硬质合金刀片加工中的喷砂清理工艺

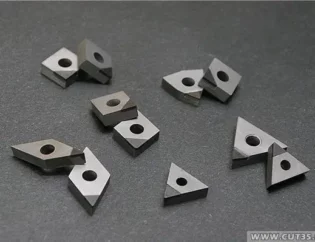

随着行业的快速发展,现代高速加工和自动化机床对刀具性能和稳定性提出了更高的要求。硬质合金由于其高硬度,耐磨性,强度和韧性,耐热性和耐腐蚀性而被广泛用于叶片的生产。硬质合金刀片的生产过程很复杂,喷砂过程中的关键过程直接影响着叶片涂层的附着强度和外观。使用寿命起着决定性的作用。

喷砂工艺

喷砂分为干式喷砂清理和湿式喷砂清理。干喷清理是一种通过压缩空气直接将砂料喷射到工件表面上而形成的清理方法;湿喷清理是通过压缩空气将沙子和水的混合物驱动到工件表面而形成的一种清理。加工方法。

通常,在烧结之后通过干喷清理来清洁普通刀片(带有),而通过湿喷清理来清洁CNC刀片(带有)涂层。普通刀片烧结后,表面不平坦且有杂质。通常用粗糙的白色刚玉清洗。喷砂后,可以有效去除杂质并获得均匀的表面。湿喷砂清理被称为最环保的喷砂清理。适用于加工各种硬质合金刀具,无粉尘。它是一种PVD和CVD刀片涂层技术。湿喷清理工艺在国外。已被广泛应用于硬质合金行业。湿喷清理在硬质合金刀片上的应用体现在三个方面:

1.刀片(带)表面粗糙清洁

湿喷清理可使涂层前的硬质合金刀片表面均匀粗糙。磨料通常由粗糙的白色刚玉制成。清洁后,可以获得所需的粗糙度值,并且可以减少材料表面上的残余压应力。减少材料表面的Co含量,去除材料表面的碳化物相  硬质合金刀片的刀片,湿喷砂预处理后的PVD和CVD沉积涂层改善了涂层与基材界面之间的结合力。大大提高了涂层的耐磨性和刀片的使用寿命,并改善了带涂层刀片的切割性能。

硬质合金刀片的刀片,湿喷砂预处理后的PVD和CVD沉积涂层改善了涂层与基材界面之间的结合力。大大提高了涂层的耐磨性和刀片的使用寿命,并改善了带涂层刀片的切割性能。

2.刀片(带)尖端钝化清洁

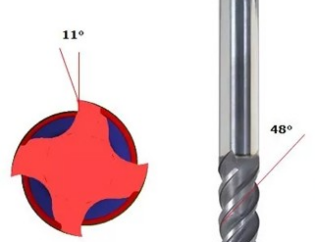

刀片切割技术是延长刀具寿命并减少刀具消耗的有效措施之一。其经济性和技术进步至关重要,这进一步促进了中国切削加工水平的提高,并降低了国外刀具的切削性能。间隙。 CVD涂层的刀片(带有)需要在涂层之前钝化刀具的切削刃。从国外进口的数控机床和生产线的尖端已全部钝化。实践研究表明,刀具边缘钝化可以有效地将刀具寿命延长到200%以上,从而大大降低了刀具成本,为用户带来了巨大的经济效益。

常规的钝化工艺通常使用普通砂轮或金刚石砂轮来打磨刀片(带有)切削刃,并且在磨削后的边缘具有不同程度的微观缺口,即微碎屑和切缝。 。前者可以用肉眼和普通的放大镜观察。后者可以用100倍的显微镜观察(0.010毫米线),显微镜间隙通常在0.01毫米至0.05毫米之间,严重的情况下可达0.1毫米或更大。刀具切削刃的微凹口在切削过程中很容易扩大,从而加速了刀具的磨损和损坏。

湿喷砂钝化清洁通常使用白色熔融氧化铝进行,该氧化铝已成功测试并投入使用。湿式喷砂钝化的目的是解决磨刃后刀具切削刃的微凹口缺陷,减少或消除刀锋值,有效提高刃口强度,提高刀具寿命和切削稳定性处理。钝化的刀片提高了涂层的质量,降低了边缘值,并提高了涂层的坚固性和寿命。除刀具材料,刀具几何形状,刀具结构和切削量优化外,还有许多因素会影响刀具的切削性能和寿命。

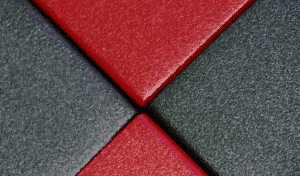

3.刀片(带)涂层抛光

硬质合金刀片(带)涂层后,涂层表面变钝,外观正常。用湿喷砂清洗,再用细的白色刚玉或玻璃珠清洗,以进一步改善涂层表面,使表面具有金属光泽,达到美丽的上光效果并改善产品外观。