Procédé de nettoyage par grenaillage dans le traitement d'inserts en carbure cémenté

Avec le développement rapide de l'industrie, l'usinage à grande vitesse moderne et les machines-outils automatisées mettent en avant des exigences plus élevées en termes de performances et de stabilité des outils. Le carbure cémenté est largement utilisé dans la production de lames en raison de sa dureté élevée, de sa résistance à l'usure, de sa résistance et de sa ténacité, de sa résistance à la chaleur et de sa résistance à la corrosion. Les inserts en carbure ont des processus de production complexes, et un processus critique dans le processus de sablage affecte directement la force d'adhérence et l'apparence des revêtements de lame. La durée de vie joue un rôle décisif.

Processus de sablage

Le sablage est divisé en un nettoyage à sec et un nettoyage à sec. Le nettoyage à sec est une sorte de méthode de nettoyage formée par air comprimé pulvérisant directement le matériau de sable sur la surface de la pièce; Le nettoyage par projection humide est une sorte de nettoyage formé par l'air comprimé entraînant le mélange de sable et d'eau à la surface de la pièce. Méthodes de traitement.

Habituellement, la lame ordinaire (avec) est nettoyée par un nettoyage à sec après le frittage, et le revêtement de la lame CNC (avec) est nettoyé par un nettoyage humide. Une fois la lame ordinaire frittée, la surface est inégale et contient des impuretés. Il est généralement nettoyé avec du corindon blanc grossier. Après le sablage, il peut éliminer efficacement les impuretés et obtenir une surface uniforme. Le nettoyage par projection humide est connu comme le nettoyage par projection le plus respectueux de l'environnement. Il convient au traitement de toutes sortes d'outils en carbure, sans poussière. Il s'agit d'une sorte de technologie de revêtement de lame PVD et CVD. Le processus de nettoyage par projection humide est à l'étranger. A été largement utilisé dans l'industrie du carbure cémenté. L'application du nettoyage par projection humide sur des plaquettes en carbure se présente sous trois aspects:

1.Lame (avec) nettoyage de rugosité de surface

Le nettoyage par projection humide peut rendre la surface des inserts en carbure cémenté uniformément rugueuse avant le revêtement. Les abrasifs sont généralement constitués de corindon blanc grossier. Après le nettoyage, la valeur de rugosité souhaitée peut être obtenue et la contrainte de compression résiduelle sur la surface du matériau peut être réduite. Réduire la teneur en Co à la surface du matériau, éliminer la phase carbure du  lame de l'insert en carbure cémenté, et le revêtement PVD et CVD déposé après le prétraitement par projection humide améliore la force de liaison entre le revêtement et l'interface du substrat. La résistance à l'usure de la couche et la durée de vie de la lame sont considérablement améliorées, et les performances de coupe de la lame revêtue (avec) sont améliorées.

lame de l'insert en carbure cémenté, et le revêtement PVD et CVD déposé après le prétraitement par projection humide améliore la force de liaison entre le revêtement et l'interface du substrat. La résistance à l'usure de la couche et la durée de vie de la lame sont considérablement améliorées, et les performances de coupe de la lame revêtue (avec) sont améliorées.

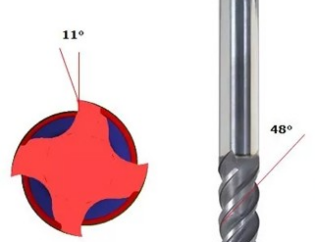

2.Lame (avec) nettoyage de passivation de pointe

La technologie de coupe des lames est l'une des mesures efficaces pour améliorer la durée de vie des outils et réduire la consommation d'outils. Son économie et son amélioration technique sont essentielles, ce qui favorise encore l'amélioration du niveau d'usinage de coupe en Chine et réduit les performances de coupe des outils étrangers. écart. Les plaquettes revêtues CVD (avec) nécessitent une passivation du tranchant de l'outil avant le revêtement. Les tranchants des machines-outils CNC et des lignes de production importées de l'étranger ont tous été passivés. La recherche pratique montre que la passivation du bord de l'outil peut effectivement prolonger la durée de vie de l'outil d'ici 200% ou plus, réduisant considérablement le coût de l'outil et apportant d'énormes avantages économiques à l'utilisateur.

Le processus de passivation conventionnel utilise généralement une meule normale ou une meule diamantée pour affûter la lame (avec) un tranchant, et le tranchant après l'affûtage a une encoche microscopique d'un degré différent, c'est-à-dire un micro-écaillage et une saignée . Le premier peut être observé à l'œil nu et à la loupe ordinaire. Ce dernier peut être observé avec un microscope de 100 fois (avec une ligne de 0,010 mm) un écart microscopique allant généralement de 0,01 mm à 0,05 mm, et des cas graves jusqu'à 0,1 mm ou plus. La micro-encoche du tranchant de l'outil se dilate facilement pendant le processus de coupe, ce qui accélère l'usure et les dommages de l'outil.

Le nettoyage par passivation par projection humide est généralement effectué avec de l'alumine fondue blanche fine, qui a été testée avec succès et est utilisée. Le but de la passivation par projection humide est de résoudre le défaut de la micro-encoche de l'arête de coupe de l'outil après l'affûtage, ce qui réduit ou élimine la valeur avant, améliore efficacement la résistance de l'arête, améliore la durée de vie de l'outil et la stabilité de la coupe processus. La lame passivée améliore la qualité du revêtement, réduit la valeur des bords et améliore la robustesse et la longévité du revêtement. De nombreux facteurs affectent les performances de coupe et la durée de vie de l'outil, en plus du matériau de l'outil, de la géométrie de l'outil, de la structure de l'outil et de l'optimisation de la quantité de coupe.

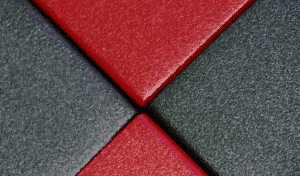

3.Lame (avec) polissage de revêtement

Après l'insert en carbure cémenté (avec) revêtement, la surface du revêtement est terne et l'aspect est normal. Il est nettoyé par projection humide et nettoyé avec du corindon blanc fin ou des billes de verre pour affiner davantage la surface du revêtement, donnant à la surface un éclat métallique, obtenant un bel effet de vitrage et améliorant l'apparence du produit.