Two primary factors that influence tool life significantly:

Cutting Speed (Linear Velocity)

Cutting speed has a noticeable impact on tool life. If the cutting speed exceeds 20% of the specified speed for the material being machined, the tool life will be reduced to half of its original duration. If it increases to 50% above the specified speed, the tool life will be reduced to only one-fifth of its original duration.

Vibration

In addition to cutting speed, vibration also has a significant effect on tool life. The main reason for vibration is the rigidity of the machining setup. Vibration on the workpiece’s surface is seen as continuous hammering between the tool and the workpiece, rather than normal cutting. This can increase the degree of tool chipping and fracturing, thereby greatly reducing the tool’s lifespan.

Estimation Methods for the Service Life of CNC Tools

Estimated Based on Cutting Time

In the metal cutting tool industry, a cutting speed recommendation is typically made based on a CNC tool life of 15 minutes. In practical applications, it is common to use 75% of the recommended value provided by the CNC tool manufacturer. At this reduced cutting speed, the estimated tool life for CNC tools is approximately 60 minutes.

The estimated number of workpieces that can be processed by a single cutting edge can be calculated using the following formula:

N = (19100 * V * f) / (D * h)

Where: N: Tool life, the number of workpieces that can be processed (unit: pieces) V: Cutting speed selected for the tool (unit: meters per minute) f: Feed rate during machining (unit: millimeters per revolution) D: Diameter of the workpiece being machined (unit: millimeters) h: Machining length (unit: millimeters)

Turning a workpiece with a diameter of 60 millimeters and a length of 110 millimeters. The tool manufacturer recommends a cutting speed of 200 meters per minute. The planned tool cutting time life T is 60 minutes. The actual cutting speed used is 150 meters per minute, and the feed rate is 0.1 millimeters per revolution. Calculate the estimated tool life:

N = (19100 * 150 * 0.1) / (60 * 110) = 43.4

Under the given conditions, each cutting edge can process approximately 43 workpieces.

Calculating CNC Tool Life Based on Cutting Distance

Cutting distance refers to the total distance traveled by a cutting edge, assuming that a single cutting edge continuously cuts on a very large workpiece at a constant speed from the beginning to failure. This distance is known as the cutting distance life and is denoted by “L.”

The estimated number of workpieces that a single cutting edge can process can be calculated using the following formula:

N = (318300 * L * f) / (D * h)

Where: N: Tool life, number of workpieces that can be processed L: Estimated cutting distance life, measured in kilometers f: Feed rate during machining, measured in millimeters per revolution D: Diameter of the workpiece being machined, measured in millimeters h: Length of the machining, measured in millimeters

For example, when turning a workpiece with a diameter of 50 millimeters and a length of 100 millimeters, with a feed rate of 0.1 millimeters per revolution, and the cutting distance life recommended by the tool manufacturer is 10 kilometers, the estimated tool life can be calculated as follows:

N = (318300 * 10 * 0.1) / (50 * 100) = 63.66

Under the given conditions, each cutting edge can process approximately 63 workpieces.

Estimated Tool Life Based on Empirical Values

Experienced professionals in the industry, with their wealth of experience, can directly estimate the tool’s service life for machining specific materials using common materials and commonly used CNC tools.

For example, for coated hard alloy drill bits with diameters ranging from Φ25 to Φ30, when drilling into ordinary carbon steel, the cumulative drilling length is approximately 20 to 30 meters. When machining cast iron, it is generally around 80 to 100 meters in cumulative total length.

The three estimation methods mentioned above are only rough estimates under typical circumstances. Whether estimating based on cutting time or cutting distance, these methods tend to be conservative. Generally, tool manufacturers do not provide these estimation methods, as the calculation methods for CNC tools are determined in specific laboratory environments and may not be applicable as general guidelines.

Methods to Improve Tool Life

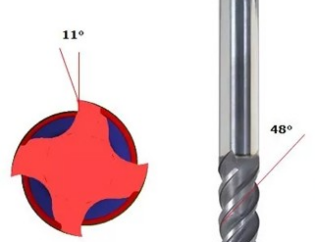

Improve matrix

By varying the particle size of tungsten carbide within the range of 1-5μm, tool manufacturers can alter the matrix properties of cemented carbide tools. The particle size of the matrix material plays a crucial role in cutting performance and tool life. Smaller particle sizes result in better wear resistance for the tool, while larger particle sizes enhance the tool’s toughness.

Furthermore, increasing the cobalt content in cemented carbide CNC tool materials by 6% to 12% can enhance toughness. Therefore, specific cutting process requirements, whether for toughness or wear resistance, can be met by adjusting the cobalt content.

The performance of tool substrates can also be enhanced by forming a cobalt-rich layer near the outer surface or selectively adding other alloying elements (such as titanium, tantalum, vanadium, niobium, etc.) to the cemented carbide material. A cobalt-rich layer can significantly improve cutting edge strength, thereby enhancing the performance of rough machining and interrupted cutting tools.

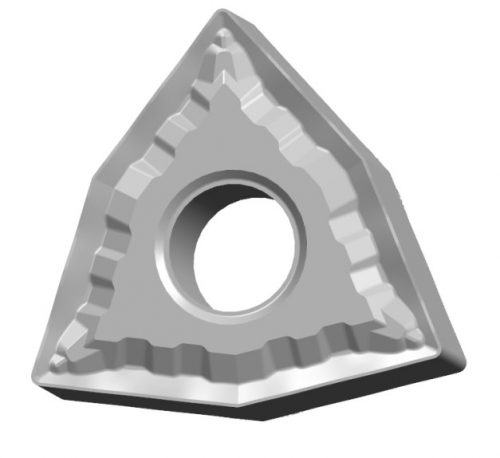

Choose suitable coating

Coatings also contribute to improving the cutting performance of cemented carbide CNC tool inserts. Current coating technologies include:

1Titanium Nitride (TiN) Coating: This is a universal PVD and CVD coating that enhances the tool’s hardness and oxidation temperature.

2Titanium Carbonitride (TiCN) Coating: By adding carbon elements to TiN, this coating improves hardness and surface smoothness.

3Titanium Aluminum Nitride (TiAlN) and Aluminum Titanium Nitride (AlTiN) Coatings: The application of aluminum oxide (Al2O3) layers in conjunction with these coatings can enhance the tool life in high-temperature cutting processes. Aluminum oxide coatings are particularly suitable for dry and near-dry cutting.

4Chromium Nitride (CrN) Coating: This coating exhibits good anti-adhesion properties and serves as a solution to combat chip adhesion.

Honing edge

In many cases, the preparation of blade cutting edges (or edge honing) has become a critical factor in determining the success of machining. The honing process parameters need to be determined based on specific machining requirements. The honing amount can range from as small as 0.007mm to as large as 0.05mm. Generally, blades used for continuous turning and milling of most steels and cast irons require a significant degree of edge honing. The honing amount depends on the grade of the cemented carbide and the type of coating (CVD or PCD coating). For heavy-duty interrupted cutting inserts, substantial edge honing or machining of T-shaped lands has become a prerequisite.

Conversely, because blade inserts used for machining stainless steel and high-temperature alloys tend to form chip accumulations, they require sharp cutting edges and can only undergo slight honing (as low as 0.01mm), or even smaller honing amounts can be customized. Similarly, inserts used for machining aluminum alloys also require sharp cutting edges.