Nó là một thùng nghiền dùng để nghiền các vật liệu dạng hạt thành bột bằng cách rung. Khi làm việc, đặt bát nghiền vào khe của máy nghiền mẫu hoặc máy nghiền rung. Thông qua độ rung lệch tâm của máy, vật liệu có thể đạt tới mẫu lưới 60-300, sau đó được sử dụng để thử nghiệm. Đây là phương pháp nghiền được sử dụng rộng rãi nhất để chuẩn bị mẫu vật liệu trong phòng thí nghiệm.

Grinding bowl is the main implement of sample grinding. Grinding bowl materials mainly include zirconia ceramics, carbon steel, high manganese steel, chromium steel, wear-resistant alloy, tungsten carbide, agate, Teflon, etc. The grinding bowl can be selected according to different materials.

zirconia ceramic grinding bowl

Introduction of zirconia ceramic grinding bowl: Zirconia is a kind of high-purity ultra-fine zirconia powder produced by advanced liquid phase coprecipitation method, and then sintered to form zirconia ceramics. Relying on advanced technology and using advanced equipment, various zirconia grinding media, zirconia ceramic structural parts, color zirconia ceramics and zirconia ceramics can be manufactured, High cleanliness is widely used in chemical, automotive, electronics, mining equipment, machinery manufacturing, medical devices, electronic ceramics, refractories, aerospace, jewelry and other industries.

Characteristics of zirconia ceramic grinding bowl:

1. Very low wear (PPM) can prevent material pollution.

2. Suitable for high viscosity, wet grinding and dispersion.

3. High grinding efficiency.

4. Long service life and low comprehensive operation cost.

5. It has high wear resistance, corrosion resistance, impact resistance and high temperature resistance.

6. High surface finish and self lubrication.

7. Light weight, high speed limit, low noise, electrical insulation, stable size at high temperature, small starting torque.

Properties of zirconia material:

component WT% 94.8%ZrO25.2%Y2O3 density g/cm3 ≥6.0 hardness Kg/mm2 ≥1250 Bending strength MPa one thousand one hundred and fifty fracture toughness MPa.m1/2 ≥9 grain size υ m ≤0.5 Elastic modulus GPa two hundred Thermal conductivity w/(m.k) three Coefficient of thermal expansion X10-6M/℃(20-400℃) nine point six High purity materials are widely used in biological industry, electronic industry, microelectronics industry, semiconductor industry, battery material industry, aerospace industry, solar cells and optical glass and other high-tech fields. In the process of preparing these materials, the common mechanical crushing and sample preparation methods are easy to cause the secondary pollution of materials, especially the pollution of metal ions. Therefore, zirconia can effectively solve the problem of pollution, widely used.

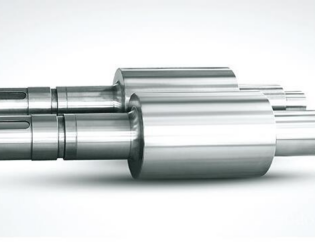

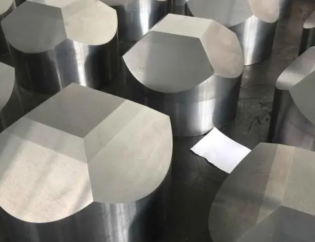

WC grinding bowl

The tungsten carbide grinding bowl is sintered from tungsten cobalt powder and then ground with diamond grinding wheel. Different from the cemented carbide cutter head material in machining, its material should not only have high hardness, high wear resistance, but also high impact resistance. To adapt to working conditions. Pure WC powder can’t be formed, so cobalt must be added for sintering. The higher the content of WC is, the higher the hardness of the grinding bowl is, but the strength decreases and becomes brittle. So choose the appropriate proportion. Although the grinding bowl of cemented carbide has high hardness and good wear resistance, it is not allowed to be smashed and knocked. Appropriate use methods can improve the service life of the grinding bowl. During charging, the samples should be evenly distributed in the middle of the solid core block, circular ring and bowl wall. In order to avoid unnecessary wear, please try to avoid the tungsten carbide grinding bowl rotating over the crusher. The WC grinding bowl is covered with steel to avoid bumping. The sealing ring is used to prevent the powder from escaping. Even if the grinding bowl itself is slightly worn and falls into the powder during the grinding process, it will not cause sample pollution. In order to avoid cross contamination among samples, it is recommended to use a tungsten carbide grinding bowl for each sample, chromium steel or manganese steel grinding bowl for coarse material crushing, and tungsten carbide grinding bowl for those requiring no iron pollution.

The quality is as follows: content: WC 85.5% Co14.5%; Hardness: 87.5 HRA; Density: 14.1g/cm3 bending strength: 2080mpa

Structure: the grinding bowl is inlaid structure.

Tungsten carbide grinding bowl; X-ray fluorescence spectrometer is famous for its fast and high precision. In particular, X-ray fluorescence spectrometer for powder sample preparation is widely used in the field of material composition analysis. The powder fineness required by X-ray fluorescence spectrometer is 200-400 mesh (0.074 mm) to avoid the error caused by powder particle effect. How to achieve the ideal grinding effect in the use of the machine, too long grinding time will cause the sample to stick and the grinding bowl temperature to rise significantly, too short time can not reach the grinding fineness, in order to get the best grinding effect, the user can adjust the grinding time according to the vibration frequency of the grinder. The pollution source on the surface of grinding bowl can not be ignored, so one or more waste samples (commonly known as pot brushing) should be produced as far as possible before formally crushing the sample. In order to be able to match with different types of sample making grinder, it can be customized ф 155、 ф 183、 ф 195 tungsten carbide grinding bowl with various dimensions.