Blasting cleaning process in the processing of cemented carbide inserts

With the rapid development of the industry, modern high-speed machining and automated machine tools put forward higher requirements for tool performance and stability. Cemented carbide is widely used in the production of blades due to its high hardness, wear resistance, strength and toughness, heat resistance and corrosion resistance. Carbide inserts have complex production processes, and a critical process in the sandblasting process directly affects the adhesion strength and appearance of the blade coatings. Service life plays a decisive role.

Sandblasting process

Sandblasting is divided into dry blast cleaning and wet blast cleaning. Dry blast cleaning is a kind of cleaning method formed by compressed air directly spraying the sand material onto the surface of the workpiece; wet blast cleaning is a kind of cleaning formed by the compressed air driving the mixture of sand and water to the surface of the workpiece. Processing methods.

Usually, the ordinary blade (with) is cleaned by dry blast cleaning after sintering, and the CNC blade (with) coating is cleaned by wet blast cleaning. After the ordinary blade is sintered, the surface is uneven and has impurities. It is usually cleaned with coarse white corundum. After sandblasting, it can effectively remove impurities and obtain a uniform surface. Wet blast cleaning is known as the most environmentally friendly blast cleaning. It is suitable for processing all kinds of carbide tools, no dust. It is a kind of PVD and CVD blade coating technology. The wet blast cleaning process is abroad. Has been widely used in the cemented carbide industry. The application of wet blast cleaning on carbide inserts is embodied in three aspects:

1.Blade (with) surface roughening cleaning

Wet blast cleaning can make the surface of cemented carbide inserts evenly rough before coating. Abrasives are usually made of coarse white corundum. After cleaning, the desired roughness value can be obtained, and the residual compressive stress on the surface of the material can be reduced. Reducing the Co content on the surface of the material, removing the carbide phase of the  blade of the cemented carbide insert, and the PVD and CVD deposited coating after the wet blasting pretreatment improves the bonding force between the coating and the substrate interface. The wear resistance of the layer and the service life of the blade are significantly improved, and the cutting performance of the coated blade (with) is improved.

blade of the cemented carbide insert, and the PVD and CVD deposited coating after the wet blasting pretreatment improves the bonding force between the coating and the substrate interface. The wear resistance of the layer and the service life of the blade are significantly improved, and the cutting performance of the coated blade (with) is improved.

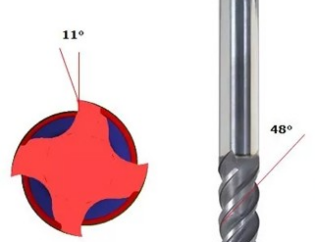

2.Blade (with) cutting edge passivation cleaning

Blade cutting technology is one of the effective measures to improve tool life and reduce tool consumption. Its economy and technical improvement are essential, which further promotes the improvement of cutting machining level in China and reduces the cutting performance of foreign tools. gap. CVD coated inserts (with) require passivation of the cutting edge of the tool before coating. The cutting edges of the CNC machine tools and production lines imported from abroad have all been passivated. Practical research shows that the tool edge passivation can effectively extend the tool life by 200% or more, greatly reducing the cost of the tool and bringing huge economic benefits to the user.

The conventional passivation process usually uses a normal grinding wheel or a diamond grinding wheel to sharpen the blade (with) a cutting edge, and the edge after the sharpening has a microscopic notch of a different degree, that is, a micro chipping and a kerf. The former can be observed with the naked eye and an ordinary magnifying glass. The latter can be observed with a microscope of 100 times (with a 0.010 mm line) microscopic gap generally ranging from 0.01 mm to 0.05 mm, and severe cases up to 0.1 mm or more. The micro-notch of the cutting edge of the tool is easily expanded during the cutting process, which accelerates tool wear and damage.

Wet blasting passivation cleaning is usually done with fine white fused alumina, which has been tested successfully and is in use. The purpose of wet blasting passivation is to solve the defect of the micro-notch of the cutting edge of the tool after sharpening, which reduces or eliminates the front value, effectively improves the edge strength, improves the tool life and the stability of the cutting process. The passivated blade improves the quality of the coating, reduces the edge value, and improves the robustness and longevity of the coating. There are many factors that affect tool cutting performance and tool life, in addition to tool material, tool geometry, tool structure, and cutting amount optimization.

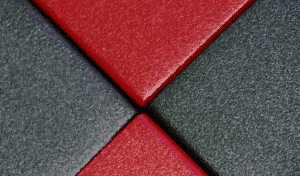

3.Blade (with) coating polishing

After the cemented carbide insert (with) coating, the surface of the coating is dull and the appearance is normal. It is cleaned with wet blasting and cleaned with fine white corundum or glass beads to further refine the surface of the coating, giving the surface a metallic luster, achieving a beautiful glazing effect and improving the product appearance.