As the competition in the steel product quality and price market intensifies, steel companies continuously upgrade their equipment technology to enhance rolling mill speeds. Simultaneously, reducing downtime and further improving the effective operation rate of rolling mills have become crucial concerns for steel engineers. The adoption of rolls made from materials with higher rolling life is one of the essential means to achieve this goal.

Classification of carbide rolls

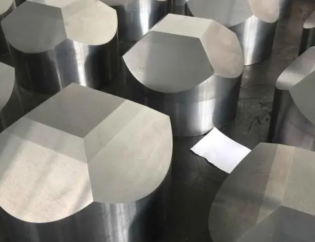

carbide rolls can be classified into integral carbide rolls and composite carbide rolls based on their structural forms.

Integral carbide rolls are widely used in the pre-finishing and finishing stands of high-speed wire rolling mills, including fixed reduction stands and pinch roll stands.

Composite carbide rolls are made by combining carbide with other materials and can be further divided into carbide composite roll rings and integral carbide composite rolls. carbide composite roll rings are installed on the roll shaft, while integral carbide composite rolls have the carbide roll ring directly cast into the roll shaft, forming a single unit. The latter is applied in rolling mills with higher loads.

Performance of carbide Roll Rings: The performance of carbide rolls is influenced by the content of the bonding phase metal and the size of the tungsten carbide particles in the matrix. Different levels of bonding agent content and corresponding tungsten carbide particle sizes result in different grades of carbide. Series of carbide grades have been developed for various rolling mill stands. Tungsten carbide typically constitutes 70% to 90% of the total mass composition in carbide rolls, with an average particle size ranging from 0.2 to 14 μm. Increasing the metal bonding agent content or enlarging the tungsten carbide particle size can reduce the hardness of the carbide while enhancing its toughness. The bending strength of carbide rolls can exceed 2200 MPa, impact toughness can reach (4–6) × 106 J/m2, and the Rockwell hardness (HRA) ranges from 78 to 90.

Quality standard elements for carbide roll rings

The quality standards for tungsten carbide rolls include material porosity, WC grain size, total carbon and free carbon content, density, hardness, magnetic saturation intensity, coercivity, bending strength, impurity content, as well as the processing precision and surface roughness of the rolls. Each indicator reflects the quality of the roll and predicts its performance. Factors influencing the quality of the rolls include the dispersion, particle size, and size distribution of WC powder and Co powder in the mixture, as well as total carbon, free carbon, oxygen, iron content, etc. The type and quantity of adhesive used for molding, the temperature and time for degreasing, and the temperature, time, and atmosphere for sintering are also crucial.

Moreover, the precision of the grinding machine used for roll processing, the quality of the diamond grinding wheel, and other factors can impact the quality of the rolls. In 2009, Meetyou cemented carbide Co., Ltd. obtained ISO9001 international quality assurance system certification, ensuring the provision of high-quality and stable tungsten carbide roll ring products to customers.

New tech for WC roll rings

LGM Technology

WC roll rings undergo high temperatures, rolling stresses, thermal corrosion, and impact loads during the hot rolling process. Consequently, they exhibit poor wear resistance and are prone to fracturing during use. Building upon conventional carbide roll ring materials, we have developed a Lubrication Gradient Material (LGM) roll ring by introducing Lubrication Gradient Material (LGM), a lubrication-resistant gradient material.

This technology involves adding sulfur and oxygen to conventional carbide materials, forming stable gradient metal oxides and metal sulfides (Co3O4 and CoS, respectively) on the surface of the metal substrate. Both Co3O4 and CoS demonstrate excellent lubrication and wear resistance properties. Industrial tests of LGM roll rings have shown that the sulfides and oxides in the gradient material can reduce the friction coefficient during rolling, significantly improving the lubrication performance of the roll ring under high-temperature and high rolling force conditions. This leads to a reduction in the generation of transverse cracks, and the lifespan of LGM roll rings is 1.5 times that of conventional carbide roll rings. Moreover, it decreases the amount of grinding and the frequency of roll changes, resulting in significant economic benefits.

Cast In Carbide (CIC) Composite Carbide Roll Ring

To meet the demands of modern rolling production, a new type of carbide composite roll ring, known as Cast In Carbide (CIC) composite carbide roll ring, has been developed. This technology involves casting the carbide ring and ductile iron inner sleeve together. The connection between the roll ring and the roll shaft is key-linked. In this connection method, the outer layer of the composite roll ring, composed of carbide material with extremely high hardness and excellent wear resistance, bears the rolling force, while the inner layer, made of ductile iron with good strength and toughness, transfers torque.

The development of the Cast In Carbide (CIC) composite roll ring technology represents a new combination of powder metallurgy and casting technology. It signifies a significant advancement in the application of composite wear-resistant materials in roll rings.

Composite WC Roll Ring

This technology involves combining a carbide ring with a steel matrix containing added Ni and Cr powder through powder metallurgy. The key process involves first pressing and sintering the carbide powder into a ring, followed by molding and sintering with the selected steel matrix powder. There is a strong metallurgical connection between the carbide and the steel base. The crucial elements of this process include maintaining sintering temperatures between 1100 to 1200 ℃ and pressure conditions of 100 to 120 MPa. The sintered blanks undergo processes such as rough turning and stress relief, followed by precision turning and grinding for the final shaping.

By selecting appropriate base materials, coupled with advanced processes and proportions, it is possible to minimize residual stress between the carbide and the steel matrix in the composite roll ring.