Semente karbür, 9 çeşit IVA, VA metal karbürden ve Fe, CO ve Ni gibi grup ve demir grubu metallerden oluşan toz metalurjisi ile yapılan bir alaşım türüdür. Karbür fazı alaşıma yüksek sertlik ve aşınma direnci verirken, bağlayıcı faz alaşıma belirli bir güç ve tokluk verir.

According to the composition, cemented carbides can be divided into five categories: tungsten carbide based cemented carbides, titanium carbide based cemented carbides, coated cemented carbides, steel based cemented carbides and other cemented carbides.

According to its application scope, cemented carbide can be divided into four categories: cemented carbide cutting tools, cemented carbide molds, cemented carbide measuring tools and wear-resistant parts, and cemented carbide for mining and petroleum geology.

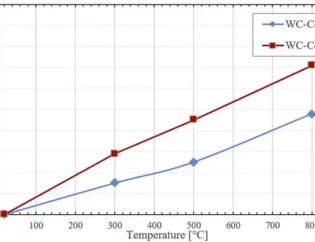

Generally speaking, WC Co cemented carbide is widely used in cutting tools, metal drawing dies, stamping dies, measuring tools of cast iron, non-ferrous metals and their alloys, as well as wear-resistant parts for mining machinery and geological exploration; WC Ti Co alloys are mainly used in steel cutting; WC TiC – (NBC) – Co alloys are mainly used for cutting high hardness parts.

Although other types of cemented carbides have made great progress in recent years and achieved great success in some special applications, WC Co series cemented carbides (i.e. YG type) have excellent comprehensive mechanical properties, which are the most widely used and the largest amount of cemented carbides in industry.

Problems in brazing of cemented carbide

The brazing property of cemented carbide is poor. This is because the carbon content of cemented carbide is high, the surface without cleaning often contains more free carbon, which hinders the wetting of solder. In addition, cemented carbide is easy to oxidize and form oxide film at brazing temperature, which also affects the wettability of solder. Therefore, the surface cleaning before brazing is very important to improve the wettability of solder on cemented carbide. If necessary, the surface can be plated with copper or nickel.

Another problem in cemented carbide brazing is that the joint is easy to crack. This is because its coefficient of linear expansion is only half of that of low carbon steel. When the cemented carbide is brazed with the matrix of this kind of steel, great thermal stress will be produced in the joint, resulting in the cracking of the joint. Therefore, when brazing cemented carbide with different materials, anti cracking measures should be taken.

Surface treatment before brazing

Before brazing, the oxide, grease, dirt and paint on the surface of the workpiece must be carefully removed, because the melted solder cannot wet the surface of the part that has not been cleaned, nor can it fill the joint gap. Sometimes, in order to improve the brazeability of base metal and the corrosion resistance of brazed joint, the parts must be pre coated with a certain metal layer before brazing.

1. The oil can be removed by organic solvent

Commonly used organic solvents are alcohol, carbon tetrachloride, gasoline, trichloroethylene, dichloroethane and trichloroethane. In small batch production, it can be cleaned by immersing the zero ash in organic solvent. Degreasing in steam of organic solvent is widely used in mass production. In addition, cleaning in hot alkali solution can also get satisfactory results. For example, steel parts can be dipped into 10% caustic soda solution at 70-80 ℃ for degreasing, copper and copper alloy parts can be cleaned in a solution of 50g trisodium phosphate, 50g sodium bicarbonate and 1L water, and the solution temperature is 60-80 ° C. Parts can also be degreased in detergent and cleaned carefully with water after degreasing. When the part surface can be completely wetted by water, it indicates that the surface grease has been removed. For the small parts with complex shape and large quantity, ultrasonic cleaning can also be used in the special tank. Ultrasonic oil removal efficiency is high.

2. Remove oxide

Before brazing, the oxide on the surface of parts can be removed by mechanical method, chemical etching method and electrochemical etching method. When cleaning by mechanical method, it can use file, metal brush, sandpaper, grinding wheel, sand blasting to remove the oxide film on the surface. The file and sandpaper cleaning are used for single piece production, and the groove formed during cleaning is also conducive to the wetting and spreading of solder. Grinding wheel, metal brush and sand blasting are used in batch production. The surface of aluminum, aluminum alloy and titanium alloy should not be cleaned mechanically.

3. Metal plating on base metal surface

The main purpose of coating metal on the base metal surface is to improve the solderability of some materials and increase the wettability of solder to the base metal; Prevent the base metal and solder interaction on the joint quality of adverse effects, such as to prevent cracks, reduce the interface of brittle intermetallic compounds; As a solder layer, to simplify the assembly process and improve productivity.

Brazing materials

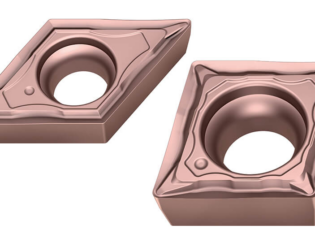

1. Pure copper, copper zinc and silver copper are usually used for brazing tool steel and cemented carbide

Pure copper has good wettability to all kinds of cemented carbides, but it needs to be brazed in the reducing atmosphere of hydrogen to get the best effect. At the same time, due to the high brazing temperature, the stress in the joint is large, which leads to the increase of crack tendency. The shear strength of the joint brazed with traditional pure copper is about 150MPa, and the joint has high plasticity, but it is not suitable for high temperature work.

Copper zinc solder is the most commonly used solder for brazing tool steel and cemented carbide. In order to improve the wettability of solder and the strength of joint, alloy elements such as Mn, Ni and Fe are often added to solder. For example, the addition of W (MN) 4% in b-cu58znmn makes the shear strength of cemented carbide brazed joint reach 300-320 MPa at room temperature and 220-240 MPa at 320 ° C. By adding a small amount of CO on the basis of b-cu58znmn, the shear strength of the brazed joint can reach 350 MPa, and it has high impact toughness and fatigue strength, which can significantly improve the service life of cutting tools and rock drilling tools.

The melting point of silver copper solder is low, and the thermal stress of brazed joint is small, which is helpful to reduce the cracking tendency of cemented carbide during brazing. In order to improve the wettability of solder and increase the strength and working temperature of joint, alloy elements such as Mn and Ni are often added to solder. For example, the wettability of b-ag50cuzncdni solder to cemented carbide is excellent, and the brazed joint has good comprehensive properties.

In addition to the above three types of solders, Mn based and Ni based solders, such as b-mn50nicucrco and b-ni75crsib, can be used for cemented carbides working above 500 ° C and requiring high joint strength. For the brazing of high speed steel, the special brazing filler metal with brazing temperature matching with quenching temperature should be selected. The brazing filler metal can be divided into two types: one is ferromanganese type, which is mainly composed of ferromanganese and borax. The shear strength of the brazed joint is generally about 100MPa, but the joint is prone to crack; the other is special copper alloy containing Ni, Fe, Mn and Si, The joint brazed with it is not easy to crack, and its shear strength can be increased to 300mpa.

2. Flux and shielding gas

The choice of flux should match with the base metal and solder. When brazing tool steel and cemented carbide, the main flux used is borax and boric acid, and some fluorides (KF, NaF, CaF2, etc.) are added. Fb301, fb302 and fb105 fluxes are used for copper zinc solder, and fb101-fb104 fluxes are used for silver copper solder. Borax flux is mainly used for brazing high speed steel with special filler metal.

In order to prevent oxidation of tool steel during brazing heating and avoid cleaning after brazing, gas shielded brazing can be used. The protective gas can be inert gas or reducing gas, and the dew point of the gas should be lower than – 40 ℃. Cemented carbide can be brazed under the protection of hydrogen, and the dew point of hydrogen should be lower than – 59 ℃.

brazing process

The tool steel must be cleaned before brazing, and the machined surface does not need to be too smooth to facilitate the wetting and spreading of material and flux. Before brazing, the surface of cemented carbide should be sandblasted, or polished with silicon carbide or diamond grinding wheel to remove excessive carbon, so as to be wetted by solder during brazing. The cemented carbide containing titanium carbide is difficult to be wetted. The wettability of strong solder can be increased by coating copper oxide or nickel oxide paste on its surface and baking it in reducing atmosphere.

It is better to braze carbon tool steel before or at the same time of quenching process. If brazing is carried out before the quenching process, the solidus temperature of the solder used should be higher than the quenching temperature range, so that the weldment will still have enough strength when reheated to the quenching temperature without failure. When brazing and quenching are combined, solder with solidus temperature close to quenching temperature should be selected.

The composition range of alloy tool steel is very wide. According to the specific steel grade, the appropriate brazing filler metal, heat treatment process and the technology of combining brazing and heat treatment process should be determined, so as to obtain good joint performance.

The quenching temperature of high speed steel is generally higher than the melting temperature of silver copper and copper zinc solder, so it is necessary to carry out quenching before brazing and brazing during or after secondary tempering. If quenching must be carried out after brazing, only the special brazing filler metal mentioned above can be used for brazing. When brazing high-speed steel tools, it is more appropriate to use coke oven. When the solder melts, take out the tool and immediately pressurize, extrude the excess solder, then oil quench, and then temper at 550 ~ 570 ℃.

When brazing cemented carbide blade with steel tool bar, it is better to increase the gap between the brazing seam and apply plastic compensation gasket in the brazing seam, and cool slowly after welding, so as to reduce the brazing stress, prevent cracks and prolong the service life of cemented carbide tool assembly.

Cleaning after brazing

Most of the flux residue can corrode the brazed joint and hinder the inspection of the brazed joint, so it needs to be cleaned up. The flux residue on the weldment is firstly washed with hot water or general deslagging mixture, and then pickled with appropriate pickling solution to remove the oxide film on the base tool bar. However, be careful not to use nitric acid solution to prevent corrosion of brazing metal. The residue of organic soft flux can be wiped or cleaned with gasoline, alcohol, acetone and other organic solvents; The residues of zinc oxide and ammonium chloride are highly corrosive, so they should be cleaned in 10% NaOH solution, and then cleaned with hot water or cold water. The residues of borax and boric acid flux are generally solved by mechanical method or long-time soaking in boiling water.

Inspection of brazing quality

The inspection methods of brazed joint can be divided into non-destructive inspection and destructive inspection. The main methods of NDT are as follows:

Appearance inspection

Staining test and fluorescence test. These two methods are mainly used to check the micro cracks, air holes, porosity and other defects that can not be found by appearance inspection.