低合金结构钢是指合金总成分小于5%的合金结构钢。这种钢的碳含量类似于低碳钢,并且主要通过少量合金元素来增强其碳含量,以提高韧性和可焊性。它的强度远高于相同的碳素钢。广泛用于压力容器,化工设备,锅炉,桥梁,车辆,船舶和大型钢结构。锰,硅和钼等合金元素会导致固溶强化。钒和铌可以细化晶粒并提高韧性。钼可以改善淬透性,贝氏体组织和热强度。

品牌及其代表

低合金结构钢牌号及其表达:我国低合金结构钢有五个牌号,主要元素为锰、硅、钒、钛、尖、铬、镍和稀土元素。其商标由屈服点字母Q、屈服点值和质量等级(A、B、C、D、e级)组成。分为五个等级,分别表示为:屈服点等级——品质等级。屈服点等级:q295、Q345、Q390、Q420、Q460。

性能要求

1.良好的综合机械性能。普通的低合金结构钢起初应具有较高的屈服极限,但由于其工作条件的复杂性,还应具有良好的综合力学性能。例如,它可以承受使用中的各种应力(例如温差应力,交替疲劳载荷产生的应力等)的影响,并且可以承受加工过程中的剪切,冷弯,焊接等加工程序。制造过程,以及由此产生的老化脆性。

2.良好的工艺性能。要求普通的低合金钢应具有良好的加工成型性能,并采用剪切,冲压,热弯,焊接等常用方法制造出优质的成品。对于锅炉,压力容器,钢结构等,一般采用焊接方法,因此钢应具有良好的火焰切割性能和焊接性能,焊缝附近热影响区的性能变化较小,焊缝及其部位相邻区域不得产生裂纹,且焊接接头的综合机械性能不得小于(或很少小于)母材。另外,要求钢具有良好的冷冲压性能。

3.良好的耐腐蚀性。由于普通低合金钢及其强度远高于碳钢,并且压力容器和由其制成的钢结构的壁厚比碳钢小,因此大气腐蚀(尤其是海洋大气腐蚀)造成的损失率因此,必须提高其抗腐蚀能力,以便在各种大气条件下具有良好的抗腐蚀能力。因此,不仅应在实验室中而且还要在现场进行钢的耐蚀性测试。当然,对于碳素钢,低合金钢和其他材料,必须采用适当的外部防腐技术。

合金元素的作用

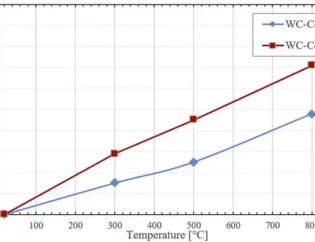

压力容器中广泛使用的普通低合金钢多为铁素体珠光体组织。最终性能通过热轧或正火获得,其组织为钢的平衡组织所接受。钢中的主要合金元素是碳。增加碳含量可以增加珠光体的数量,提高屈服极限和强度极限。但增加碳含量有一定的限度,因为碳含量的增加会影响钢的焊接性能和其他性能(如冲压性能等),使脆性转变温度升高,冷脆性增加。变坏了。因此,压力容器用低合金结构钢的含碳量一般限制在0.20%以下。在碳含量有限的情况下,这种钢强度的提高主要依靠少量各种合金元素的添加(总添加量小于5%,一般小于3%,多为1%-2%)。对于铁素体珠光体组织的低合金结构钢,添加合金元素对其强度的影响如下:

①相同溶液强化铁素体;

②增加珠光体的相对含量;

③控制晶粒尺寸;

④影响珠光体的分散;

⑤沉淀硬化。

锰和硅都固溶于铁素体中,具有明显的固溶强化作用。其他元素包括铬,镍,铜,钴等。考虑到节省成本和节约资源的条件,锰和硅是中国低合金钢中常用的合金元素。在低碳的条件下,当锰含量小于1.8%时,不仅可以提高钢的强度,而且可以保持可塑性和韧性。另外,锰可以扩大奥氏体区并使钢的共析点向左和向下移动,从而使它具有更多的珠光体组织和更细的结构,并相应地提高了钢的强度。

低合金结构钢中的硅含量一般在0.2%-1.7%范围内,会降低韧性。铬和镍也是铁素体的固溶强化元素,镍对提高低温韧性有很好的作用;磷强化铁素体效果显着,但由于冷脆性增加,最高含量应限制在0.15%,磷和碳的总含量应限制在0.25%以下。

应用

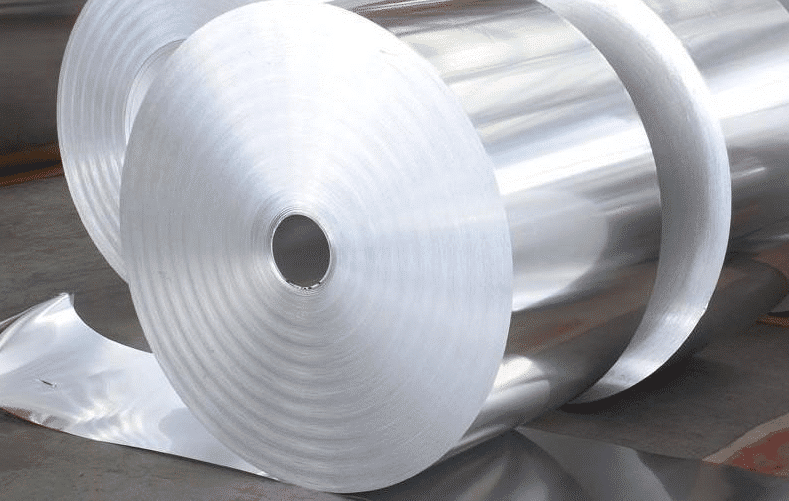

根据国家标准(低合金高强度结构钢)(GB 1591),规定了每种等级的低合金高强度结构钢的化学成分和力学性能。低合金结构钢由于合金元素的强化作用,不仅具有较高的强度,而且具有较好的可塑性,韧性和可焊性。 Q345钢具有良好的综合性能,是钢结构的通用品牌。 Q390等级也是推荐的品牌。与碳素结构钢Q235相比,低合金高强度结构钢可以节省20%〜30%钢,并具有良好的动载荷和抗疲劳性。低合金结构钢主要用于轧制各种型材,钢板,钢管和钢筋。它广泛用于钢结构和钢筋混凝土结构,尤其是各种重型结构,大跨度结构,高层结构和桥梁工程,承受动态和冲击载荷的结构等。

低合金结构钢是一种低碳结构钢。合金元素含量小于3%,主要用于细化晶粒,提高强度。这种钢的强度明显高于相同碳含量的碳钢,因此通常被称为低合金高强度钢。它还具有良好的韧性,可塑性,可焊接性和耐腐蚀性。最初用于桥梁,车辆,轮船等行业,其应用范围已扩展到锅炉,高压容器,油管,大型钢结构,汽车,拖拉机,土方机械等产品。