Infinite Possibilities

The applications of tungsten carbide that follow are about nearly every aspect of the manufacturing industry, from metal cutting to woodworking, oil&gas to mining, mold to PCB, and more.With an innovative approach to continuously reinforce your productivity, we lead the tungsten carbide industry for more than 20 years.

We manufacture all kinds of carbide woodworking tools, including unground carbide flat bar blanks for Solid Carbide Strips, Saw tips for circular blades, Indexable knives, Blanks for profiling, and rods for woodworking, etc.

Tungsten carbide has proven to be the metal alloy above all others that possesses the physical properties, versatility, and usefulness to stand up to the needs of healthcare professionals across the world.

Meetyou Carbide’s hardmetal components deliver exceptional performance under challenging conditions. Our carbide dies can provide high wear resistance and extraordinary long lifetime for wire drawing and cold heading industries.

Our replaceable rotor knife for shredder machines and size reduction machinery can help you to recycle all kinds of materials like rubber, plastic and general waste. Our rotary blade can be used in shredder machines like ZERMA ZTS Tyre shredder.

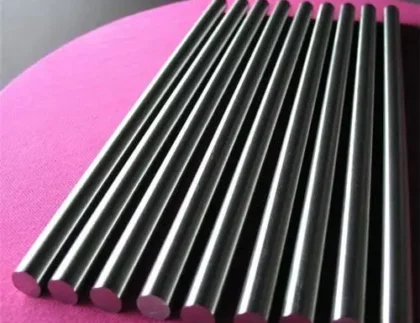

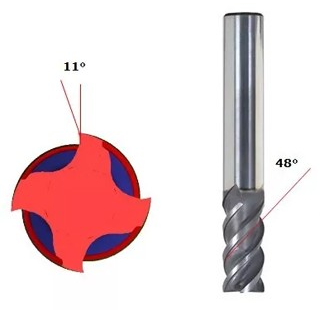

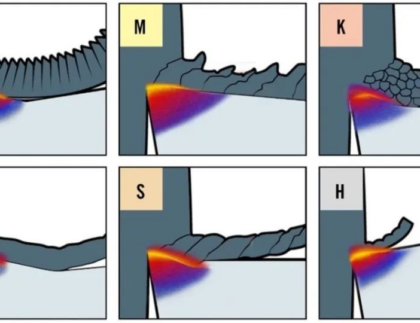

Meetyou Carbide is particularly experienced in developing and producing metal cutting tools, especially carbide rods which is the tool material for cutting tools like end mills and drills. Other metals cutting inserts blanks and cutting knives are also manufactured for high-performance metal cutting applications.

Meetyou Carbide is one of the best suppliers to the oil and gas industries. In order to be used in the hostile subsea engineering environment, tungsten carbide is used to manufacture extremely hard wearing components such as control valves, liners and bearing housings for use in exploration and flow control applications.

3C industry requires a long-lasting and reliable material in the manufacturing and installation of the various parts. Tungsten Carbide is providing a material that is changing the way the 3C industry produces parts.

Meetyou Carbide’s numerous types of carbide buttons are used for multiple applications, like carbide buttons for road building, snow plow inserts for removing snow and mining sphere buttons for drilling. We help you to carve the path of sucess

Let us

Be your partner

ISO Certificated in design, manufacturing carbide tools, we provide services more than just supplying the tools but also all the professional knowledge about the application and research development. Our love and passion for innovation and determination helped us to carve out a path of success.

◎ ISO9001 Certified

◎ Dedicated research team

◎ Outstanding raw material

◎ Advanced machines

Quality First

Since its foundation, Meetyou Carbide has always been focusing on the quality of products along with our belved customers’satisfaction.

Solutions for your industry?

Email us today for a free quote!