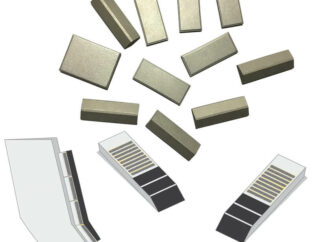

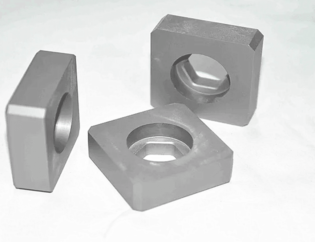

Tungsten Carbide Plate

Tungsten carbide plates are also named as tungsten carbide sheets, square plates, flat stock, and flat bars. They are made from tungsten carbide, which is harder than many materials in terms of corrosion resistance and wear resistance. So they can be used in woodworking, metal machining, and molding industry. All our carbide plates have been stress-relieving HIP sintered in order to gain resistance to corrosion, pitting and cracking commonly experienced during machining.

Sintering

HIP.

The advanced computer-controlled HIP furnaces are applied to provide more pressure during the sintering process in order to get denser structure.

Powder

Excellent.

We carefully select and control the excellent quality of our raw powders. Powder spray drying technology ensures the uniformity of distribution of particles.

Processing

In house.

We offer customers a wide array of processing services on-site including centerless grinding, CNC cylindrical grinding, CNC internal grinding, wire EDM, and laser etching, etc.

OEM Custom Service

We can develop grades as per your requirement and make the same shape as your drawing. Laser marking and neutral package are also available for your benefits.

The Grade

Grade | Density | TSR | Hardness | Grain Size |

| MT15 | 14 | ≥3000 | ≥87.5 | 1.6 |

| MT650 | 13.9 | ≥3700 | ≥89.5 | 0.8 |

| MT20 | 14.2 | ≥3500 | ≥90 | 0.5~1.5 |

| YG6 | 14.8 | ≥1670 | ≥89.5 | 0.5~1.5 |

| YG6X | 14.8 | ≥1560 | ≥91 | 0.5~1.5 |

| YG8 | 14.7 | ≥1840 | ≥89 | 0.5~1.5 |

Tungsten Carbide is a hard but brittle ceramic material which generally contains 6% to 10% cobalt, forms a tough Cermet (Ceramic-Metal). We develop material for use in cutting tools and electrolysis such as electrodes in EDM. All these uses require tungsten carbide to have a structure consists of particle crystals of a few microns in size within a ductile metal matrix. The matrix structure can withstand the high compressive stresses imposed during cutting, as well as having good wear at any temperatures. On top of that, tungsten carbide has a high resistance to thermal shock, so it is tolerated to severe temperature fluctuation.

In a nutshell, qualified tungsten carbide plate should include these following properties,

- excellent red toughness

- high hardness

- good wear resistance

- high elastic modulus

- high strength

- good chemical stability and corrosion-proof

- Low impact toughness

- low expansion coefficient

- Nearly identical thermal conductivity to ferrous metal.

Due to raw tungsten carbide material sourced from Germany and our stringent quality control, our tungsten carbide products competently engage in many industries, such as:

- Chemical

- Electric power

- Mechanical machining

- Metallurgy

- Automobile industry