顾名思义,超硬材料就是硬度极高的材料。一般来说,金刚石的硬度最高,莫氏硬度为10,CBN的硬度略低于金刚石。因此,超硬材料通常是指金刚石和CBN,或以这两种材料为主要成分制成的复合材料。

刚玉、碳化硅、硬质合金和高速钢这四种被用作“工业牙齿”的硬质材料,其硬度远低于金刚石和立方氮化硼。因此,超硬材料也被称为最坚硬、最锋利的“工业牙齿”或“材料之王”。

1. 钻石

与其他碳材料一样,金刚石的主要化学元素成分是碳。无论是天然钻石还是人造钻石 人造金刚石不论哪种钻石都会含有或多或少的杂质。金刚石一般含有氮杂质。根据金刚石晶体中氮含量的不同,金刚石可分为两类(I型金刚石和II型金刚石)。

近年来,碳材料是一种非常热门的材料。 21世纪也被称为“碳时代”。碳材料以其优异的性能被广泛应用于各个领域,特别是在国家战略性新兴产业,如石墨烯及碳纳米材料、碳纤维及其复合材料、金刚石碳基薄膜和传统碳材料(炭黑、多孔碳、石墨、特种石墨等)在锂电池、电容器、储能、光伏、半导体、光电显示、5G通讯、传感器、通用航空、未来交通、高端装备等领域具有广阔的应用前景

2、cBN

立方氮化硼(CBN) 是超硬材料的第二大品种。氮化硼的化学结构式为BN,由硼和氮组成。氮化硼有四种不同的晶体结构,主要是六方氮化硼(hBN)、立方氮化硼(CBN)、菱方氮化硼(RBN)和致密六方氮化硼(WBN)。 hBN和RBN中的氮和硼原子在SP2中杂化,而CBN和WBN中的氮和硼原子在SP3中杂化。

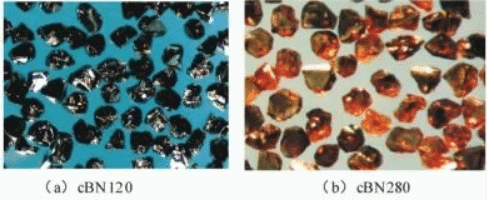

CBN的硬度略低于金刚石,晶体颜色与杂质的种类和数量有关。 CBN具有独特的光电特性。合成大尺寸、高质量的CBN单晶是功能器件应用的必然选择。然而,CBN晶体的大尺寸远不如金刚石成功。这可能是因为大颗粒CBN的合成条件比较严格,其应用还没有找到合适的领域。

超硬材料的应用

1、超硬材料产品

超硬材料及其制品和工具已广泛应用于工业。它们不仅解决了传统工具无法加工或难以加工的问题,而且显着提高了传统加工效率,显着降低了消耗和废物排放。

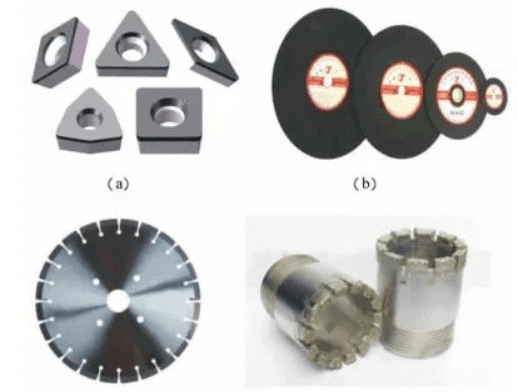

几种超硬材料产品和工具(A.刀片;B.砂轮;C.锯片;D.钻头)

超硬材料产品和工具的主要品种包括锯切工具、磨具(包括固结磨具、涂附磨具和松散磨具)、切削工具、钻孔工具、精加工工具、拉丝模具、其他工具和不同功能的零件。

2. 天然和人造钻石

(1) 天然金刚石

从天然钻石中提取的钻石称为天然钻石。天然钻石明亮、华丽、稀有、珍贵。它们被视为珍宝。有一则广告写着“一颗钻石永存,永恒”,这是中国妇女和儿童所熟知的。

天然钻石除了用作首饰外,更多地用于工业。金刚石的工业用途长期以来一直是利用其特殊的高硬度。切割玻璃的金刚石刀提醒我们,金刚石是用来为地质勘探和石油和煤炭开采准备钻头的。金刚石在高温下会被氧不同程度地氧化,特别是与铁的亲和性好,不适合黑色金属加工。

(2) 人造金刚石

人造金刚石,业内又称实验室合成金刚石或培育金刚石。大颗粒或单晶的人造钻石已被用来加工合成钻石首饰。人造钻石也是真正的钻石,其成分和结构与天然钻石相同。两者只能通过一种非常特殊的方式来区分。例如,在阴极发光仪器下,前者的生长织构是几何形的,后者是环形的。自2006年起,GIA等珠宝机构开始提供鉴定服务并颁发证书,主要是为了防止商家以低于天然钻石的价格出售合成钻石。过去,钻石行业的研究人员一直在寻找人造钻石的高效合成方法,但一直没有突破。两个主要障碍来自成本和生产因素。经过几十年的研究,静态催化剂条件下超高压高温法合成大金刚石单晶的技术已经成熟。我国在超高压高温法合成人造金刚石大单晶和微波等离子体CVD法合成人造金刚石的技术开发和应用方面取得了快速发展。人造钻石首饰已在市场上销售,并已初具规模。

三、CBN的主要应用

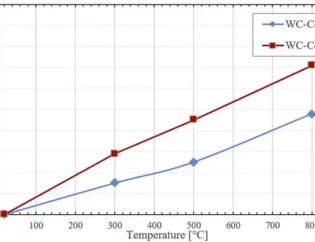

CBN与金刚石相比具有独特的优势,如高热稳定性和与铁族元素的化学惰性。

目前,CBN主要用于两个方面:一是制造磨具,二是制造多晶立方氮化硼作为工具材料。因此,CBN在加工黑色金属材料方面独树一帜,为硬、韧难加工的铁基材料提供了一种新的加工工具。

用作研磨材料。不仅可用于铁基材料的加工,也可用于有色金属材料的加工。

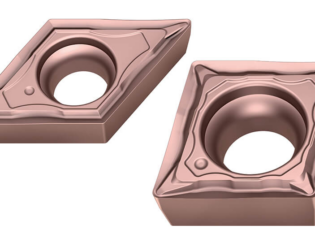

用作工具材料。多晶立方氮化硼一般用于刀具。 PCBN是由CBN单晶制备的微粉。它是通过添加碳化钛、钴和其他粘合剂,然后用六面顶压机在高压和高温下烧结而成。对黑色金属及其合金的加工特别有效,特别适用于高速切削和干切削。实现了以车代磨、以铣代磨,大大提高了生产效率。

用作功能材料。高导热CBN可应用于光电功能器件。

超硬材料是许多不同材料的小变种,但它是一种不可替代的材料,可能会逐渐取代其他一些材料。