Development History of Carbide Cutting Tools

The rapid development of cutting tools came in the late 18th century, paralleling the growth of machinery such as the steam engine. In 1783, René in France was the first to create a milling cutter. In 1792, Maudslay in the UK produced tap and die sets. The earliest documented reference to the invention of the twist drill dates back to 1822, but it wasn’t until 1864 that it became commercially produced. Tools at that time were made from integral high-carbon tool steel, with permissible cutting speeds of about 5 meters per minute.

In 1868, Mushet in the UK created alloy tool steel containing tungsten. In 1898, Taylor and White in the US invented high-speed steel. In 1923, Schröter in Germany invented hard alloys.

The use of alloy tool steel increased cutting speeds to around 8 meters per minute, high-speed steel raised it more than twice that, and with the use of hard alloys, it increased by more than twice again. The surface quality and dimensional accuracy of workpieces from cutting operations also significantly improved.

Due to the relatively high cost of high-speed steel and hard alloys, welded and mechanically clamped structures were introduced in tooling. Between 1949 and 1950, the US began to use indexable inserts on lathe tools, which soon extended to milling cutters and other tools. In 1938, Degussa in Germany obtained a patent for ceramic cutting tools. In 1972, General Electric in the US produced polycrystalline synthetic diamond and polycrystalline cubic boron nitride inserts. These non-metallic tool materials enabled tools to cut at even higher speeds.

In 1969, Sandvik in Sweden obtained a patent for producing cemented carbide inserts with titanium carbide coatings using chemical vapor deposition. In 1972, Bondhus and Laguiole in the US developed physical vapor deposition, coating cemented carbide or high-speed steel tool surfaces with titanium carbide or titanium nitride hard layers. Surface coating methods combine the high strength and toughness of the base material with the high hardness and wear resistance of the surface layer, resulting in better cutting performance for these composite materials.

Categorizing Carbide Cutting Tools by Application

Cutting tools can be classified into five categories based on the form of the workpiece’s machined surface. These include tools for processing various external surfaces, such as turning tools, planing tools, milling cutters, external grooving tools, and files; tools for hole machining, such as drills, reamers, boring tools, countersinks, and internal grooving tools; thread processing tools, including taps, dies, automatic opening and closing thread chasers, thread turning tools, and thread milling cutters; gear processing tools, including hob cutters, gear shapers, gear shaving cutters, and bevel gear processing tools; and cutting-off tools, including inserted-tooth circular saw blades, band saws, hacksaws, cut-off turning tools, and saw-milling cutters, among others. Additionally, there are combination tools.

Based on the cutting motion and corresponding blade shape, cutting tools can be further classified into three categories. General-purpose tools, such as turning tools, planing tools, milling cutters (excluding form turning tools, form planing tools, and form milling cutters), boring tools, drills, reamers, and saws; form tools, where the blade shape of these tools matches or closely approximates the profile of the workpiece, including form turning tools, form planing tools, form milling cutters, broaches, tapered reamers, and various thread processing tools; gear generation tools used to machine gear teeth or similar workpieces using gear generating methods, such as hob cutters, gear shapers, gear shaving cutters, and bevel gear planing tools.

Categorizing Carbide Cutting Tools by Form

Tools with handles typically come in three types: rectangular handle, cylindrical handle, and taper handle. Turning tools, planing tools, and others generally have a rectangular handle. Taper handles are designed to withstand axial thrust and transmit torque through frictional forces. Cylindrical handles are typically used for smaller tools like twist drills and end mills, and the torque is transmitted through friction generated during clamping. The handle of many tools is made from low-alloy steel, while the working part is bonded with high-speed steel, combining the two parts.

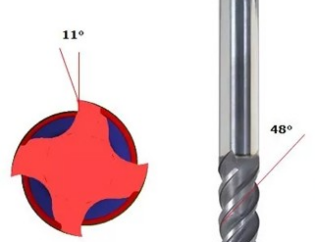

The working part of a cutting tool is the section responsible for generating and handling chips. It includes the cutting edge, structures that break or curl the chips, spaces for chip evacuation or storage, channels for cutting fluid, and other structural elements. For some tools, the working part is solely the cutting section, such as turning tools, planing tools, boring tools, and milling cutters. For others, the working part includes both the cutting section and the calibration section, such as drills, reamers, countersinks, internal grooving tools, and taps. The cutting section’s role is to remove chips using the cutting edge, while the calibration section’s role is to finish the machined surface and guide the tool.

Principles of Selecting Cutting Tool Materials

When selecting cutting tools, various factors need to be considered, such as the workpiece material, tool material, and machining characteristics (rough or finish machining). The choice must be made based on the specific circumstances.

High-speed steel remains the most widely used tool material in modern times due to its high bending strength, impact toughness, and good machinability. Carbide follows as the second most popular choice.

Polycrystalline cubic boron nitride is suitable for cutting high-hardness quenched steel, hardened cast iron, and similar materials. Polycrystalline diamond is suitable for cutting non-ferrous metals, alloys, plastics, and fiberglass. Carbon tool steel and alloy tool steel are now only used for tools like files, taps, and dies.

Carbide Cutting Tool Grades

Cutting tool carbide grades are categorized into six types based on their application fields: P, M, K, N, S, and H, each used for specific purposes:

P: Cutting long chips in materials like steel, cast steel, and malleable cast iron.

M: General alloy machining, including alloy steel, alloy cast iron, stainless steel, and manganese steel.

K: Cutting short chips in materials like gray cast iron.

N: Processing non-ferrous metals and non-metallic materials.

S: Machining heat-resistant and high-quality alloy materials.

H: Cutting hard materials such as quenched steel and cold-hardened cast iron.

Each category has subgroup numbers, such as 01, 10, 20, 30, and 40 for P, M, K, and 01, 10, 20, 30 for N, S, H. Within each subgroup, as the number increases, the hardness decreases, while the bending strength increases.

The basic composition of P-grade alloys consists of TiC and WC as the base, with Co (or Ni) as the binder. M to H grades all have WC as the base and Co as the binder, sometimes with the addition of TaC and NbC.

Tungsten-cobalt (WC-Co) alloys are the most widely used carbide materials, consisting mainly of tungsten carbide (WC) and cobalt (3% to 30%). When used for cutting tools, the Co content ranges from 3% to 13%, and the average WC grain size is 1 to 5 μm. In the case of tooling, the Co content can reach up to 30%, with an average WC grain size of 10 μm.

WC-Co carbide can be used for cutting cast iron, non-ferrous metals, and non-metallic materials. It can also be used for drawing dies, cold heading dies, and measuring and cutting tools. The carbide can be categorized into low-cobalt, medium-cobalt, and high-cobalt alloys based on cobalt content, and into microcrystalline, fine crystalline, medium crystalline, and coarse crystalline alloys based on WC grain size.