Cylindrical

Tungsten Carbide Rotary Burr

Tungsten carbide rotary burrs are small cutting tools used in grinding, shaping, and de-burring for materials like ceramics, stone, steel, aluminum, plastics, and hardwood. It offers a high stock removal rate with a smooth milling action to reduce vibration and noise. And it delivers large and good chip removal.

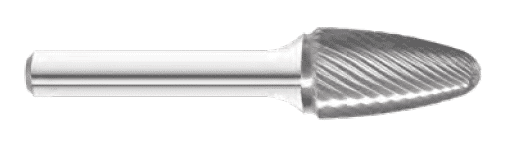

Single Cut

Single cut carbide burr is a general-purpose tool designed for cast iron, steel, some copper and brass, and other ferrous materials. It will give good material removal and a good workpiece finish.

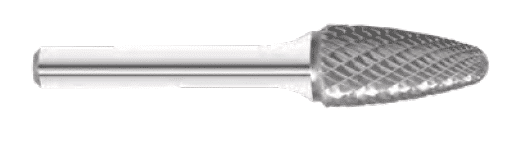

Double Cut

The double-cut allows for rapid stock removal in harder materials. The addition of the left-hand flutes reduces the pulling action, which allows for better operator control. It reduces the size of the chips, and it can be used at slower than normal speeds.

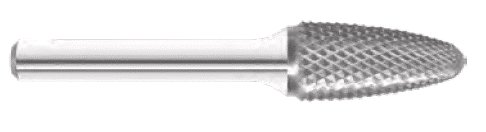

Diamond Cut

The diamond cut is very effective in heat treated and tough alloy steels, producing extremely small chips. It offers very good operator control with good stock removal at the sacrifice of finish. The diamond grind will reduce tool life.

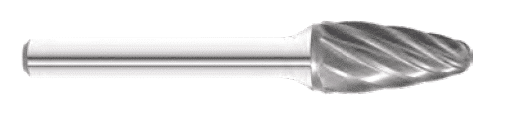

Fast Mill Cut

For use on non-ferrous and non-metallic materials. It is designed for rapid stock removal with minimum chip loading.

Industry

Applications

- Long life

- Use for long production runs

- High stock removal

- Ideal for using on many hard and tough materials

- Ideal for Deburring, finishing, carving, shaping and smoothing welds, molds, dies and forgings

Thanks to the excellent hardness of the tungsten carbide, they are very suited to be used on most hard materials, such as steel, non-ferrous metal alloy, cast iron, and reinforced plastics. With tungsten carbide, you can run your burr bits in a hotter environment, in which HSS burrs will start to melt.

- Steel, Carbon Steel & Stainless Steel

- Cast Iron

- Aluminum

- Titanium

- Cobalt

- Nickel

- Gold, Platinum & Silver

- Ceramics

- Fiberglass

- Plastic, Carbon Fiber Reinforced Plastic (CRP), Glass Fibre Reinforced Plastic (GRP)

- Brass, Copper & Bronze

- Zinc

- Wood

Carbide burrs are found in tools such asdie grinders, pneumatic rotary tools, high-speed engravers, micro Motors, pendant Drills, and flexible shafts, and hobby rotary tools. They are ideal for metalworking, tool making, wood carving, jewelry making, welding, chamfering, casting, deburring, grinding, cylinder head porting, and sculpting in the aerospace, automotive, dentistry, stone, and metalsmith industries.

Burrs

Shapes

Use for rounding off edges and making concave cuts. Use the pointed end for cutting in hard to reach areas and acute-angled contours.

Use inverted cone-shaped tungsten carbide burrs for making v-cuts and rear side chamfering.