1.Development of Cryogenic Treatment Process Cryogenic treatment usually adopts liquid nitrogen cooling, which can cool...

Edge radius processing is an indispensable process after fine grinding of CNC tools and before coating....

Etching is a technology that uses chemical strong acid corrosion, mechanical polishing or electrochemical electrolysis...

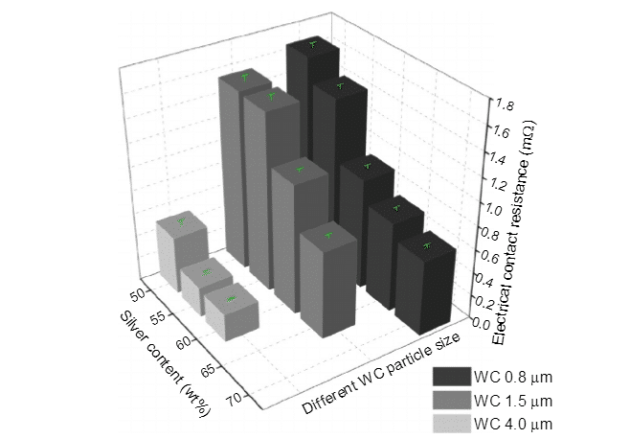

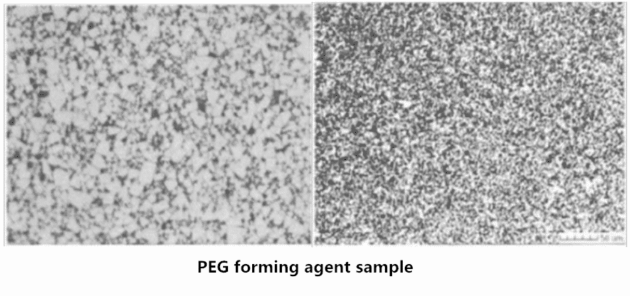

Cemented carbide is a kind of cemented carbide which is made by powder metallurgy process...

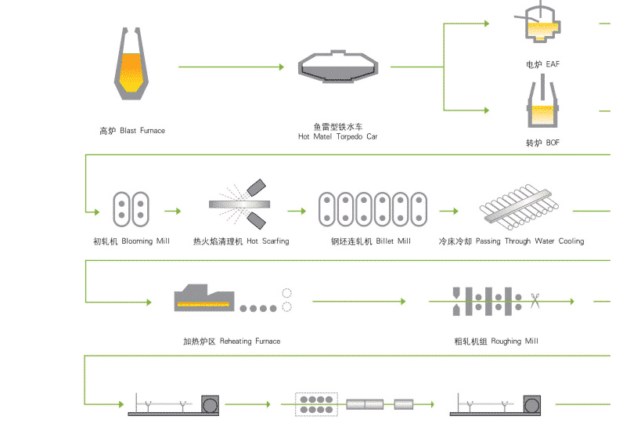

introductionSteel is quenched by heating the steel to a temperature above the critical temperature Ac3...

First, the molecular beam epitaxial profileIn the ultra-high vacuum environment, with a certain thermal energy...

1, Review of Organic Halide Perovskite – related Photoelectric PropertiesFigure 1 Spectral position and PL...

First, the development of a brief historyThe first stage: 1945 to 1951, the invention of...

First, the basic concept of particle size analysis(1) particles: with a certain size and shape...

【introduction】The construction of flexible electronic devices with certain functions and structures provides a variety of...