随着越来越多的金属零件制造商了解粉末冶金的优势,他们开始寻找新的和改进的方法来使用这种工艺。同时,他们熟悉和熟悉当前的锻造工艺。

但是,如果您可以将这两种技术结合起来,生产出性能优于传统粉末金属 (PM) 的锻造金属零件,那会怎样呢?这实际上是可能的。其实它有一个名字:粉末金属锻造。

Let’s understand the use of powder metallurgy forging and traditional powder metallurgy and traditional forging. As a reward, we will show a new alternative that is even more efficient than PM forging…

什么是粉末金属锻造?

粉末金属锻造是粉末冶金和锻造的结合。也称为粉末锻造,这种金属锻造使用粉末材料,因为它们在以下方面具有优势:

1 成型能力

2 减少生产具有某些潜在独特优势的最终部件的工艺步骤数量,例如连杆端盖的断裂和开裂

3 最小浪费

其余部分被锻造用于生产比传统粉末金属部件更耐用的高强度部件。

当原料粉末被压实然后烧结时,锻造粉末金属的过程就开始了。烧结后,但当零件仍处于高温(1800°F以上)时,机械手立即抓取零件并将其转移到锻模上。

If real estate is related to “location”, then the powder metal forging process is related to “density”. The purpose is to make PM parts as close to full density as possible. This will provide you with higher performance and higher mechanical properties. If operated properly, the porosity of parts can be eliminated by more than 99%.

传统粉末金属锻造件 VS 烧结件

确定是否使用粉末锻造需要了解哪些金属可以锻造,哪些质量对项目最重要。粉末冶金甚至可以以比锻造更高的生产率生产复杂零件。

粉末金属材料可以进行常规的烧结处理,以提高抗拉强度和弯曲疲劳强度。由于粉末冶金固有的净成形能力,成形比冲压加工更容易。

然而,当强度是绝对必要的,而 PM 还不够时,金属锻造工艺可能是更好的选择。通过粉末锻造,形状复杂性好,但粉末冶金还是要好得多。

However, there are still many examples of powder metallurgy forging and impressive results have been achieved. Take the connecting rod as an example. It has a unique shape. The pin end enters the interior of the piston, and the crank end is a large hole at the bottom, which is molded on the high shaft. With powder metallurgy forging, you can actually make these holes during the forging operation, thus reducing material waste and not requiring too much “flash” to fill the blockage or precision forging indentation.

You can use the traditional forging method to forge 1.2 pounds of raw materials, but with the powder metallurgy forging method, there may be only 1.02 pounds of low-cost iron copper carbon powder. This means reducing secondary processing – giving you a lead in the game.

It’s even better: ultra high temperature as an alternative to powder forging

将粉末冶金与锻造相结合听起来像是双赢,对吧?这绝对是真的.. 如果您的预算不是问题。

为了制造锻造金属产品,制造商需要:

1A压实机

2A特别设计的烧结炉

3A锻压机

4 其他设备

让所有这些机器工作起来非常昂贵,而且成本将直接落在你的腿上。

传统粉末冶金可能无法提供您想要的性能水平,但传统锻造可能非常昂贵。那么,我们能为介于两者之间和边缘的人们做些什么呢?

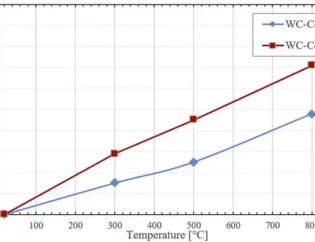

超高温烧结可以提高粉末金属零件的强度和其他性能,使您接近粉末冶金锻造的位置。我们将超高温烧结定义为在接近 2500°F 的温度下加热铁粉。

这是一种折衷方案,实际上可能给您带来的不仅仅是部分的总和。传统粉末冶金可提供50-70%的粉末冶金锻造性能。超高温烧结可提供80-90%的粉末冶金锻造。

通过使用超高温烧结,您可以保留金属粉末提供的更多固有尺寸精度,但您也可以提供接近粉末冶金锻造能力的机械性能。

One always popular side effect is that using a strict PM process may make material use more efficient. When forging connecting rods, the manufacturer must remove the resulting “flash”. Ultra high temperature sintering can produce a connecting rod to make your strength requirements without manual finishing, which will make it ready for field action.