什么是旋转分度加工?

定义

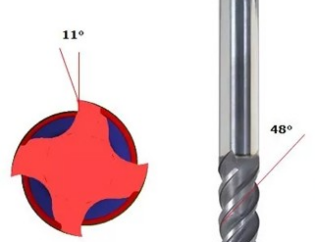

旋转分度加工,简称旋转分度,是指刀具和工件同时旋转,实现切削和分度的加工方法。通过调整它们之间的速比,可以加工不同类型的零件。适用于加工表面呈圆形分布的零件,如齿轮、花键等。

机制

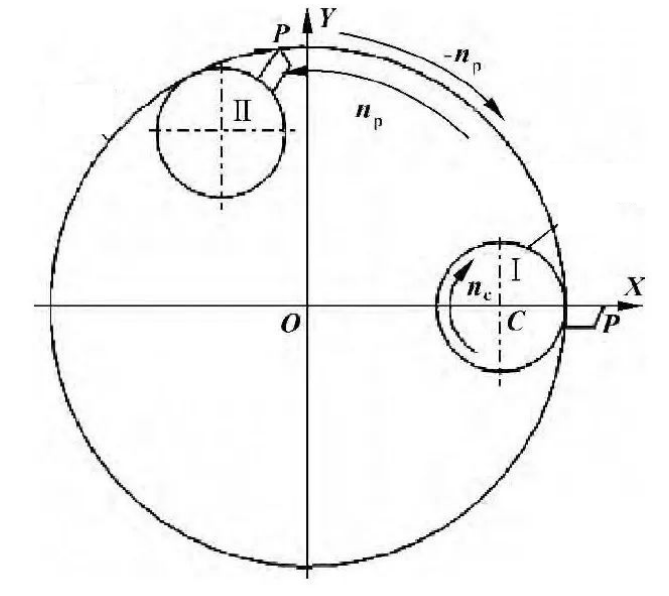

旋转分度加工的重点是控制加工过程中每个瞬间工件与刀具之间的相对位置和运动,使接触点的运动轨迹成为一条直线。这是利用数学中形成渐开线的原理,因此也称为渐开线加工。虽然听起来很简单,但它涉及复杂的数学函数。加工运动轨迹可以看作是两个运动的合成:

1、绕基圆圆心O公转,速度为np的圆周运动;

2.绕自身中心C旋转的速度为nc的圆周运动。通过调整速比等参数,可以实现不同的加工路径。详细的数学计算这里就不解释了。

旋转分度加工的优点和缺点

旋转分度加工的主要优点是将传统的间歇加工转变为间歇连续加工,节省分度时间,显着提高加工效率,获得更好的表面精度。另外,它属于干式切削,不需要切削液,在一定程度上降低了生产成本,是一种经济的加工工艺。

然而,旋转分度加工并不是一项完美的技术。当加工不同尺寸的零件时,需要重新编程,增加了操作难度。刀具磨损也比传统加工更严重。这些缺点限制了其实际应用,目前仅用于小规模生产。

旋转分度加工设备的开发

海外

德国和日本是最早探索旋转分度加工设备领域的国家。他们已经开发出相对成熟的技术并投入生产。

Germany can be considered a pioneer in the development of CNC rotary indexing machines. In the early days, they developed CNC rotary indexing cutting technology based on the needs of German car manufacturers such as Mercedes-Benz, patented it globally, and developed powerful CNC involute rotary indexing machining equipment. To this day, they are still committed to the research and development of dedicated cutting machines based on rotary indexing theory. One of the distinctive technologies of Germany’s Wera is the use of patented rotary indexing technology, combining hobbing and broaching in the method called “hob-broach.” It can machine various tooth profiles, including involute and non-involute, without the need for tool retraction grooves.

日本还开发了旋转分度机,可用于加工沟槽类零件、齿轮倒角和去毛刺以及复杂表面。

国内的

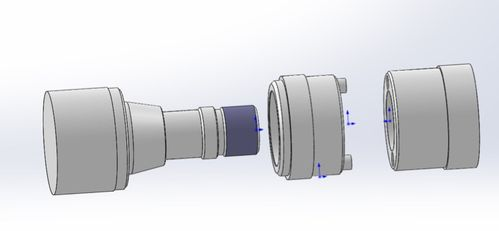

我国于2003年左右开始研究旋转分度加工,并取得了一些重要的研究成果。加工范围包括R系列槽型(小轴、盘齿、轴齿)、M系列复杂曲面(方形、六角形、多边形、组合齿)。我国高校从2002年开始研发具有自主知识产权的旋转分度加工技术和装备,重点发展旋转分度倒角加工中心。他们成功开发了旋转分度倒角加工中心,并完成了同步器齿套上凹槽和锥度倒角的加工。

However, due to factors such as strong specialization and operational difficulty, China’s CNC rotary indexing machines still have a significant gap, urgently requiring researchers to fill. Currently, most machine tools used by Chinese enterprises rely on imports, resulting in high costs.

结论

The advantage of rotary indexing machining lies in its high efficiency, reducing the machining time from minutes to tens of seconds. Although it has not been widely popularized due to current development constraints, it is still a highly promising new technology. With the joint efforts of researchers and enterprises, the future of rotary indexing machining is expected to create a new situation in China’s machining industry.