家用电器与人们的日常生活息息相关,如家用空调、家用空调、冰箱、洗衣机、家用厨房电器、家用美容电器、家用卫浴电器等,2019年累计主营业务收入1 -8家电业实现1.05万亿元,同比增长4.7%,累计实现利润总额798.97亿元,同比增长14.9%。各类产品均保持增长态势。家用电器中有一个不可或缺的零件,就是粉末冶金零件:烧结金属含油轴承和烧结金属机械结构件。

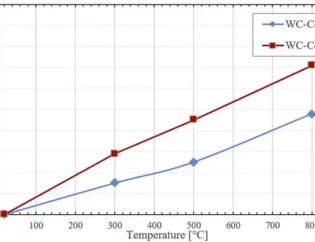

根据中国机械学会粉末冶金协会的统计,2018年粉末冶金零件累计主营业务收入7.03亿元,累计利润总额82966万元,累计销量19万吨,其中1176.86亿元,家电行业累计销售量40998吨。图1显示了2019年1月至2019年9月P / M零件的累计主营业务收入和销售量。以上数据表明,在当前经济形势下,P / M行业仍在逆势而上,并找到了活力。在困难中,家用电器行业的P / M部分占总量的16.7%,销量占20.6%,而家用电器行业的P / M部分也是重要的部分P / M行业。

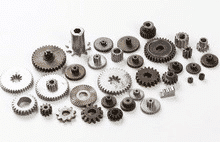

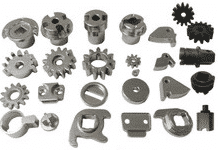

粉末冶金是一种节约材料和节能的技术。可用于制造具有特殊性能的家用电器。作为家用电器生产和消费的大国,中国和世界范围内用于家用电器的PM产品的数量和质量存在很大差距。为了增加粉末冶金材料在家用电器中的应用和发展,摆在我们面前的任务艰巨。在空调压缩机中,粉末冶金家用电器的零件主要包括:缸体,下缸盖,上缸盖等;在洗衣机中,它们主要包括:各种轴承,变速齿轮,中心齿轮,行星齿轮减速器等;在冰箱压缩机中,主要包括:连杆,活塞,阀板,底阀座等。在空调中,它们主要包括:传动齿轮,各种轴承等。

粉末冶金在家用电器领域的发展

在家用电器的发展中,粉末冶金的初期主要是制造含铜的含油油。压缩机缸盖,高精度,复杂形状的缸套等难加工零件,以及一些具有特殊性能要求的产品也已成功开发。在中国,各种压缩机对PM结构件的需求非常大。例如,用于空调和冰箱的旋转压缩机的年产量约为355万,每台压缩机需要80-350g的PM结构件。冰箱用连杆压缩机的年产量约为827万,每台需要100g P / M结构件;用于空调和冰箱的滑杆压缩机的年产量约为310万,每台需要30-200g的P / M结构部件。家用电气产品是P / M结构零件的大市场,但是这些零件不仅形状复杂,而且还要求耐高温高压,防锈,气密性和良好的机械加工性。对于P / M制造商来说,进一步提高技术设备和设计水平也非常有益。

粉末冶金在家用电器中的应用

为了降低噪音,在洗衣机和电风扇电动机中已经使用了PM轴承,特别是低噪音的铁基轴承,可以代替铜。整个机器的噪音为〜40dB PM轴承。由于其自润滑,低噪音,低价格,适合批量生产,因此PM精密含油轴承也广泛用于相机,录音机和其他微型电器。

P / M不锈钢结构零件,例如304L P / M材料制成的自动洗碗机和洗衣机的零件,316L P / M材料制成的冰箱制冰机的推出板,限位开关和410L P / M制造的离合器材料等粉末冶金铜基合金广泛用于洗碗机,干衣机,洗衣机,缝纫机,吸尘器,冰箱,食品搅拌机风扇等。

目前洗衣机行业主要是全自动洗衣机。市场上销售的全自动洗衣机一般分为三类:欧洲发明的前端侧开式滚筒洗衣机、亚洲人发明的波轮顶开式洗衣机、中国发明的“搅拌式”洗衣机北美。中间使用了很多粉末冶金零件,部分钢制零件改为粉末冶金零件,例如美国通用电气公司在“搅拌式”全自动洗衣机的变速箱中重新设计了两个钢制零件:锁管和将管旋压成粉末冶金件,提高了生产成本和产品质量,降低了生产材料成本、人工成本、管理成本和废料损失,每年节约25万美元以上。

目前,中国家电已进入平稳发展阶段。家用电器及其材料的质量越来越重要,尤其是广泛应用于家用电器的粉末冶金材料。因为,有些家电材料和零件只能用粉末冶金制造,如冰箱压缩机、洗衣机、电风扇等的多孔自润滑轴承;一些家电材料和零件采用粉末冶金制成,质量更好,价格更低,例如家用空调和吸尘器的排气扇中的复杂形状齿轮和磁铁等。此外,粉末冶金在维护方面发挥着重要作用生态,保护环境,节约材料和能源。