Metal processing is inseparable from the blade. A good blade must have high wear resistance, long tool life, high metal removal rate and high reliability. It is even required to have high performance in dry cutting or wet cutting under severe conditions (such as complex cutting and deep cavity), so as to ensure small tolerance of workpiece size and excellent surface quality. Today, let’s take a look at how the leader of the blade industry produces blades

How to make blade tolerance accurate

A typical blade is made of 80% tungsten carbide and metal matrix. The function of metal matrix is to bond hard cemented carbide powder together, of which cobalt is the most common. The process of producing blades is very complex. It takes more than two days to complete, and there will be a lot of challenges. In addition to absolute precision and reliability, cleanliness is a prerequisite. The whole process must be well guaranteed without any carelessness.

第一步是确保每种特定粉末的组成比例恰到好处。钨是一种源自山特维克在奥地利的矿山或回收刀片的有限原材料。钴、钛和所有其他成分均来自精心挑选的供应商,这些供应商可以确保始终如一的质量,而不会影响成品的质量。尽管如此,每批产品都必须在实验室进行严格的安全测试。然后将主要成分自动分配到称重线沿线不同站点的容器中。对于某些刀片,需要手动添加少量特殊成分。经过所有不同的站点后,整个集装箱将重达数百公斤。

下一步是研磨,将容器中的成分与乙醇、水和有机化合物混合,研磨至所需粒径:通常为0.1~5微米直径。这个过程需要8~55小时,取决于成品的配方。该化合物是一种灰色浆液,其稠度类似于酸奶饮料。然后将浆料泵入喷雾干燥器,喷雾干燥器用热氮气蒸发乙醇和水的混合物。

当粉末干燥时,它由直径约 100 微米的球形颗粒组成。样品被送到实验室进行质量检验。然后,将制成的粉末装入较小的桶中,通过压制机加工,其中有机化合物作为粘合剂,压制后粉末粘合在一起。特定刀片的模具到位后,模具的内腔将充满粉末。该机床在制造单个刀片时可以施加50吨的压力。即使整个过程的自动化程度很高,每个刀片仍然会被称重,然后操作人员会在一定的时间间隔进行外观控制,以确保最高的质量和准确性。在这个阶段,刀片还很脆弱,所以下一步就是进入烧结炉。

Why is sintering a complicated process

烧结炉一次可以烧结数千个刀片。刀片被加热到1500℃左右,这个过程大约需要13个小时,压粉被熔化成硬质合金,这是一种极硬的材料。但是,这个过程会导致严重的收缩:烧结刀片的尺寸只有压制零件尺寸的一半左右。再次送实验室进行质检后,将刀片的顶部和底部研磨至正确的厚度。由于硬质合金非常坚硬,因此需要使用含有 1.5 亿个工业金刚石小颗粒的砂轮将其磨削到正确的厚度。通常,刀片必须再次抛光以达到其精确的凹槽形状和尺寸。

This is a key step in the manufacturing process. The use of 6-axis grinder can ensure very strict tolerance, so that there has been a joke in Kimmer factory: “if you sneeze, the tolerance will change immediately”.

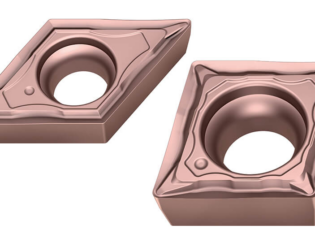

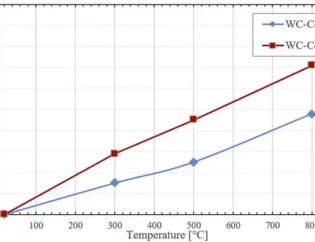

Clean and coat the blade immediately after grinding. To avoid any grease or dust, gloves must be worn when taking the blade. There are two different coating methods of blade coating: chemical vapor deposition (CVD) and physical vapor deposition (PVD). In a typical CVD, the blade substrate is contacted with one or more volatile coating gases, which react on the surface of the blade substrate to generate the required deposits. The physical vapor depositio