good mechanical process engineer must be a good processing equipment application engineer. He has a very accurate and full understanding of the types, processing application scope, structural characteristics and processing accuracy of various processing equipment in the machinery industry. At the same time, he can also actually combine the specific conditions of his company’s equipment, Make reasonable equipment layout and arrangement for various processing parts and processes, understand their processing advantages and disadvantages, and be able to make good use of their strengths and avoid weaknesses to coordinate the company’s machining work.

下面,我们就对机械加工行业常用的几种加工设备做一个大致的分析和认识,以便我们从感性的角度对这个行业的加工设备有一个比较清晰和清晰的定义。同时,我们也可以从理论的角度对各种加工设备进行一定的分析,以便我们在以后的工作中更好地结合实际,从而进一步指导我们的工作,帮助我们的工作。

Our introduction focuses on the most common machining equipment in the machining industry, such as turning, milling, planing, grinding, boring, drilling, wire cutting and so on. We further elaborate on the type, scope of application, structural characteristics and machining accuracy of these machining equipment. Let’s move on to the main topic below.

1.车床![您熟悉这些不同的加工方法吗? 2 您熟悉这些不同的加工方法吗? 2]()

(1) 车床类型

There are many types of lathes. According to the statistics of a machinist’s manual, there are 77 kinds. The typical categories are: instrument lathes, single axle automatic lathes, multi axle automatic or semi-automatic lathes, return wheel or turret lathes, crankshaft and camshaft lathes, vertical lathes, landing and horizontal lathes, profiling and multi tool lathes, axle roller spindles and tooth shoveling lathes, etc, This is divided into many small categories, and the number varies. Vertical lathes and horizontal lathes are commonly used in our machinery industry. These two lathes can be seen in almost all places with machining.

(2)车床加工范围

我们主要选取几种典型的车床类型来介绍加工的应用范围。

A、卧式车床可用于车削内外圆柱面、圆锥面、成形旋转面和环形槽、车削断面和各种螺纹,并可进行钻孔、铰孔、铰孔、攻丝、螺纹和滚花。普通卧式车床虽然自动化程度低,加工过程中的辅助时间较多,但由于加工范围广,综合性能好,在机械加工行业得到了广泛的应用和推广。是我国机械行业典型的加工设备之一,也是机械加工行业不可缺少的加工设备之一。

B、立式车床适用于各种框架、壳体零件的加工,以及各种零件的内外圆柱面、圆锥面、端面、槽、切、钻、扩、铰等加工。借助附加装置,还可实现螺纹车削、端面车削、仿形、铣削、磨削等加工工艺。

(3) 车床加工精度

A、一般卧式车床的加工精度如下:

圆度:0.015mm;圆柱度:0.02/150mm;平面度0.02/¢150mm;表面粗糙度:1.6ra/ μ m。

B、立式车床加工精度如下:

圆度:0.02mm;圆柱度:0.01mm;平面度 0.03mm。

以上加工精度只是一个相对参考值,并不代表所有车床都符合要求。很多车床设备根据厂家的具体要求和具体的装配条件,都有一定的上下浮动量。但是,无论浮动量有多大,其加工精度值都必须满足该类设备的国家标准要求。采购此类设备时,如加工精度不符合国家标准要求,采购人有权拒绝验收和付款。

2.铣床

(1)铣床类型

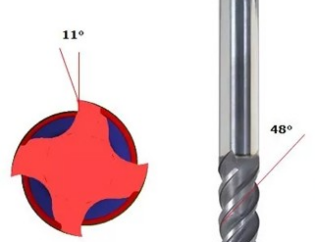

铣床的类型也复杂多样。据机械师手册统计,有70多种。典型类型有:仪表铣床、悬臂滑枕铣床、龙门铣床、平面铣床、仿形铣床、立式升降铣床、卧式升降工作台铣床、床身铣床、刀具铣床等,分为很多小类,数量不同,在我们的机械行业中,常用的有立式加工中心和龙门加工中心。几乎所有的加工场所都可以看到这两种铣床。我们还对这两种典型的铣床进行了一般性的介绍和分析。

(2)铣床适用范围

由于铣床的种类和结构太多,应用范围很广,所以我们对两种典型的铣床进行简单的介绍,它们是最常用的立式加工中心和龙门加工中心。

A、立式加工中心(如上图),实际上是一种带刀架的立式数控铣床,主要特点是使用多刃旋转刀具进行切削,可用于加工平面、槽、齿轮分度件、螺旋面及各种面。特别是随着数控技术的应用,这类机床的加工范围也有了很大的提高,除了可以进行各种铣削加工外,还可以对工件进行钻孔、镗孔、铰孔和攻丝,具有广泛的实用性和通用性。意义。

B. Gantry machining center, compared with vertical machining center, is a composite application of CNC gantry milling machine tool adding library. In the processing scope, gantry machining center has almost all processing capabilities of ordinary vertical machining center, and can adapt to the processing of larger tools in terms of the overall dimension of parts, At the same time, it has great advantages in processing efficiency and precision, especially the practical application of five axis linkage gantry machining center, its processing scope has also been greatly improved, which lays the foundation for the development of China’s manufacturing industry to the direction of high precision.

(3)铣床加工精度:

A、立式加工中心:

平整度:0.025/300mm;粗糙度:1.6ra/μm。

B、龙门加工中心:

平整度:0.025/300mm;粗糙度:2.5ra/ μ m。

以上加工精度只是一个相对参考值,并不代表所有铣床都符合要求。许多铣床设备根据制造商的具体要求和具体的装配条件,都有一定的上下浮动。但是,无论浮动量有多大,加工精度值都必须符合该设备的国家标准要求,如果购买的设备,如果加工精度不符合国家标准的要求,购买方有拒绝接受和付款的权利。

3.刨床![您熟悉这些不同的加工方法吗? 5 您熟悉这些不同的加工方法吗? 5]()

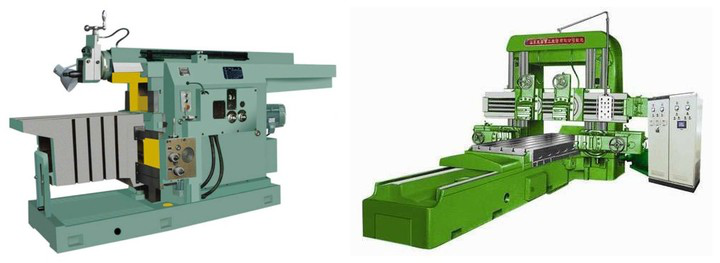

(1) 刨床类型

Compared with lathes and milling machines, there are many fewer types of planers. Similarly, according to the statistics of the machinist’s manual, there are about 21 types. The typical types are: cantilever planer, gantry planer, shaper, edge and die planer, etc. these categories are divided into many small types of planer products, and we have the highest utilization rate in the machinery industry, The most popular planers should be shapers and planers. As shown in the figure above, we will make a basic analysis and introduction for these two typical planers.

(2)刨床的应用范围

刨床的刨削运动主要是相对于被加工工件作周期性的往复直线运动。其适用的刨削零件特点多为平面、斜面、凹凸面的加工,也可对各种曲面进行刨削。但由于自身加工特性的限制,加工刨削速度并不太高,带回程的刨床不参与零件的加工切削,因此造成空行程损失,处理效率比较低。

同时,随着数控技术的巨大进步和其他加工设备的自动化,刨削加工方式逐渐被取代。从很多设备的升级趋势来看,这类加工机床并没有大幅度的升级和创新,很大程度上还停留在原有的结构布局上,尤其是立式加工中心和龙门加工中心的蓬勃发展,以及加工工具的不断创新,在加工范围方面大大取代了刨床的加工优势,使得这种加工效率相对较低的设备处于非常尴尬的境地。

(3)刨床加工精度

The planing accuracy can generally reach the it10-it7 accuracy level, especially for the machining of long guide rail surface of some large machine tools, it can even replace grinding, which is the so-called “precision planing instead of precision grinding”.

4.磨床![您熟悉这些不同的加工方法吗? 7 您熟悉这些不同的加工方法吗? 7]()

(1) 磨床类型

Compared with the processing equipment of the previous models, there are many kinds of grinding machines. According to the statistics of a machining technologist’s manual, there are about 194 kinds, which can be divided into: instrument grinder, cylindrical grinder, internal grinder, grinder, coordinate grinder, guide rail grinder, tool edge grinder, plane and end face grinder, crankshaft camshaft spline and roll grinder Tool grinder, superfinishing machine, inner circle honing machine, outer circle and other honing machines, polishing machine, abrasive belt polishing and grinding machine. There are too many types of machine tools, such as grinding machine tools, piston ring grinding machines, roller grinding machines, ball grinding machines and grinding rings for grinding pistons, valves, rollers, etc, Moreover, many grinding machines are some specific equipment in specific industries, so we make a basic introduction to the grinding machines commonly used in the machinery industry. In this article, we mainly choose cylindrical grinding machines and surface grinding machines for a brief description.

(二)磨床适用范围

A、外圆磨床和外圆磨床主要用于加工圆柱面、圆锥面或其他旋转体的外表面和台肩端面。因其良好的加工适应性和加工精度,被广泛应用于机械加工中一些高精度零件的加工,特别是在这些零件的最终精加工过程中,不仅能最大程度地保证加工零件的几何尺寸。程度,也能满足良好的表面光洁度要求。因此,它是机械加工过程中不可缺少的设备之一。

B、平面磨床主要用于加工平面、台阶面、侧面等零件的表面。它也广泛用于机械工业。尤其是在一些高精度零件的加工中,磨床几乎是保证加工精度的唯一选择。因此,平面磨床的使用是大多数磨削操作人员的必修课,即使在一些设备装配行业,平面磨床的使用也是装配人员的标准技能,因为装配过程中各种调整垫的磨削取决于平面磨床。

(3)磨床加工精度

A、外圆磨床加工精度:

圆度和圆柱度:0.003mm;表面粗糙度:0.32ra/ μ m。

B、平面磨床加工精度:

平行度:0.01/300mm;表面粗糙度:0.8ra/ μ m。

从以上加工精度我们也可以清楚地看出,与以往的车床、铣床、刨床等加工设备相比,磨床可以达到更高的行为公差精度和表面粗糙度。因此,磨床在许多零件的精加工工序中得到广泛而广泛的应用。

5、镗床![您熟悉这些不同的加工方法吗? 9 您熟悉这些不同的加工方法吗? 9]()

(1) 镗床型

与前几类加工设备相比,镗床也是数量相对较少的加工设备。据机械师手册统计,大约有23种。可分为以下几类:深孔镗床、坐标镗床、立式镗床、卧式铣镗床、精密镗床、拖拉机维修镗床等,我们的机械行业应该飞坐标镗床。下面我们也对坐标镗床的一些特点做一个简单的介绍和分析。

(2)镗床适用范围

有许多类型的钻孔机。我们将简要介绍坐标镗床。我们可以据此学习其他类型的钻孔机知识。三坐标镗床是一种带有精密坐标定位装置的精密机床,主要用于对尺寸、形状和位置精度要求较高的孔系统的镗削加工。可用于钻孔、铰孔、铰孔、端面、切槽铣削表面,也可用于坐标测量、精密标尺和标记,具有非常广泛和可靠的加工特性。

But with the development of CNC technology, especially the development of CNC vertical milling machine and NC horizontal milling machine, boring machine, once the dominant machine in hole system processing equipment, has the risk of being replaced gradually. Of course, it has an irreplaceable objective side. However, the extinction or development of any equipment is a progress for the machining industry, It is the progress of technology, the progress of technology, and the progress of our country’s manufacturing industry.

(3)镗床加工精度

三坐标镗床孔径精度为6-7,表面粗糙度为0.4-0.8ra/μm。

But boring machine processing has a very bad place, especially when processing cast iron parts, it is called a dirty ah, a white faced young student goes in, a zhangfei Li Kui jumps out, there is a boring machine, a sense of non-existent, so based on such a practical reason of processing link, the possibility of this equipment will be replaced in the future is also increasing, Because who doesn’t care about their face? As soon as possible, many people don’t, but we need to pretend we have a lot of appearance.

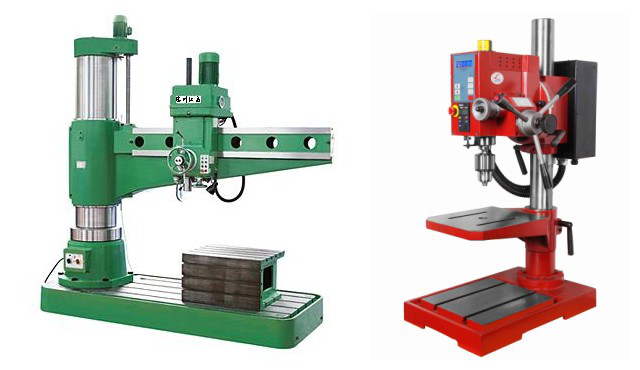

6.钻孔机

(1) 钻床类型

This is the most widely used processing equipment in the machinery industry. If it is a machining factory, it will basically have one. If you don’t even have this processing equipment, you are embarrassed to say that you are dry processing. According to the statistics of a machining technologist’s manual, there are about 38 kinds, which can be divided into the following categories: coordinate boring and drilling machine, deep hole drilling machine, rocker drilling machine Table drilling machine, vertical drilling machine, horizontal drilling machine, milling drilling machine, center hole drilling machine, etc. the most common one we use in the machinery industry is the radial drilling machine, which is only the standard configuration of our machinery processing industry. Without this equipment, you basically can’t do this industry. That’s why we’ll focus on introducing this kind of drilling machine next.

(2)钻床加工范围

我们主要说的是摇臂钻。对于这种机床,我这里只有一句话,就是钻各种类型的孔。除钻孔外,还可实现铰孔、铰孔、钻孔、攻丝等加工工艺。但是它有一个很大的问题,就是孔系统的定位精度不高,所以对于一些对孔系统定位精度要求较高的零件,我们通常不会选择钻床来实现。

(3)钻床加工精度

Slightly….. Because there is basically no machining accuracy, just drilling a hole.

7、线切割![您熟悉这些不同的加工方法吗? 13 您熟悉这些不同的加工方法吗? 13]()

As for the processing equipment of wire cutting, I haven’t had much contact with it, so I haven’t accumulated much in this field and haven’t done a lot of homework. Therefore, I have some limitations in the scope of use in the machinery industry, but it also has its unique existence value, especially for the blanking and processing of some special-shaped parts, However, in view of its low processing efficiency and the vigorous development of laser machine, wire cutting processing equipment is also gradually walking on the edge of the eliminated industry.

In fact, my company has a large number of wire cutting equipment, but because it is actually a blanking process, I don’t pay much attention to this equipment. My overall impression is “dirty, slow and annoying”. Many operators are unwilling to operate this equipment, especially with the vigorous application of various numerical control equipment and the gradual maturity of automation technology, The advantages of this equipment have been a little “gone”. Of course, it will continue to exist within a certain time and scope, which is certainly inevitable, but I also believe that its value will be smaller and smaller.

就个人而言,我很高兴看到这种设备的消亡,因为它在加工效率或工作环境方面都没有优势。

注:本文建议收藏。虽然在知识上没有什么创新,是一些行业基础知识的汇编,但是我在文章的结构和设计,以及相关图片的选取和处理上,都做了很用心,并且描述了结合行业的具体做法。对于机械行业的从业者,尤其是新机械工艺师具有很好的借鉴和参考价值。