尽管毛刺不大,但会直接影响产品质量。因此,随着各行各业对毛刺的关注,去毛刺方法层出不穷。常用的修边/去毛刺如下:

去毛刺、倒角这些小工序在工作中往往是不可小觑的,今天我们总结一下以往分享的一些资料,希望能给大家的工作带来帮助。

手工作品

传统修边刀逐渐取代了这些传统方法,无需进行技术处理,节省成本和环境保护。

化学方法

根据电化学反应原理,金属零件的去毛刺可以自动,选择性地进行。可广泛用于气动,液压,工程机械,喷油泵,汽车,发动机等行业的泵体,阀体,连杆,柱塞针阀对等金属零件的去毛刺。适用于难以去除的内部毛刺,热处理和精加工后的零件。

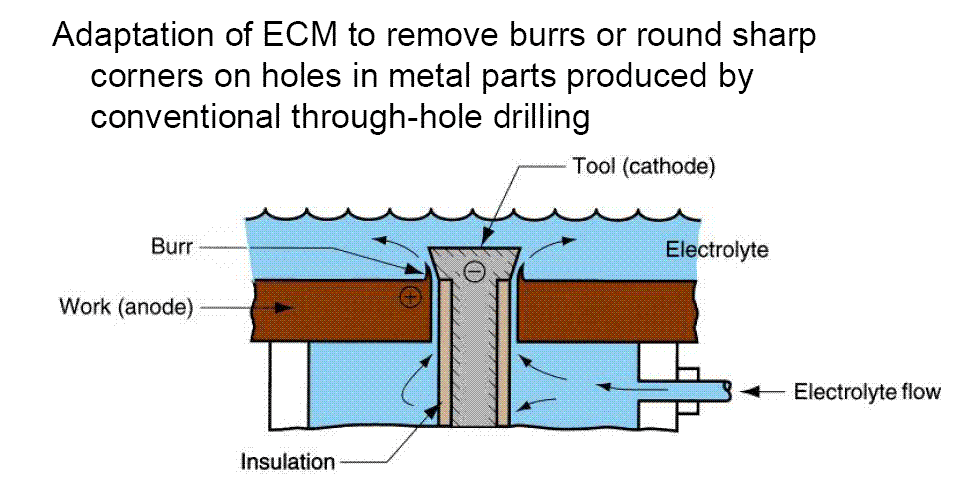

电解法

一种通过电解对金属零件进行去毛刺的电化学加工方法。将工具阴极(通常是黄铜)固定在工件的毛刺部分附近,并在它们之间留有一定的间隙(通常为0.3-1MM)。工具阴极的导电部分与毛刺边缘对齐,其他表面覆盖有绝缘层,因此电解集中在毛刺部分。在加工过程中,工具的阴极与直流电源的负极相连,工件与直流电源的正极相连。压力为0.1-0.3 MPa的低压电解液(通常为硝酸钠或氯酸钠水溶液)在工件和阴极之间流动。当连接直流电源时,毛刺将产生阳极溶解并被去除,然后被电解液带走。电解液在一定程度上具有腐蚀性。去毛刺后,应清洁工件并进行防锈处理。电解去毛刺适用于对隐藏零件中的交叉孔或复杂零件进行去毛刺。它具有很高的生产效率,仅需几秒钟到几十秒钟。该方法通常用于对齿轮,花键,连杆,阀体和曲轴油道孔进行去毛刺,以及修整尖角。缺点是零件附近的毛刺也会受到电解的影响,表面会失去原有的光泽,甚至会影响尺寸精度。

超声波法

当超声波产生的超声波能量作用于振动处于稀疏状态的液体时,会撕裂成很小的孔洞(即内部为真空)。这些孔在破裂时会产生高达数百个大气压的瞬时压力,这就是所谓的空化现象。超声波去毛刺是利用“空化现象”产生的数百个大气压的瞬时冲击力,去除附着在零件上的毛刺。超声波去毛刺并不是对所有的毛刺都适用,主要是针对一些微小的毛刺。一般如果需要用显微镜观察毛刺,我们可以尝试用超声波的方法去除。对于可见毛刺,主要取决于粘接强度。结合力较弱的毛刺可采用超声波处理。一般如果毛刺只能用刀具处理,超声波法根本就不行。超声波去毛刺的优缺点。

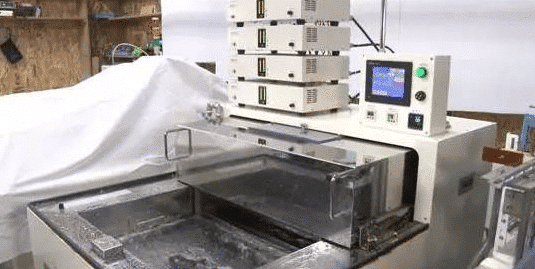

高压水喷射法

顾名思义,它以水为介质,利用瞬时冲击力去除加工后产生的毛刺和毛边,同时达到清洗的目的。经过多次测试,发现合适的压力为30mpa-50mpa。如果压力不足,则不能获得去毛刺效果。如果压力太高,可以去除毛刺,但是有损坏工件的危险。通常,液压部件在使用时承受的液压压力在20MPa以内,而毛刺残留在50MPa的压力下无法去除。在数MPa的工作压力下掉落的可能性很小,也可以认为毛刺的根部残留是工件的一部分。高压去毛刺设备的制造商越来越多,可以简单地分为两类:工件移动式和喷嘴移动式。工件移动式成本低廉,适用于简单阀体的去毛刺和清洗。缺点是喷嘴与阀体的配合度不理想,阀体内的横孔和斜孔的去毛刺效果不佳。喷嘴移动式可有效调节喷嘴与阀体之间产生毛刺的距离,通过CNC控制有效地对应于阀体内横孔,斜孔和盲孔的毛刺,但造成盲孔的毛刺由于该设备的高成本,只有汽车的心脏和工程机械的液压控制系统才能享受这种待遇。

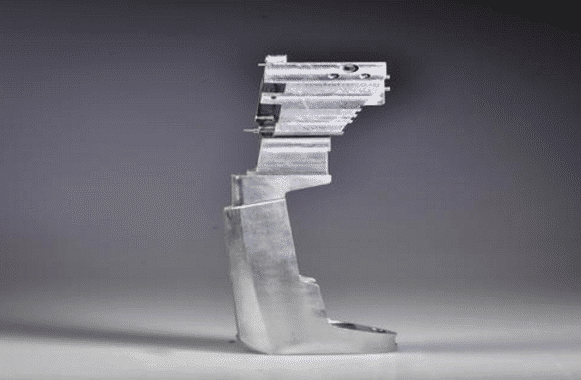

热爆炸法

又称电热去毛刺,热去毛刺被世界机械制造业公认为最适合小工件大面积去毛刺的先进技术。国内只有两家企业可以生产这种设备。它利用氢气和氧气在用于处理工件的密闭室中混合,瞬间点燃燃烧,在极短的时间内与工件表面毛刺发生剧烈的热化学反应,从而达到去除毛刺的目的.热去毛刺是一种特殊的加工技术,具有效率高、通用性强、可达性好、去毛刺均匀彻底、工件表面光洁、不受工件材料、形状和毛刺位置限制等特点。特别适用于型腔复杂、相交孔系、深孔、盲孔、螺纹孔等其他工艺方法无法解决的难于去毛刺的工件去毛刺。可用于黑色、有色金属和热塑性塑料等非金属材料的去毛刺,也可用于金属压铸件和塑料件的去毛刺。由于其加工效率高,生产直接成本低,特别适用于大规模连续生产环境。是大规模工业生产的理想高效加工设备。

冷冻修整方法

橡胶、塑料制品、锌镁铝合金等制品的飞边(或毛刺)的厚度比制品薄得多,因此飞边(或毛刺)的脆化速度比制品快。在飞边(或毛刺)为脆化而产品不脆化期间,冷冻去毛刺(修边)机通过射弹打击产品,从而去除产品处于脆化状态的飞边(或毛刺)。冷冻去毛刺(修边)机是利用液氮的超低温对橡胶、塑料制品、锌镁铝合金飞边进行快速脆化的一种。在这种状态下,高速喷出的冷冻颗粒撞击产品的毛刺(或飞边),从而既能高质量、高效地去除产品的毛刺(或飞边),又能保持产品本身的所有特殊去毛刺(修整)设备的物理性能不变。可大大提高产品的修边(去毛刺)精度,强化程度高。该类设备已成为精密橡塑制品和压铸企业精加工去毛刺必不可少的设备。

磁力法

电磁去毛刺机利用其独特的磁场分布产生强大而稳定的磁感应效果,从而使电磁钢针(进口原材料。半永久性)和工件可以在各个方向和多个角度完全磨削,从而实现快速除锈,死角去除,去毛刺和切削刃去除,氧化膜去除和烧结痕迹去除的功能。特别是对于形状复杂,有孔接缝,内外螺纹等工件,可以表现出魔幻和魔幻效果,并且不会损坏工件表面,不会影响工件的精度。让工件立即变得光滑整洁,焕然一新。它适用于金属零件(例如金,银,铜,铝,锌,镁,铁,不锈钢)和非金属零件(例如硬塑料)的研磨,抛光和去毛刺。

机械手方法

它是典型的机电一体化设备,它综合利用了机械与精密机械,微电子与计算机,自动控制与驱动,传感器与信息处理,人工智能等学科的最新研究成果。随着经济的发展和各行各业对自动化要求的提高,去毛刺机械手技术得到了飞速发展,并出现了各种去毛刺机械手产品。去毛刺机械手的实用性不仅解决了许多仅靠人力难以解决的实际问题,而且促进了工业自动化的进程。

去毛刺机械手的典型零件有:铝制轮毂,变频器壳体,同步器壳体,同步器齿轮轮毂,轴承盖,气缸体,阀体,阀盖,输出轴,发动机齿轮等。

自动去毛刺磨刷

纤维刷可以承受高达150°C的工作温度。即使没有冷却液,它也可以工作。另外,研磨刷具有很强的耐水性,不会受到冷却液的影响。它可以去除工件的毛刺,特别是对于薄工件和边缘的工件。

表面研磨:管道,接头和轴的研磨。冲压或激光加工过程中的内孔毛刺可用磨刷去除,以使汽车精密金属零件的多个边缘无毛刺。