超硬合金インサートの処理におけるブラスト洗浄プロセス

業界の急速な発展に伴い、最新の高速機械加工と自動工作機械は、工具の性能と安定性に対するより高い要件を提唱しています。超硬合金は、その高い硬度、耐摩耗性、強度と靭性、耐熱性、耐食性により、ブレードの製造に広く使用されています。超硬インサートには複雑な製造プロセスがあり、サンドブラストプロセスの重要なプロセスは、ブレードコーティングの接着強度と外観に直接影響します。耐用年数は決定的な役割を果たします。

サンドブラスト処理

サンドブラストは、ドライブラスト洗浄とウェットブラスト洗浄に分かれています。ドライブラストクリーニングは、砂の材料をワークピースの表面に直接吹き付ける圧縮空気によって形成される一種のクリーニング方法です。ウェットブラストクリーニングは、砂と水の混合物をワークピースの表面に送り込む圧縮空気によって形成される一種のクリーニングです。処理方法。

通常、通常のブレード(あり)は、焼結後にドライブラストクリーニングでクリーニングされ、CNCブレード(あり)コーティングはウェットブラストクリーニングでクリーニングされます。通常のブレードを焼結した後、表面に凹凸があり、不純物があります。通常、粗い白いコランダムで洗浄されます。サンドブラスト後、不純物を効果的に除去し、均一な表面を得ることができます。ウェットブラスト洗浄は、最も環境に優しいブラスト洗浄として知られています。それはあらゆる種類の超硬工具の処理に適し、粉塵はありません。一種のPVDおよびCVDブレードコーティング技術です。ウェットブラスト洗浄プロセスは海外にあります。超硬合金業界で広く使用されています。カーバイドインサートへのウェットブラストクリーニングの適用は、3つの側面で具体化されています:

1.ブレード(付き)の表面粗面化洗浄

ウェットブラストクリーニングでは、超硬合金インサートの表面をコーティング前に均一に粗くすることができます。研磨剤は通常、粗い白いコランダムでできています。洗浄後、所望の粗さの値を得ることができ、材料の表面の残留圧縮応力を低減することができます。材料の表面のCo含有量を減らし、  超硬合金インサートのブレード、およびウェットブラスト前処理後のPVDおよびCVD蒸着コーティングにより、コーティングと基板のインターフェース間の結合力が向上します。層の耐摩耗性とブレードの耐用年数が大幅に向上し、コーティングされたブレード(ウィズ)の切削性能が向上します。

超硬合金インサートのブレード、およびウェットブラスト前処理後のPVDおよびCVD蒸着コーティングにより、コーティングと基板のインターフェース間の結合力が向上します。層の耐摩耗性とブレードの耐用年数が大幅に向上し、コーティングされたブレード(ウィズ)の切削性能が向上します。

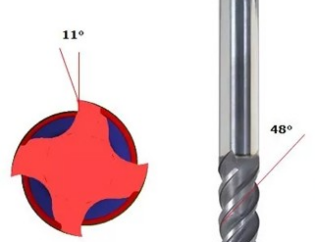

2.ブレード(と)の最先端のパッシベーションクリーニング

ブレード切断技術は、工具寿命を改善し、工具消費を削減するための効果的な対策の1つです。その経済性と技術の向上は不可欠であり、中国の切削加工レベルの向上をさらに促進し、外国の工具の切削性能を低下させます。ギャップ。 CVDコーティングインサート(あり)では、コーティングする前に工具の刃先を不動態化する必要があります。 CNC工作機械の最先端と海外から輸入された生産ラインはすべて不動態化されています。実用的な調査によると、ツールエッジのパッシベーションは200%以上でツールの寿命を効果的に延ばし、ツールのコストを大幅に削減し、ユーザーに大きな経済的利益をもたらします。

従来のパッシベーションプロセスでは、通常の砥石またはダイヤモンド砥石を使用して刃を(刃先で)研いでおり、研ぎ後の刃先には微視的なノッチの程度、つまりマイクロチッピングと切り口があります。前者は肉眼と通常の拡大鏡で観察できます。後者は、100倍の顕微鏡(0.010 mmのライン)で、一般的に0.01 mmから0.05 mmの範囲の微視的ギャップと、最大0.1 mm以上の深刻なケースで観察できます。工具の刃先のマイクロノッチは、切削プロセス中に容易に拡張され、工具の摩耗と損傷を促進します。

ウェットブラストによるパッシベーション洗浄は、通常、テストに成功して使用されている微細な白い溶融アルミナで行われます。ウェットブラストの不動態化の目的は、鋭利化後に工具の刃先のマイクロノッチの欠陥を解決することです。これにより、正面値が減少または排除され、刃先強度が効果的に向上し、工具寿命と切削の安定性が向上します処理する。不動態化されたブレードにより、コーティングの品質が向上し、エッジ値が減少し、コーティングの堅牢性と寿命が向上します。工具材料、工具形状、工具構造、および切削量の最適化に加えて、工具切削性能と工具寿命に影響を与える多くの要因があります。

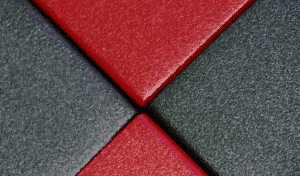

3.ブレード(有)コーティング研磨

超硬合金インサート(有)コーティング後、コーティングの表面はくすんでおり、外観は正常です。ウェットブラストで洗浄し、細かい白いコランダムまたはガラスビーズで洗浄して、コーティングの表面をさらに細かくし、表面に金属光沢を与え、美しいグレージング効果を実現し、製品の外観を改善します。