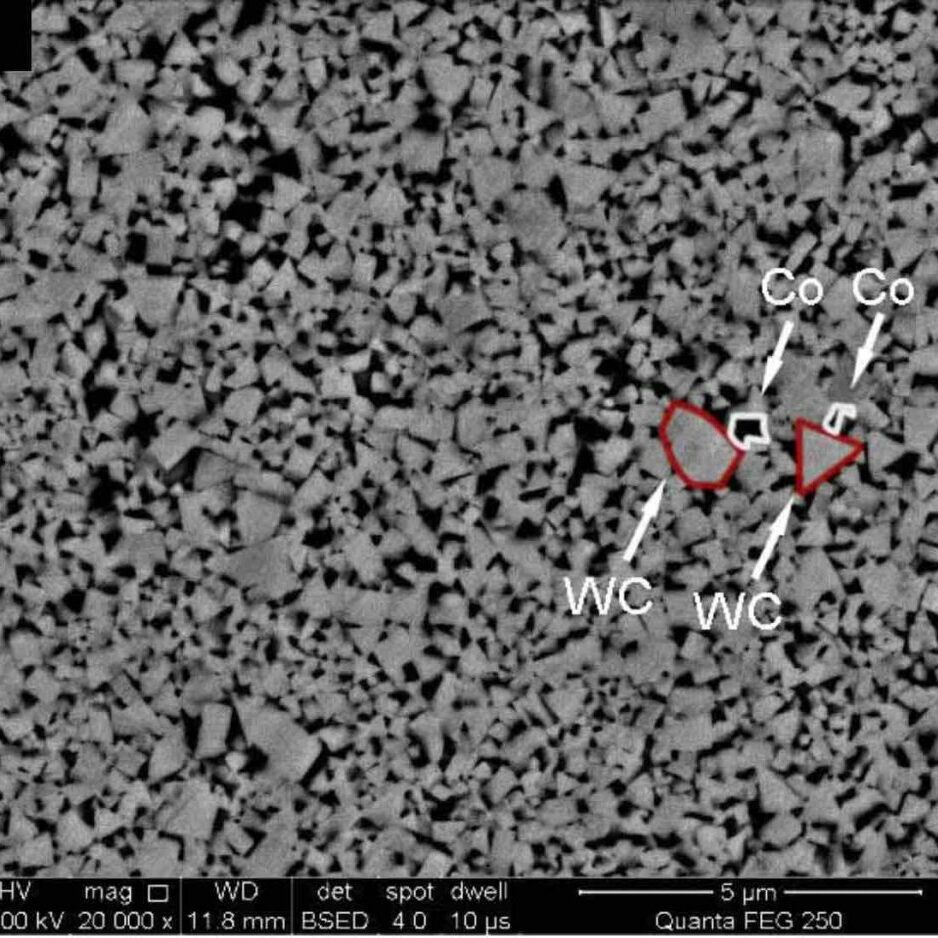

Quality Material

Thanks to our premium quality carbide rod made from Germany H.C.Starck powder, we take the first lead over others.

Advanced CNC Grinders

Advanced CNC five-axis CNC grinders from ANCA, Rollmantic and Walter to ensure the accuracy.

Nano Coatings

Multilayered nano PVD coatings are applied to strengthen our end mills cutting competence.

Ready to find out more?

Email us today for more information!

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.