Causes of Roughness Issues

The poor roughness may be attributed to the following reasons:

1.Improper tool selection: Severe tool wear or poor quality can lead to issues such as burrs and cracks on the drilled surface.

2.Cutting speed too fast or too slow: Excessive cutting speed can result in a rough machining surface, while too slow a speed may lead to an unsmooth surface.

3.Improper use of coolant: Incorrect use of coolant, such as low concentration or contaminated coolant, can also result in an unsmooth surface on the drilled hole.

4.Incorrect machining parameter settings: Incorrect machining parameter settings may cause unstable cutting, thereby resulting in an unsmooth surface on the drilled hole.

Principles for Resolving Roughness Issues

To address the issue of poor machining roughness, it is necessary to address specific reasons, and the specific methods are as follows:

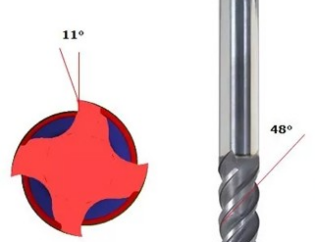

1.Pay attention to tool selection: Choose high-quality, rigid, and minimally wearing tools.

2.Select the appropriate cutting speed: Adjust the cutting speed based on the machining material and drill bit material to ensure cutting quality.

3.Make rational use of coolant: Choose coolant with an appropriate concentration, maintain the cleanliness of the coolant, and replace it in a timely manner.

4.Set machining parameters reasonably: According to the material and drill bit conditions, set cutting speed, feed rate, and start frequency, among other machining parameters, in a reasonable manner.

Improving roughness through cutting parameter adjustments

The three elements of cutting conditions—cutting speed, feed rate, and depth of cut—directly cause tool damage. With the increase in cutting speed, the temperature at the tool tip rises, leading to mechanical, chemical, and thermal wear. A 20% increase in cutting speed results in a 50% reduction in tool life.

The relationship between feed conditions and tool wear occurs within a very narrow range. However, a large feed rate increases cutting temperature and leads to significant wear. Its impact on the tool is smaller compared to cutting speed. While the depth of cut has a smaller impact on the tool than cutting speed and feed rate, during micro-cutting, a hardened layer is produced in the machined material, also affecting tool life.

Users should choose the cutting speed based on factors such as the processed material, hardness, cutting conditions, material type, feed rate, and depth of cut. The selection of the most suitable processing conditions is based on these factors. Ideally, regular and stable wear reaching the tool’s lifespan is considered optimal.

However, in practical operations, the choice of tool life is related to tool wear, changes in the machined dimensions, surface quality, cutting noise, machining heat, etc. When determining processing conditions, research should be conducted based on the actual situation. For difficult-to-machine materials like stainless steel and heat-resistant alloys, coolant can be used, or blades with good rigidity can be selected.

The correct selection of these three elements is a major focus of the principles of metal cutting courses.

Cutting speed (linear speed, circumferential speed) V (meters per minute)

To choose the spindle speed per minute, it is necessary to first determine the appropriate cutting speed V. The selection of V depends on the tool material, workpiece material, and processing conditions.

Tool material

For carbide, a higher V can be chosen, generally above 100 meters per minute. Technical parameters are usually provided when purchasing blades, indicating the recommended cutting speeds for different materials. For high-speed steel, V can only be lower, generally not exceeding 70 meters per minute, often ranging from 20 to 30 meters per minute.

Workpiece material

For materials with high hardness, a lower V is chosen. For cast iron, a lower V is selected. When the tool material is carbide, a speed of 70 to 80 meters per minute can be chosen. For low carbon steel, V can be above 100 meters per minute, and for non-ferrous metals, a higher speed (100 to 200 meters per minute) can be chosen. For hardened steel and stainless steel, V should be chosen lower.

İşleme koşulları

For rough machining, a lower V is chosen, while for finishing, a higher V is chosen.

If the rigidity system of the machine tool, workpiece, and tool is poor, a lower V should be chosen.

If the numerical control program uses S as the spindle speed per minute, then S should be calculated based on the workpiece diameter and cutting speed V: S (spindle speed per minute) = V (cutting speed) * 1000 / (3.1416 * workpiece diameter).

If the numerical control program uses constant linear speed, then S can directly use the cutting speed V (meters per minute).

Feed Rate (Cutting Depth)

The feed rate, denoted as F, is primarily determined by the surface roughness requirements of the workpiece. In precision machining, where a high surface finish is required, a smaller feed rate is chosen, typically ranging from 0.06 to 0.12 mm per revolution of the spindle. For rough machining, a larger feed rate can be chosen.

The selection of the feed rate is mainly influenced by tool strength and is generally chosen to be 0.3 or higher. When the tool’s main clearance angle is large, resulting in lower tool strength, the feed rate should not be too high. Additionally, considerations should be given to the power of the machine tool, as well as the rigidity of both the workpiece and the tool.

Numerical control programs can use two units for the feed rate: mm/minute or mm/spindle revolution. The units used above are in mm/spindle revolution. If mm/minute is used, the conversion formula is as follows: Feed rate per minute = Feed rate per revolution * Spindle revolutions per minute.

Cutting Depth

In precision machining, the cutting depth is generally chosen to be below 0.5 (in terms of radius). For rough machining, the selection depends on the workpiece, tool, and machine tool conditions. For small lathes (with a maximum processing diameter below 400mm) turning annealed 45# steel, the radial cutting depth generally does not exceed 5mm.

It’s important to note that if the lathe’s spindle speed control uses ordinary frequency conversion speed regulation, when the spindle speed is very low (below 100-200 revolutions per minute), the motor output power will significantly decrease. In such cases, the cutting depth and feed rate can only be chosen to be very small.