What is a Carbide End Mill?

In its most basic sense, a carbide end mill is a cutting tool that can be used for a wide range of industrial milling operations. It will commonly be used in lathes and similar resources used for metalwork cutting and applications.

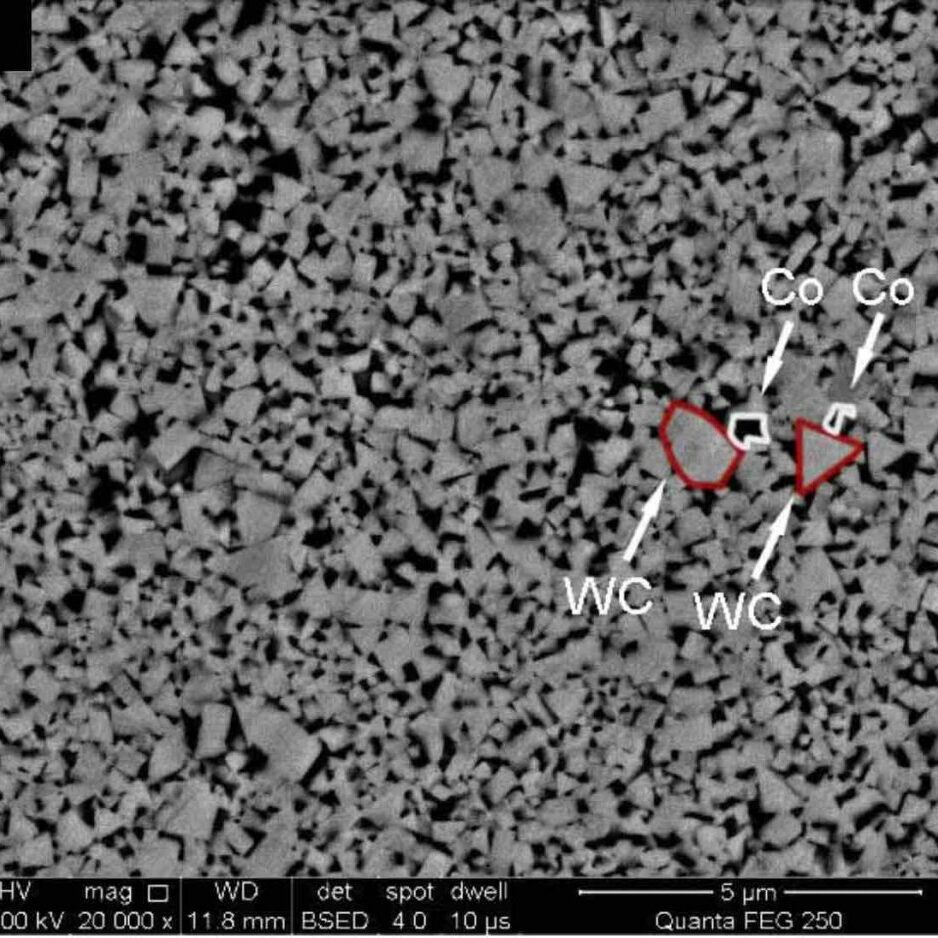

Carbide end mills are, unsurprisingly, made from a compound of carbide and cobalt. While they may look like drill bits at a glance, they offer a far better function as they can move in all directions (unlike a standard drill bit). This makes them particularly ideal for a range of geometric cutting tasks, and are often used on aluminium.

They fit into a lathe in a straightforward fashion and offer a reliable performance even under high heat and pressure. They may be used to create a variety of grooves, slots, and pockets in the workpiece.

As one of the top carbide end mills manufacturers in China, Meetyou Carbide produces and stocks all kinds of standard high-performance solid carbide end mills for steel, aluminum, stainless steel, etc. OEM and special tools are also provided.

What is CNC milling?

CNC milling is a process that uses computer numerical control to cut a workpiece using rotating cutting tools like end mills. The tool is attached to a platform, which moves the material to meet the tool. The CNC mill operator programs the cut to achieve the desired result. This computer software can even allow the user to view a 3D rendering of the finished product.

Difference Between Milling and Drilling

In short, milling uses the vertical movement of a mill cutter and the horizontal movement of the workpiece to cut the material while drilling uses vertical motions with a rotating drill bit to create holes in the workpiece. And here is the full post.

Why Choose Carbide End Mills?

First and foremost, the fact that an increasing number of mould shops and applications are choosing aluminium over traditional steel materials has resulted in a significant spike in popularity for carbide end mills.

Aluminium has soft properties, meaning that very specific geometries and characteristics are needed to gain reliable results. This makes carbide end mills the perfect tool for the job.

Carbide end mills ultimately save time and money. When using the correct cutting geometries and coatings, mould finishing times are significantly reduced as achieving finishes of 16µ and above becomes far easier. Likewise, metal removals can become up to five times faster.

The wide range of geometries and angles also leaves the user with immense versatility and control. From indexable end mills to helical cutting edges, those tools can be used to create a wide range of finishes.

When working in the metalwork arena, the choice of cutting materials is one of the greatest decisions you’ll face as the selections will influence everything about the final outcome.

Choosing

The Right Carbide End Mill

Top China Carbide End Mills

When choosing the right carbide end mills for your applications, there are several factors to consider. These include the critical angles (end cutting edge angle, axial relief angle, radial relief angle, and radial rake angle) and length and finish of the flutes.

Meetyou Carbide takes great pride in providing a wide range of carbide end mills. The extensive catalog includes:

|

|

|

|

|

|

| MD | General Economy | Below HRC45 | HRC50 | AlTiN-based | grey |

| MG | General Purpose | Below HRC45 | HRC50 | AlTiN-based | grey |

| MP | High hardness | Below HRC55 | HRC60 | AlCrN-based | light grey |

| MH | Extremely High Hardness | Below HRC60 | HRC65 | AlTiN/TiSiXN | bronze |

| MC | Extremely Economy | Below HRC45 | HRC50 | TiSiN | bronze |

| SUS | Stainless Steel | Finishing | Roughing | AlCrN/SiN | blue grey |

| AL | Aluminum | Aluminum | Aluminum | None | None |

Also, we can provide cut-to-length h6 polished carbide rods(cutting tool blanks) for end mills manufacturing.

Whether you know exactly what type of carbide end mill is required or need to discuss the options with an expert, we are here to help.

Our

Advantages

Thanks to our premium quality carbide rod made from Germany H.C.Starck powder, we take the first lead over others.

Advanced CNC Grinders

Advanced CNC five-axis CNC grinders from ANCA, Rollmantic and Walter to ensure the accuracy.

Multilayered nano PVD coatings are applied to strengthen our end mills cutting competence.

Ready to find out more?

Email us today for more information!