您应该了解有关分模工具和分模操作的知识

分型是将刀片之类的工具直接插入到工件中,并切下一定长度的工件。通常用于从卡盘的杆上移出工件的精加工端。其他用途包括切割螺栓的头部。

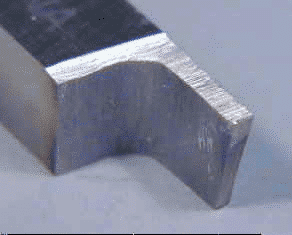

商业分割工具

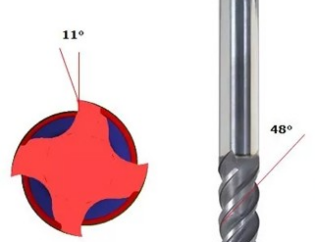

There are many kinds of commercial parting tools provided by tool suppliers, but most of them are too large to be used on 7×10.

This is problematic because the top of the parting tool must be centered. The 7×10 interest group described many attempts (including my own), including grinding, turning, and grinding, to remove 1 / 16 “from the bottom of the carriage, but with little success. The tool holder is quite hard metal.

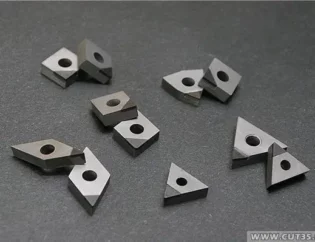

Even so, the gadget is tempting, because grinding a separation tool from a tool blank is painful – because so much metal has to be ground off – and the separation tool becomes dull and brittle. This tool and similar large tools use preformed tools. If you break the end, you just need to grind a new tip and continue. I haven’t done that yet, but the best solution is to use the high frequency 5 / 16 “parting tool, which may just make a custom tool holder of the right height.

This is another 1 / 2 “business separation tool. I plan to customize a knife rest for it one day.

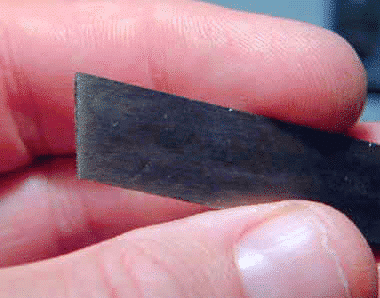

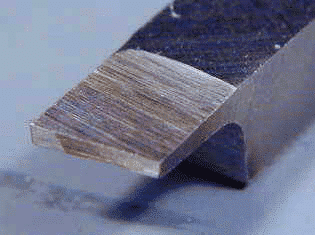

裁缝地面分离工具

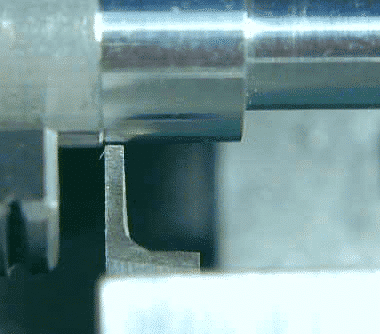

磨削自己的分离工具并不是很困难,但是要花费很长时间,并且会产生大量金属和磨屑,因为您必须从毛坯中移走相对大量的金属。这是一些家用地面工具的典型图片。请注意,该工具从顶部到底部逐渐变细(就像一个狭窄的梯形),从前面到后面逐渐变细,为切割头提供了安全性。刀具的顶部被磨掉了千分之几英寸,以使刀具的顶部边缘与车床中心线对齐。如果您的刀架的工具高度可调,则不必这样做。在工具边缘附近形成分型刀片可使工具在卡盘钳口附近工作。

夹紧工件

Separation always takes place close to the chuck jaws – no more than 1 / 2 “, preferably no more than 1 / 4”. Parting cutting exerts great tangential force on the workpiece. If the cutting is too far away from the chuck claw, the workpiece may be extruded from the chuck.

调整刀头

For parting cutting, the top of the tool should be exactly on the center line of the lathe, or no more than 0.005 “of the center line. If the tool is a little higher, it will tend to “climb” the workpiece; if it is a little lower, it will tend to dig in. The tip of the tool should be completely perpendicular to the workpiece.

速度和进给

确保丝杠 处于中间位置,因此丝杠不会移动。现在,将半螺母锁定在接合位置,以防止刀架在切割过程中移动。分型切割应低速进行;例如200-300 RPM甚至更慢。

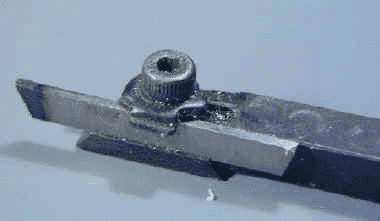

切入

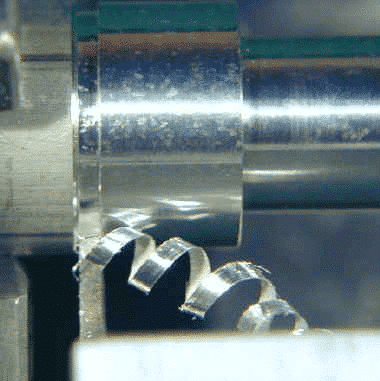

使工具的尖端刚好超出工件表面,然后打开车床。缓慢推进横向滑动曲柄,直到工具开始切入金属。继续前进,直到稳定的切屑从工件上卷曲下来,然后尝试保持该切削速度。

It’s a good idea to use cutting oil for a parting cut and you will find that the heat generated will most likely cause a fair amount of smoke as the cutting oil burns off. Avoid breathing this smoke cause I’m sure it’s not good for your lungs, although no proof says it has bad effect . A small fan to disperse it may be a good addition to your workbench.Chatter

Parting often causes ‘chatter’. If you have never heard this sound, you will easily recognize it when you first do. It is a pulsing, whining vibration that can shake the whole lathe and even cause it to move around on the workbench if is not bolted down. You can stop chatter quickly by backing off the pressure on the tool. The trick is to find the right speed at which to advance the tool with minimal chatter.

这里有一些技巧可以最大程度地减少chat不休:

- 工具提示应该非常锋利

- 工具顶部应在车床中心线上

- 工具应垂直于工件

- 交叉滑动和复合物上的吊臂应该紧贴

- 马鞍应该紧贴方式

- 使用马车锁将马鞍锁定到方式

- 使用切削液

- 保持横移稳定前进

完成分型切割

继续前进直至其到达工件中心。靠近时,工件会被一根细细的金属杆悬挂。

注意:如果工件从卡盘伸出的直径超过其直径的几倍,则工件的末端可能会开始以危险的弧度摆动。当您靠近中心时,可能需要放慢卡盘速度以确保物品安全。如果您发现工件开始摆动,请停止车床并用手来回移动工件以使其脱离。

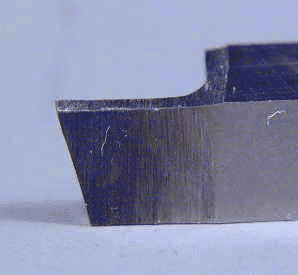

切下的工件末端通常会具有相当粗糙的光洁度,并且从末端会突出一些金属杆。

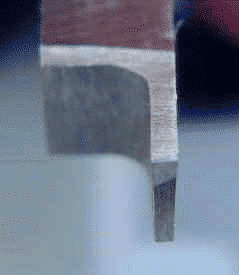

One limitation of parting tools is the diameter of the work that can be parted. The tool illustrated here is a little under 3/8″ long and can part off work up to 3/4″ in diameter. In the previous picture you can see that the edge of the work is rounded because it was rubbing up against the shoulder of the cutting tool. If you make the tip of the tool much longer than about 1/2″ it starts to get too limber and will easily break off. So on a small lathe like this, the largest diameter work that you can part off is probably around 1″. To cut off bigger work, you can use a small hacksaw while turning the work at low speed in the lathe. Even better, if you have a metal-cutting bandsaw, use it to cut off the work. I nearly always use the bandsaw for work larger than 1/2″ diameter.

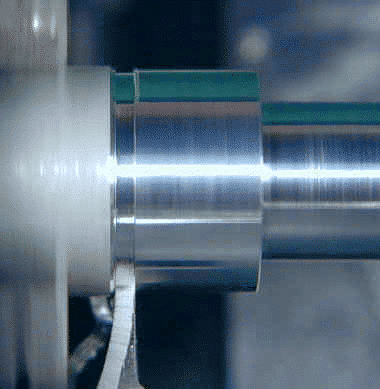

最后一步,将其安装在卡盘上并进行切面处理以清理末端。该步骤的一个问题是卡盘钳口会损坏成品工件。如果仔细查看下一张图片,您实际上可以看到卡盘钳口的印记。为避免这种情况,您可以在夹紧工件之前,先将其包裹在薄纸条或类似的保护材料中。