Semente karbür uçların işlenmesinde kumlama temizleme işlemi

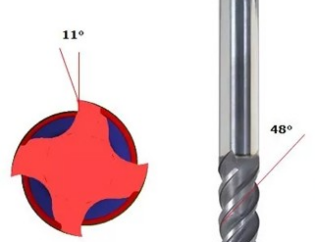

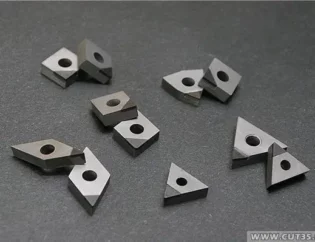

Sektörün hızlı gelişimi ile modern yüksek hızlı işleme ve otomatik takım tezgahları takım performansı ve stabilitesi için daha yüksek gereksinimler ortaya koymaktadır. Çimentolu karbür, yüksek sertliği, aşınma direnci, mukavemeti ve tokluğu, ısı direnci ve korozyon direnci nedeniyle bıçakların üretiminde yaygın olarak kullanılmaktadır. Karbür uçlar karmaşık üretim süreçlerine sahiptir ve kumlama işlemindeki kritik bir süreç, bıçak kaplamalarının yapışma mukavemetini ve görünümünü doğrudan etkiler. Hizmet ömrü belirleyici bir rol oynar.

Kumlama işlemi

Kumlama kuru kumlama ve ıslak kumlama olarak ikiye ayrılır. Kuru kumlama, kum malzemesinin doğrudan iş parçasının yüzeyine püskürtülmesi ile oluşturulan basınçlı hava ile oluşturulan bir çeşit temizleme yöntemidir; ıslak kumlama, kum ve su karışımını iş parçasının yüzeyine yönlendiren basınçlı hava tarafından oluşturulan bir temizlik türüdür. İşleme yöntemleri.

Genellikle, sıradan bıçak (ile) sinterlemeden sonra kuru kumlama ile temizlenir ve CNC bıçak (ile) kaplama ıslak kumlama ile temizlenir. Sıradan bıçak sinterlendikten sonra, yüzey düzensizdir ve safsızlıklara sahiptir. Genellikle kaba beyaz korindon ile temizlenir. Kumlamadan sonra, kirleri etkili bir şekilde giderebilir ve düzgün bir yüzey elde edebilir. Islak kumlama temizliği en çevre dostu kumlama temizliği olarak bilinir. Her türlü karbür aletini işlemek için uygundur, tozsuzdur. Bir çeşit PVD ve CVD bıçak kaplama teknolojisidir. Islak kumlama işlemi yurt dışındadır. Semente karbür endüstrisinde yaygın olarak kullanılmaktadır. Karbür uçlar üzerine ıslak kumlama uygulaması üç açıdan somutlaştırılmıştır:

1. bıçak (ile) yüzey pürüzlendirme temizleme

Islak kumlama, çimentolu karbür uçların yüzeyini kaplamadan önce eşit olarak pürüzlendirebilir. Aşındırıcılar genellikle kaba beyaz korindondan yapılır. Temizlikten sonra, istenen pürüzlülük değeri elde edilebilir ve malzemenin yüzeyi üzerindeki artık basınç gerilimi azaltılabilir. Malzemenin yüzeyindeki Co içeriğinin azaltılması, malzemenin karbür fazının çıkarılması  çimentolu karbür kesici ucun bıçağı ve ıslak patlatma ön işleminden sonra PVD ve CVD tortulu kaplama, kaplama ve substrat arayüzü arasındaki bağlanma kuvvetini geliştirir. Tabakanın aşınma direnci ve bıçağın kullanım ömrü önemli ölçüde artırılır ve kaplanmış bıçağın (ile) kesme performansı iyileştirilir.

çimentolu karbür kesici ucun bıçağı ve ıslak patlatma ön işleminden sonra PVD ve CVD tortulu kaplama, kaplama ve substrat arayüzü arasındaki bağlanma kuvvetini geliştirir. Tabakanın aşınma direnci ve bıçağın kullanım ömrü önemli ölçüde artırılır ve kaplanmış bıçağın (ile) kesme performansı iyileştirilir.

2. bıçak (ile) kesme kenarı pasivasyon temizleme

Bıçak kesme teknolojisi, takım ömrünü uzatmak ve takım tüketimini azaltmak için etkili önlemlerden biridir. Ekonomisi ve teknik iyileştirme esastır, bu da Çin'de kesme işleme seviyesinin daha da geliştirilmesini sağlar ve yabancı takımların kesme performansını azaltır. boşluk. CVD kaplı kesici uçlar (ile), kaplama öncesinde aletin kesici kenarının pasifleştirilmesini gerektirir. CNC takım tezgahlarının kesici kenarları ve yurt dışından ithal edilen üretim hatları pasifleştirildi. Pratik araştırma, takım kenarı pasivasyonunun takım ömrünü etkili bir şekilde 200% veya daha fazla uzatabildiğini, aracın maliyetini büyük ölçüde azalttığını ve kullanıcıya büyük ekonomik faydalar sağlayabildiğini göstermektedir.

Geleneksel pasivasyon işlemi genellikle bıçağı bir kesici kenarı (ile) keskinleştirmek için normal bir taşlama tekerleği veya bir elmas taşlama tekerleği kullanır ve bilemeden sonraki kenarın farklı derecelerde mikroskopik bir çentiği vardır, yani bir mikro talaş ve çentik . Birincisi çıplak gözle ve sıradan bir büyüteçle gözlemlenebilir. İkincisi, genellikle 0,01 mm ila 0,05 mm arasında değişen 100 kez (0,010 mm çizgi ile) mikroskopik boşluk ve 0,1 mm veya daha fazla ağır vakalar ile gözlenebilir. Aletin kesici kenarındaki mikro çentik, kesme işlemi sırasında kolayca aşınır ve bu da aletin aşınmasını ve hasarı hızlandırır.

Islak kumlama pasivasyonu temizliği genellikle başarılı bir şekilde test edilmiş ve kullanımda olan ince beyaz kaynaşmış alümina ile yapılır. Islak patlatma pasivasyonunun amacı, keskinleştirmeden sonra aletin kesme kenarının mikro çentiğinin kusurunu çözmektir, bu da ön değeri azaltan veya ortadan kaldıran, kenar gücünü etkili bir şekilde iyileştiren, takım ömrünü ve kesme stabilitesini iyileştiren süreci. Pasifleştirilmiş bıçak kaplamanın kalitesini iyileştirir, kenar değerini azaltır ve kaplamanın sağlamlığını ve uzun ömürlülüğünü iyileştirir. Takım malzemesi, takım geometrisi, takım yapısı ve kesme miktarı optimizasyonuna ek olarak takım kesme performansını ve takım ömrünü etkileyen birçok faktör vardır.

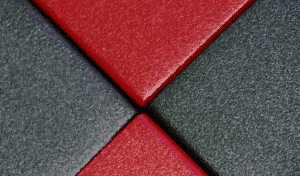

3. bıçak (ile) kaplama parlatma

Semente karbür insert (ile) kaplamanın ardından, kaplamanın yüzeyi donuk ve görünüş normaldir. Islak kumlama ile temizlenir ve kaplamanın yüzeyini daha da inceltmek için ince beyaz korindon veya cam boncuklarla temizlenir, yüzeye metalik bir parlaklık verir, güzel bir cam etkisi elde edilir ve ürün görünümünü iyileştirir.