What Is Tungsten Carbide Material?

Tungsten carbide is a hard metal that is used in manufacturing cutting tools and wear-resistant parts like molds. It can be combined with other metals to produce other types of carbides. One example of this combination is tungsten carbide-cobalt which is the most popular Tungsten carbide alloy with the combination of hard material tungsten carbide and binder material cobalt.

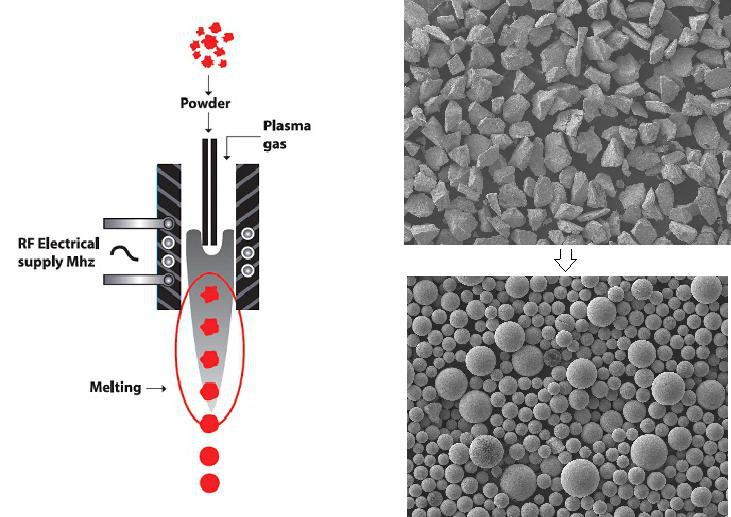

Tungsten carbide is manufactured by a series of production processes like powder mixing, pressing, sintering, and so on. During the sintering process, the binder material like cobalt will melt and help the mixing and binding of the tungsten carbide to increase the compaction and density of the final alloy.

Tungsten carbide is one of the best candidates for recycling. While it is a very valuable metal, it can also be a source of scrap. For example, scrap tungsten carbide can be melted down and refined to form new pieces of tungsten carbide.

Properties Of Tungsten Carbide Material

우리는 텅스텐 카바이드의 6가지 주요 재료 매개변수에 대해 이야기할 것입니다. 학문적으로 초경합금은 고경도 내화금속의 텅스텐 카바이드 분말(경화상)을 주성분으로 하고 코발트, 니켈 등의 금속(결합상)을 주성분으로 하여 경도가 매우 높고 내마모성이 우수한 합금재료이다. 볼밀링, 프레싱, 소결을 통한 바인더. 경도가 높고 내마모성이 좋은 금속재료라고 간단히 이해하면 됩니다. 텅스텐 카바이드는 일반적으로 물리적 특성을 위해 지정되지만 화학적 호환성은 금속 바인더에 따라 달라질 수 있습니다. 예를 들어, 니켈 결합 텅스텐 카바이드는 코발트 결합 텅스텐 카바이드보다 부식에 더 강합니다.

According to the relevant parameters of physics, the mechanical properties of cemented carbide are mainly shown in the following material parameters:

Hardness of Tungsten Carbide

The hardness of Tungsten Carbide is a function of its density, or how much of a material’s mass is contained in a unit volume. The SI unit for this property is kilograms per cubic meter, and the English unit is pounds per cubic foot. For a cubic inch of Tungsten Carbide, its density is 14.5 g/cm3. And for different grades of tungsten carbide-cobalt alloy, the density can vary from 13-15g/cm^3. And the hardness can go from HRA86 to HRA95 which is one of the hardest materials in the world, second only to diamond.

Bending strength Of Tungsten Carbide

The bending strength of cemented carbide is lower than that of high-speed steel. Even YG8 cemented carbide with high bending strength has only about half of that of high-speed steel. The higher the cobalt content in cemented carbide, the higher its strength. With the same cobalt content, the bending strength of WC tic Co alloy decreases with the increase of TiC content. In addition to the types of carbides, the size of WC grains also affects the strength of cemented carbide. The bending strength of coarse-grained cemented carbide is higher than that of medium grain cemented carbide.

Compressive strength Of Tungsten Carbide

The compressive strength of cemented carbide is very high, which can be 30%-50% higher than that of high-speed steel, about 3500-5600mpa, and the hot isostatic pressing product can reach 6000mpa. The compressive strength of cemented carbide is related to cobalt content, and the compressive strength is the largest when the cobalt content is 5%. The compressive strength of fine grain cemented carbide is greater than that of coarse grain cemented carbide, and the compressive strength of YT cemented carbide is lower than that of YG cemented carbide, which decreases with the increase of TiC content. Adding a small amount of TAC, NBC, VC, etc. can refine WC grains and improve the compressive strength.

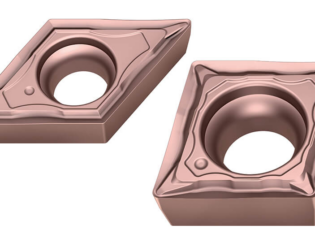

Because the compressive strength of cemented carbide is much higher than the bending strength, when designing the tool structure and selecting cemented carbide blades, we should try to make the tool head in the state of compressive stress and less bending moment.

Tensile strength Of Tungsten Carbide

The tensile strength of cemented carbide is 750-1500mpa, about 1/4 of the compressive strength. Because there are many factors that affect the plasticity of cemented carbide materials, the tensile strength of a cemented carbide is usually within a certain range.

Impact toughness Of Tungsten Carbide

The impact toughness of cemented carbide is lower than that of high-speed steel. The impact toughness of YG8 alloy with better performance is 30-40kj/m2, while that of W18Cr4V high-speed steel is 180-320kj / m2.

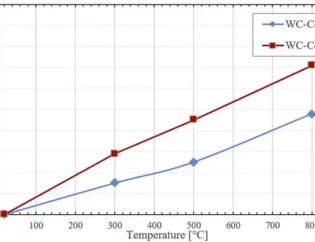

The impact toughness of cemented carbide containing tic decreases. When the tic content increases from 6% to 10%, the impact toughness decreases significantly. Temperature has a certain influence on the impact toughness of WC Co cemented carbide. At higher temperature, the impact toughness is improved.

Because the impact toughness of cemented carbide is lower than that of high-speed steel, it is not suitable to be used in the case of strong impact and vibration, otherwise it may cause cutting edge damage. The impact toughness of cemented carbide fluctuates greatly, and its absolute value is related to the test method. Therefore, when comparing the impact toughness of cemented carbide, the same instrument should be used to compare samples of the same size and shape.

Fatigue strength Of Tungsten Carbide

Because the tool usually works under dynamic conditions, its fatigue strength is very important. The higher the cobalt content in cemented carbide, the higher the fatigue strength. The fatigue strength of cemented carbide is closely related to the surface quality of the sample. The better the surface finish, the higher the fatigue strength.

Meetyou cemented carbide Co., Ltd. has provided global “customized” professional products and technical services for oil, natural gas drilling and production, chemical smelting, engineering machinery and other industries for 15 consecutive years. The company currently has 105 authorized patents, 34 invention patents, including 7 international patents, and its independently developed technology “cemented carbide composite forming technology”, Among them, the technical level of “cemented carbide high strength alloy additive manufacturing technology” is in the forefront of the world.